PAM Review: Energy Science & Technology, Vol. 5, 2018

ISSN 2205-5231 | Published by UTS ePRESS | https://epress.lib.uts.edu.au/student-journals/index.php/PAMR/index

Optimisation Principles for Photovoltaic/Thermal Hybrid Solar Systems, a Meta Study

Richard Shin1*, Jose Regis Salcedo2 and Cheng Min Wang3

University of Technology Sydney, Faculty of Science, PO Box 123, Ultimo NSW 2017, Australia

1 Richard.Shin@student.uts.edu.au

2 JoseRegis.Salcedo@student.uts.edu.au

3 ChengMin.Wang-1@student.uts.edu.au

Corresponding author: Richard Shin, University of Technology Sydney, Faculty of Science, PO Box 123, Ultimo NSW 2017, Australia; Richard.Shin@student.uts.edu.au

DOI: http://dx.doi.org/10.5130/pamr.v5i0.1497

Citation: Shin, R., Salcedo, J. R. and Wang, C. M. 2018. Optimisation Principles for Photovoltaic/Thermal Hybrid Solar Systems, a Meta Study. PAM Review: Energy Science & Technology, Vol. 5, pp. 66-79. http://dx.doi.org/10.5130/pamr.v5i0.1497

© 2018 by the author(s). This is an Open Access article distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0) License (https://creativecommons.org/licenses/by/4.0/), allowing third parties to copy and redistribute the material in any medium or format and to remix, transform, and build upon the material for any purpose, even commercially, provided the original work is properly cited and states its license.

Abstract

Photovoltaic/Thermal hybrid (PVT) systems have shown promise as a viable commercial and private source of renewable energy. The purpose of this meta study is to combine contemporary research findings in the area of Photovoltaic (PV) and Photovoltaic/Thermal Hybrid solar systems and attempt to offer general optimisation principles for future PVT devices. Design parameters with which we attempt to optimise through will include PV material choice, CPC inclusion and system temperature optimisation for operational lifetime gain and power yield. It was found that we can combine CPC, closed glass design, spiral web flow and m>0.003kg/s to optimise the c-SI based systems and obtain an overall PVT efficiency gain of 5.5±1.6%, and that mass flow rates exceeding 0.003 kg/s can increase longevity by 80% on average and increase electrical efficiency by 1.2% when compared to conservative lower mass flow rates. Hydrogenated amorphous silicon systems were also deemed to create less high-quality energy and overshooting required thermal needs when using personal/private power statistics as selection criteria.

Keywords

Photovoltaic/Thermal Hybrid, PVT, Optimisation, Design, Thermodynamics, Solar Energy, Solar Concentrators, Solar Cell Degradation, CPVT

| Nomenclature | |

|---|---|

| PV | Photovoltaic |

| PVT | Photovoltaic/Thermal Hybrid |

| CPC | Compound Parabolic Concentrator |

| C | CPC Scalar concentration factor |

| a-Si:H | Hydrogenated amorphous silicon |

| c-Si | Mono – crystalline silicon |

| P-Si | Poly – crystalline silicon |

| ηPVT | Electrical collection efficiency of the PV |

| ηTh | Thermal collector efficiency |

| Ta | Ambient temperature |

| α | Resistance/temperature coefficient (expressed in % per Kelvin) |

| Eg | Band gap energy |

| m | Mass flow rate (kg/s) |

Introduction

There has been growing interest and research effort into the optimisation of PVT solar collector systems as they are quite simple and cost-effective systems that are easily integrated into buildings, making them more readily useable for commercial and personal on-site energy production. This provides an economic tradeoff over higher quality multi-junction solar cell systems which are undeniably the better system but not at a point where production can be industrialised for widespread use and are also susceptible to defect failures. This meta study has been conducted in order to collate design and optimisation elements between different branches of PVT research that have not been consolidated experimentally.

PVT systems are a combination of traditional single junction photovoltaic systems and solar thermal systems. The basic skeleton for any PVT system is outlined in Figure 1 below.

Figure 1 An example PVT system outlining the basic structure for how it collects both electrical (component 3) and thermal energy (component 6). Image from source [12]

The basic premise is that these systems provide both electric energy (typically referred to as “high quality” energy in literature, as it can be applied to more tasks or even re-routed to the grid) collected from the sun and also absorb what the photovoltaic component cannot absorb through the thermal back sheet (component 6 in Figure 1) to heat a working fluid that can be stored for later use.

Photons of light with sufficient energy to promote electrons in semiconductor materials (referred to in the literature as surpassing the band gap energy Eg) interacts with the semiconductive material and takes electrons from the valence band to the conduction band. This process creates an electron-hole pair, of which the electron must thermalise until it can recombine with the hole it created in the valence band. It is this electron liberation process that is used as electrical energy in all solar powered systems, by creating metal contacts between negative (electron donor) and positive (electron acceptor) type semiconductors to create a circuit.[1-11]

Conversely, light that does not have sufficient energy does not interact with the PV component, passing it and thus being collected by the thermal backplate. The backplate also collects radiative heat from the thermal relaxation of promoted electrons that absorbed photons of light larger than Eg that are preparing to recombine in the PV component of the system. [3,4,7] The spectral percentage of sunlight that cannot be collected by Silicon (typically Eg=1.1eV) due to insufficient photon energy (that is to say, the energy of the photon is smaller than Eg) has been widely known to be 19%.[23]

Photons absorbed that are above the bandgap also do not fully contribute their entire energy to the production of electricity in a photovoltaic cell, as predicted by the Schockley-Quessier paper detailing efficiency limits.[23] The energy that exceeds the bandgap in reality turns into thermal energy as the electron needs to radiate heat in a thermal relaxation process. The trade-off here is that higher Eg materials produce higher energy electron- hole pairs but interact with a smaller spectrum of the sun, and the inverse is true for smaller Eg materials. For Silicon single junction cells, this typically results in a total electrical loss of 48% from spectral losses alone.[23,24]

Energy “Quality” and Comparison to Tandem Cells

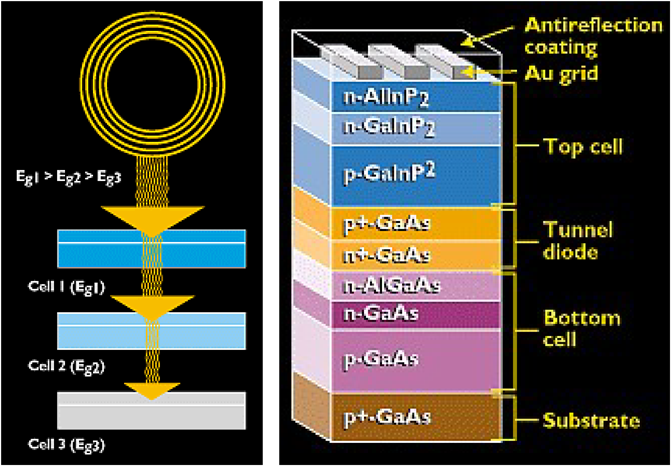

Multi Junction PV cells (also known as tandem cells) have already been developed and do see use in applications where the financial and production barrier are not an issue. These cells work by layering many different types of semiconductive material (as shown above in Figure 2), with the premise being that the high Eg material on the top layer absorbs high energy photons efficiently, letting lower energy light pass through it and liberate an electron from a lower layer with more suitable Eg.

This causes multi junction cells to have a much higher electrical collection efficiency, which is the more desired “high quality” energy that can be converted to a wider variety of thermodynamic outputs. Theoretical efficiency limits are based off how many layers a multi junction cell are comprised of and in practicality the band selection also plays a part, but two layer cells are theoretically capped at ηe=42%, three layer cells at ηe=49% and so forth with diminishing returns, with an infinite layer multi-junction cell being capped at ηe=68% in unconcentrated sunlight operation.[26]

While both theoretical and experimental results are both outperforming PVT ηe values, there are many challenges in actually implementing these for widespread use, as these systems are very prone to heat defects as the lattice points of each semiconductor layer must be matched and this can easily be ruined by heat induced defects during operation, dramatically lowering efficiency.[24-27] Production of these cells for large arrays also proves to be very costly and time expensive, thus widespread implementation as a primary private renewable is quite far off compared to PVTs which are robust and much simpler in design and production.[26,27]

Figure 2 An example PVT system outlining the basic structure for how it collects both electrical (component

PVT systems however are still useful since commercial single junction photovoltaic devices in practical use quite often have to convert the electrical energy they collect into thermal energy to heat water, leading to a dramatically lower collection efficiency for this purpose which accounts for 21% of commercial/personal household power usage and the single largest source of greenhouse gas emissions for households in Australia.[6] PVT devices overcome this conversion inefficiency by directly collecting the surplus thermal energy and dumping it into a heatsink (component 6 of Figure 2) as hot water.

Not only does this collection method increase the spectral efficiency of the collection system as a whole[1-11], but the thermal component by nature acts as a heatsink for the photovoltaic component. This allows PVT systems to double down on efficiency gains, as higher thermal output means lower PV operation temperatures, which increase PV collection efficiency as well.[3]

Typically solar cells are not only fully thermalised in real world application, but are actually operating at temperatures that are hot enough to decrease electric collection efficiency, typically operating at 40℃ above ambient temperature Ta. This is past the optimal thermalisation temperature and when PV cells tend to display more intrinsic semiconductor properties and lower electrical efficiency due to thermal resistance.[3,8]

This truth in application has led to some research looking into hydrogenated amorphous Silicon (a- Si:H) being used for the PV components as opposed to traditional mono or polycrystalline Silicon (c-Si), as the temperature coefficient for a-Si:H is typically 0.01% per Kelvin[5] compared to the c-Si value of 0.04% per Kelvin.[1-10] This is also due to the fact that a-Si:H can operate at a higher temperature, allowing the thermal working fluid to be raised to a higher temperature as well since the Second law of Thermodynamics dictates that heat can only go from a hotter body to a colder one.[5]

High temperature conditions also cause accelerated degradation of the photovoltaic system through the means of thermally activated degradation processes, which include polymer degradation and collector contact corrosion. This typically results in a PV collection efficiency degradation of 1.3%-2% per year in hot climates such as India and Africa, with the higher range of values coming from countries with more humid conditions causing moisture intrusion degradation.[8,11] This degradation dramatically lowers the expected service time of a module compared to colder climates (0.2-0.8% per year)[8,10], leading to a typical service life of 10-15 years for a single junction PV collector in these hot climates when using the criteria that a performance loss of 20% is considered a failure.[9]

An overall performance indicator of the PVT system can be expressed as:

Where ηTh is calculated as the thermal collection efficiency with respect to the the energy available after photovoltaic interaction, not to be confused with the collection efficiency with respect to the energy available from the radiation source.

Thermal Parameters to address.

For most conventional PVT systems, water collectors are used to remove heat from the thermal component. In this hybrid open/closed system, water is pumped around the system at a specified mass flow rate m, which cools the PV component of the system (so long as the liquid is cooler than the cell) and can then be stored for later use. This differs from other liquid thermal collection methods such as closed loop systems where a working fluid such as glycol or mineral oil are used and transferred to a heat exchange system when needed, so that liquid never leaves or enters the system.

Insulating the stagnant air surrounding the PV cell from the surrounding through glass coverings is also another design parameter investigated, as this aims to reduce conduction loss from the stagnant air and the thermal collection system to the surroundings.[1] It has also been hypothesized in PVT design that the glass cover may also be reflecting light from the cell and lowering some of the electrical efficiency and thus some thermal efficiency as high energy light bouncing off the front panels are simultaneously not creating electron-hole pairs and thermal energy from relaxation processes.

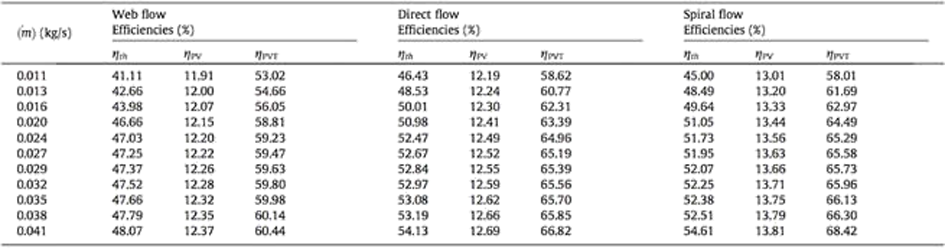

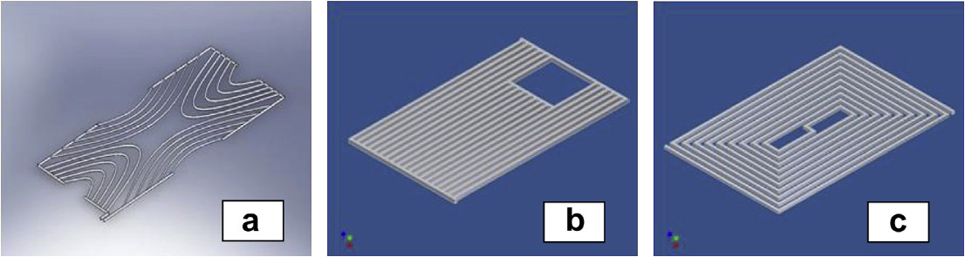

Geometric design considerations of the piping in the thermal system must also be considered as maximising contact area and minimising heat loss to surroundings is pivotal. The three main geometric design types for the thermal absorbers were as follows; Web Flow, Direct Flow, Spiral Flow.[1] The main parameters each design focused on was maximising path length of the water for spiral flow, minimising contact time over max area for direct flow and a compromise between the two with the web flow designs, which are shown in Figure 1.

Figure 3 (a)Web Flow (b)Direct Flow (c)Spiral Flow [1]

As mentioned before, a-Si;H has garnered attention in the PVT research efforts as another commercially viable photovoltaic source, as the high operation heat and low α values associated with a-Si:H allows it to heat the working fluid to a higher temperature above Ta and work as a more symbiotic hybrid system.[5,13,14]

Photovoltaic Parameters to address

The Photovoltaic (PV) component of the system directly converts solar energy to electric energy which is more convenient to use (hence the term ‘high quality’ energy often used in literature), however it has a much lower efficiency than the thermal collector.[1-11] Due to the real life working condition affecting efficiency of PV cells, a cooling system is necessary for the PV cells to improve the performance, as they typically have a resistivity/temperature coefficient of 0.04% per Kelvin.[1-11] A simple way of cooling PV cells is by increasing the working fluid mass flow rate (m) of the hybrid system, however it has a critical point while it may cause the decreasing of the thermal collectors efficiency, while also lowering the output water temperature.

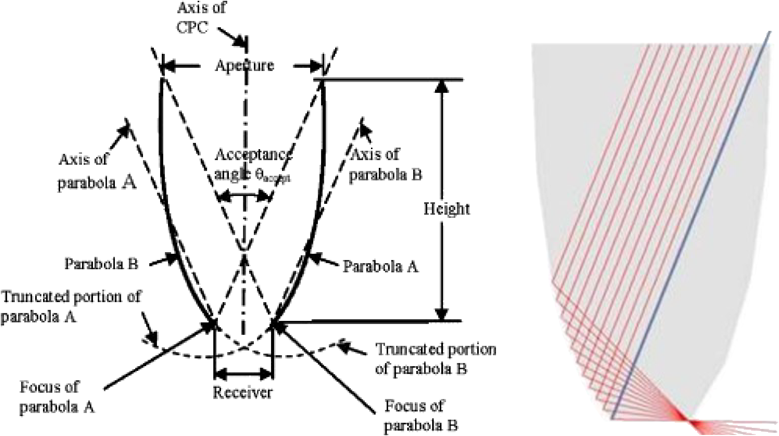

Figure 4 An example of a CPC fitted PVT system

Compound Parabolic Concentrators (CPCs) can also be employed to increase the amount of solar radiation per unit area a cell can receive, which normally introduces heat defects and accelerates degradation in a system without adequate cooling measures[3,5,7,8], but in the case of PVT systems, this allows the cell to not only get more light, but we can also control the temperature of the system by adjusting m which should counteract the extra heat that could cause accelerated defects.[2] This should also allow the output temperature of the working fluid to reach higher temperatures, as the cell would otherwise be running at much higher temperatures above Ta.

CPCs work by concentrating rays that would otherwise not hit the array into more localized pockets within the PVT system as shown in Figure 5. While an overall expression of concentration for the entire system within the CPC is known to be:

This expression typically leads to C>2 values when using θaccept as shown in Figure 5 but by referring to the ray diagram, this concentration is not uniform throughout the cell, and the localized pockets of high concentration cause the overall efficiency to not increase linearly with C as local pockets receiving concentrated radiation may be operating at much higher temperatures than the bulk system.[16-19,29]

Figure 5 A ray diagram of a CPC, the most important parameter of which is θaccept which determines concentration factor C.[29]

Methods

In this meta study, searches were performed through several databases; ProQuest Science & Tech, SCOPUS and Google Scholar. The initial focus was categorised to photovoltaic systems and their operating numbers (efficiencies, current limitations, etc.) to help identify technological inefficiencies in the system. Extra research was then done on current and proposed designs to increase solar cell efficiencies since some designs only achieved a maximum efficiency of 46% (Best Research-Cell Efficiencies NREL). These designs include Photonic Photovoltaic, convex photovoltaics, multi junction cells and Thermal Photovoltaics. Photonic, convex and multi junction photovoltaics have the disadvantage of cost in manufacturing and operation while photonic designs are theoretical with no supportive evidence, convex designs have been tested but are costly, and multi junction cells only slightly increase coverage in the solar spectrum while ignoring possible benefits from thermal heat.

For this study, research from 2010 onwards were used to provide the information and data we used to inform decisions on optimisation parameters, with key search terms including: Thermovoltaics, Photovoltaic / Thermal, Photovoltaic efficiency, efficiency, PVT, single junction PVT and Photovoltaic Thermal Design. While economic and financial numbers are part of the research effort and real-world application of PVT usage, papers that focused specifically on or had an economic lens were avoided, as this paper is designed more to be a scientific meta study written by people who would be non-experts in analysing the economic impact.

Selection criteria for a-si:H and c-Si systems based on energy profiles between the different systems were based on the 21% of household power consumption as thermal statistic of source [6] and average power consumption as reported by Ausgrid in source [30]. However, for statistics and well established percentages and theoretical limits widely referred to throughout the literature, the year restriction did not apply as many of the theoretical concepts underpinning solar cell efficiency have been around for many decades (such as the Schockley-Quessier Limit and solar spectrum data).

Any statistics collected from the papers that were a part of the 2010+ cutoff were analysed in Excel by normalizing for sample size when comparing and collating efficiency values between experiments. When timed data was presented, the average value for efficiency was taken for the data captured in order to compare between papers.

Results and Discussion

Water Collector Design

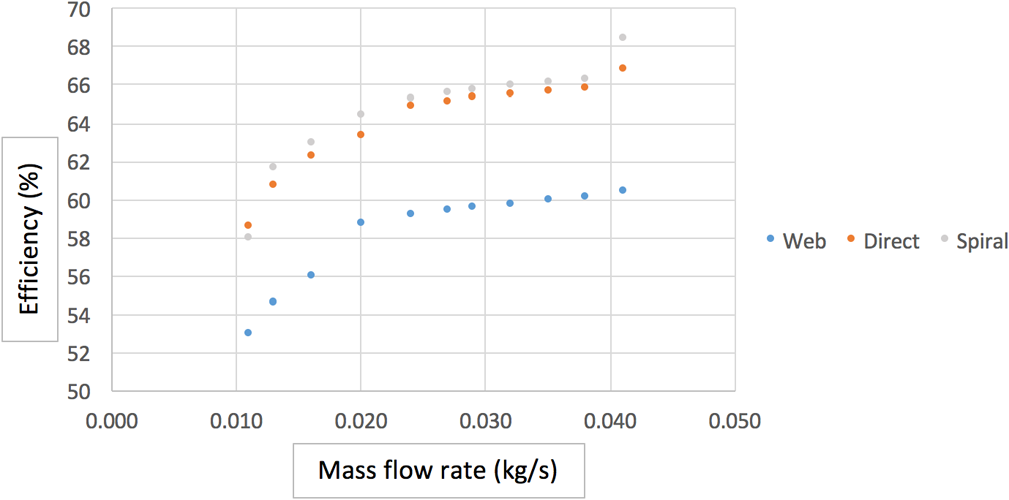

In terms of physical design parameters to address, Fudholi et. al found that across all systems, ηTh increases as mass flow rate m of water increases. This increase in thermal efficiency is directly related to the reduction of both operating temperatures of the systems and internal cell temperature, increasing PV electrical collection efficiency.[1-8] This is of course, at the trade off of the increased work required to pump the water around the system.

Table 1 Mass Flow rate vs Efficiency values. [1]

Figure 6 PVT efficiency plotted against mass flow rate m from Table 1.

Between Web Flow, Direct Flow and Spiral Flow designs, Spiral Flow produced the best thermal collection efficiency at 68.4%, most likely due to a maximization of area coverage and a minimisation of path length, increasing the collection area and reducing thermal loss to surroundings. Spiral flow outperformed Direct Flow by 1.6%, which is significant as most schematics found in the papers resembled direct flow the most in terms of water flow design. This assumption that current non specified thermal designs are operating on direct flow-like systems will be used for the conclusion.

1.1 – Thermal Parameters

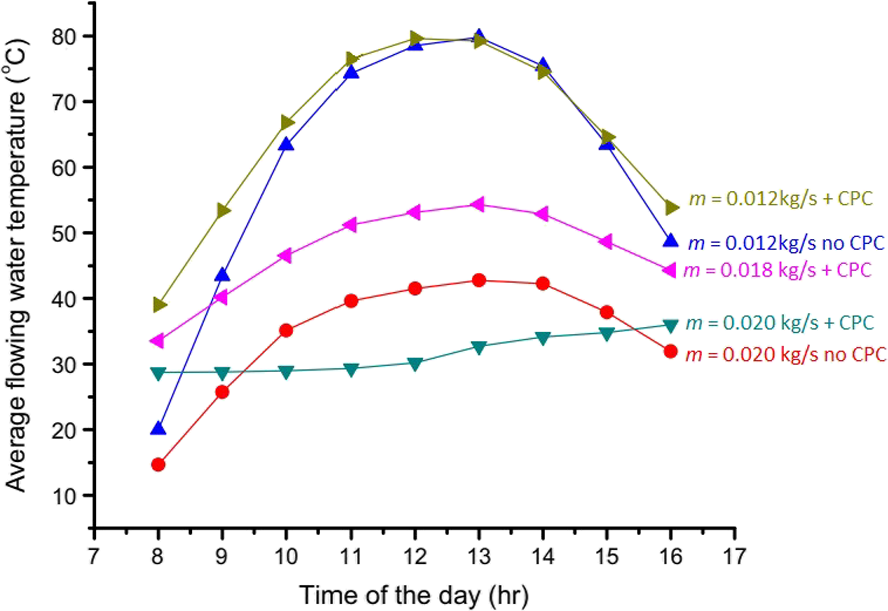

In Figure 7 we can see that the output temperature of the water is affected mostly in terms of temperature stability in systems that implement the CPC, and the mean temperatures during operation times were typically 1.7±1% greater in CPC versus non CPC systems (on a Kelvin scale). Whilst the uncertainty shows that it wasn’t guaranteed amongst all trials to improve significantly, this can be attributed to both the localized high heat conversions that are inherent to CPCs, different weather conditions and reasonable statistical variance for something as stochastic as solar radiance in outdoor experiments.

Sources [1,2,7,17] also reported an average 6.1±0.4K decrease in PV operation temperature for m rates greater than 0.003kg/s when compared to an m of 0.0012kg/s which is the lowest value any paper provided. This corresponds to a operational lifetime gain of 80% as outlined by X. Sun’s analysis.[3]

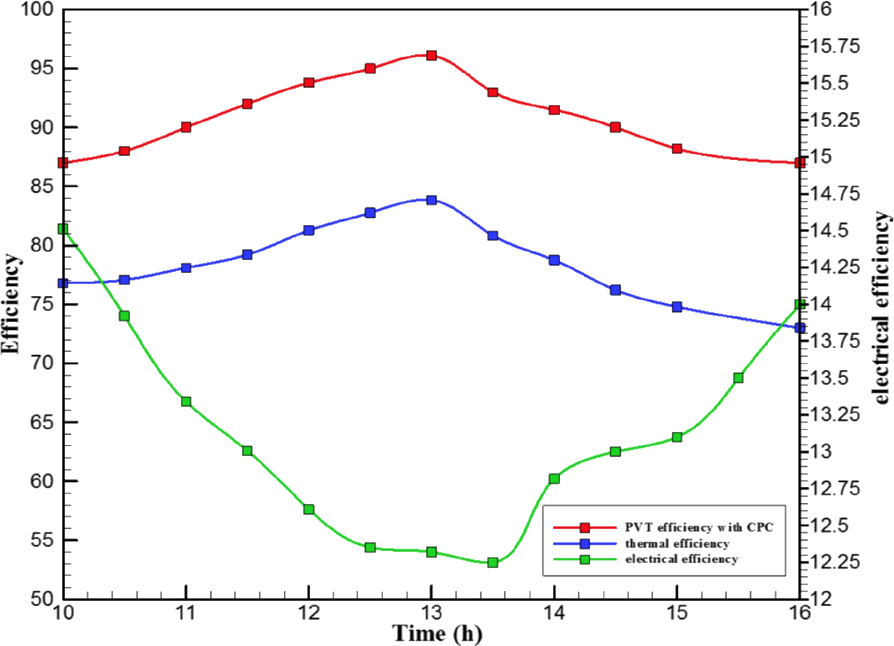

The results shown above in Figure 8 also reinforce the notion that the addition of CPC is a benefit for PVT thermal stability. Despite an electrical efficiency drop, the total system can still collect more total energy, albeit not at a linear scale that increasing C would have us believe. This was due to local C values at some points of the system reaching as high as 25 despite average C values being within the range of 2-3 for the entire system, causing local pockets of very high resistance and temperature PV collection.[16-20]

Figure 7 A comparison of selected experimental findings from papers [1, 2, 7, 17] where matching mass flow rate m was the selection criteria

Figure 8 Hourly variation of electric, thermal and PVT efficiency for a PVT solar cell with CPC with C=2.3.[2]

It was also determined that between closed and open glass designs, the efficiency gain was minimal for the overall system (usually less than 1%) when using closed glass systems, but in terms of energy profile, it was typically ηPV losing 2±1% for an ηTh gain of 3±1% when implementing closed glass systems.[2,3,7,8] However, the potential ηPV gain of open glass design is not conducive to durable systems as the open glass design accelerates corrosion and requires maintenance to remove debris from the array.[8]

3.3 – Photovoltaic Design

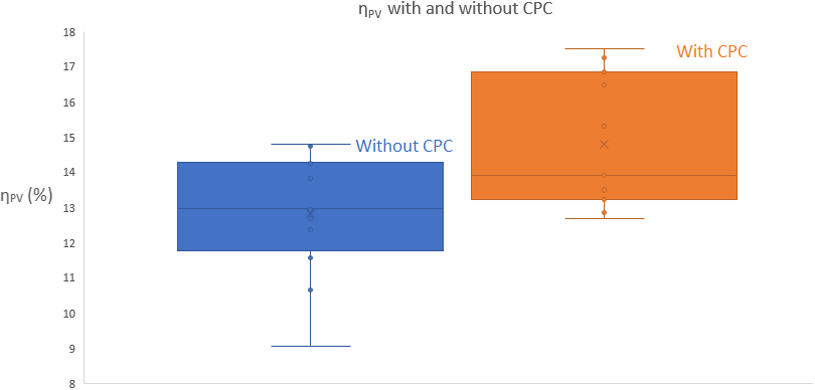

Collating the PV performance results from sources [1-11] showed that a-Si:H shows moderate promise at being able to operate at high temperatures more conducive to an efficient thermal source in application, while also providing a 7.9% gain in overall PVT efficiency when compared to c-Si modules operating at the temperature range between 50-100°C, which is shown to be a realistic operating range as PV modules generally operate at 40°C above ambient temperature.[3,5,8]

Despite this however, the actual energy profile of a typical a-Si:H system is typically 9.1%[5,13] electrical energy in experiments[5,13], compared to the determined average of 13% across non CPC c-SI systems[1-3, 8-10]. Overall efficiency was determined to be 72.3%, meaning that 63.2% of an a-Si:H system is low quality thermal energy that cannot be converted into work (and thus electricity too).

Figure 9 The ηPV results collected from experimental papers past 2010.

The limiting factor of requiring to anneal a-Si:H defects after long operation can also be circumvented by using them in conjunction with solar concentrators, which can raise the operating temperature and electrical efficiency by 3% [2], and mounting the a-Si:H closer to the thermal backplate, allowing the a-Si:H to anneal on a daily cycle in ideal conditions which is more than often enough for it to get closer to conventional c-SI PV modules.[5]

As shown in Figure 9, implementing CPC in PVT systems resulted in an average ηPV of 14.8±1.4% compared to the 13±1.2% in non CPC systems. Some of the ηPV gained by implementing CPC is offset by the hotter running temperatures and localised C values being ~10 times higher than the calculated average as discussed prior.

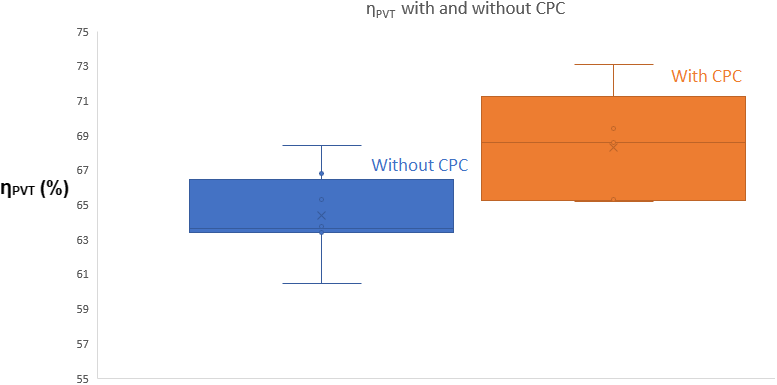

Figure 10 The ηPVT results between all papers. Without CPC average = 64.4%, with CPC average = 68.3%

In reference to the data displayed by Figure 10, the overall PVT performance with CPC was determined to be on average 3.9% when compared to non CPC systems, with ηPV accounting for 1.8% of that increase and ηTh accounting for 2.1%.

3.4 – Selection criteria between a-Si:H and c-Si PVT systems

By using the average of NSW data presented in Figure 11, it was found that the average daily power consumption was 15.7kWh/day (or 5.65x107 J/day) when normalised for population of each suburb. This means that 21% of this energy (3.297kWh/day 1.19x107 J/day) is required to run thermal operations such as heating water according to.[6]

Taking an average Sydney c-Si PV power output of 3.9kWh/day of high quality electricity[30], we find that a PVT system in the same conditions (which produce roughly 5 times as much thermal energy) would produce much more than the required 3.297kWh/day that the average household needs, thus diminishing the benefit that a-Si:H systems greatly, despite their larger overall ηPVT. It is important to note that the increased ηPV of the c-Si cells can be rerouted to the grid, whereas excess thermal energy can not be put into the grid and must be consumed on site.

Figure 11 Average Household power consumption per day as reported by Ausgrid.[30] The individual data points are population averages for different regions within NSW such as Hunter Valley, Sydney, Newcastle etc.

Conclusions

The research investigated shows that future commercial devices can adopt new design factors such as a-Si:H solar cell fabrication and spiral flow thermal piping design, and maintain current closed glass designs to maximise total PVT efficiency to 72.3% by adopting spiral flow water design, which maximises surface area and minimises water path length to increase thermal yield, bypassing the 90-95% conversion efficiency of going from electric to thermal in a heating application.[28]

While implementation of a-Si:H does increase ηPVT, the proportion of high quality electrical energy compared to thermal energy only makes it suitable for select applications where thermal energy is needed. Using the statistic outlined in [6] concludes that for personal use and data gathered from [30], a-Si:H PVT systems provide no tangible benefit for private/personal use as they overproduce thermal energy which must be used on site and cannot be rerouted to the grid.

In using that criteria from [6], we then suggest implementing closed glass c-Si PVT systems with Spiral Flow, CPT and m values larger than 0.003kg/s, which should add 5.5±1.6% to ηPVT for conventional c-Si PVT systems and increase system longevity by 80% at minimum.

Acknowledgments

We would like to thank Dr. Jurgen Schulte, Dr. Martin Bell, Blake Regan and Joshua Pritchard for their guidance and feedback throughout the process of creating this meta study.

References and Notes

1. Fudholi A, Sopian K, Yazdi M, Ruslan M, Ibrahim A, Kazem H. Performance analysis of photovoltaic thermal (PVT) water collectors. Energy Conversion and Management. 2014;78:641-651. https://doi.org/10.1016/j.enconman.2013.11.017

2. Jaaz A, Hasan H, Sopian K, Kadhum A, Gaaz T, Al-Amiery A. Outdoor Performance Analysis of a Photovoltaic Thermal (PVT) Collector with Jet Impingement and Compound Parabolic Concentrator (CPC). 2018.

3. Sun X, Silverman T, Zhou Z, Khan M, Bermel P, Alam M. Optics-Based Approach to Thermal Management of Photovoltaics: Selective-Spectral and Radiative Cooling. IEEE Journal of Photovoltaics. 2017;7(2):566-574. https://doi.org/10.1109/JPHOTOV.2016.2646062

4. Osterloh F. Maximum Theoretical Efficiency Limit of Photovoltaic Devices: Effect of Band Structure on Excited State Entropy. The Journal of Physical Chemistry Letters. 2014;5(19):3354-3359. https://doi.org/10.1021/jz501740n

5. Pathak M, Pearce J, Harrison S. Effects on amorphous silicon photovoltaic performance from high-temperature annealing pulses in photovoltaic thermal hybrid devices. Solar Energy Materials and Solar Cells. 2012;100:199- 203. https://doi.org/10.1016/j.solmat.2012.01.015

6. Energy | YourHome [Internet]. Yourhome.gov.au. 2018 [cited 22 May 2018]. Available from: http://www.yourhome.gov.au/energy

7. Sharaf O, Orhan M. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part I – Fundamentals, design considerations and current technologies. Renewable and Sustainable Energy Reviews. 2015;50:1500- 1565. https://doi.org/10.1016/j.rser.2015.05.036

8. All-India Survey of Photovoltaic Module Degradation: 2013 [Internet]. Gurgaon: IIT Bombay; 2018 [cited 22 May 2018]. Available from: http://www.ncpre.iitb.ac.in/research/pdf/All_India_Survey_of_Photovoltaic_Module_Degradation_2013.pdf

9. Photovoltaic Degradation Rates — An Analytical Review [Internet]. Springfield, VA: Progress in Photovoltaics: Research and Applications; 2018 [cited 22 May 2018]. Available from: https://www.nrel.gov/docs/fy12osti/51664.pdf

10. Ishii T, Takashima T, Otani K. Long-term performance degradation of various kinds of photovoltaic modules under moderate climatic conditions. Progress in Photovoltaics: Research and Applications. 2010;19(2):170-179. https://doi.org/10.1002/pip.1005

11. Quansah D, Adaramola M, Takyi G, Edwin I. Reliability and Degradation of Solar PV Modules—Case Study of 19-Year-Old Polycrystalline Modules in Ghana. 2018.

12. Renewable Energy Now Provides More Electricity Than Nuclear in the US [Internet]. Steemit.com. 2017 [cited 22 May 2018]. Available from: https://steemit.com/news/@johnniec/renewable-energy-now-provides- more-electricity-than-nuclear-in-the-us

13. Pathak M, Girotra K, Harrison S, Pearce J. The effect of hybrid photovoltaic thermal device operating conditions on intrinsic layer thickness optimization of hydrogenated amorphous silicon solar cells. Solar Energy. 2012;86(9):2673-2677. https://doi.org/10.1016/j.solener.2012.06.002

14. Frigeri C, Serényi M, Szekrényes Z, Kamarás K, Csik A, Khánh N. Effect of heat treatments on the properties of hydrogenated amorphous silicon for PV and PVT applications. Solar Energy. 2015;119:225-232. https://doi.org/10.1016/j.solener.2015.07.004

15. Daghigh R, Ibrahim A, Jin G, Ruslan M, Sopian K. Predicting the performance of amorphous and crystalline silicon based photovoltaic solar thermal collectors. Energy Conversion and Management. 2011;52(3):1741-1747. https://doi.org/10.1016/j.enconman.2010.10.039

16. Proell, M. and Hilt, M. (2014). The Significance of the Fluid to PV Thermal Coupling in a CPC PVT Collector. Energy Procedia, 57, pp.3120-3129. https://doi.org/10.1016/j.egypro.2015.06.067

17. Elsafi, A. and Gandhidasan, P. (2015). Comparative study of double-pass flat and compound parabolic concentrated photovoltaic–thermal systems with and without fins. Energy Conversion and Management, 98, pp.59-68. https://doi.org/10.1016/j.enconman.2015.03.084

18. Tripathi, R., Tiwari, G. and Al-Helal, I. (2016). Thermal modelling of N partially covered photovoltaic thermal (PVT) – Compound parabolic concentrator (CPC) collectors connected in series. Solar Energy, 123, pp.174-184. https://doi.org/10.1016/j.solener.2015.11.014

19. Proell, M., Osgyan, P., Karrer, H. and Brabec, C. (2017). Experimental efficiency of a low concentrating CPC PVT flat plate collector. Solar Energy, 147, pp.463-469. https://doi.org/10.1016/j.solener.2017.03.055

20. Aste, N., Leonforte, F. and Del Pero, C. (2015). Design, modeling and performance monitoring of a photovoltaic–thermal (PVT) water collector. Solar Energy, 112, pp.85-99. https://doi.org/10.1016/j.solener.2014.11.025

21. Chow, T. (2010). A review on photovoltaic/thermal hybrid solar technology. Applied Energy, 87(2), pp.365-379. https://doi.org/10.1016/j.apenergy.2009.06.037

22. Karathanassis, I., Papanicolaou, E., Belessiotis, V. and Bergeles, G. (2013). Multi-objective design optimization of a micro heat sink for Concentrating Photovoltaic/Thermal (CPVT) systems using a genetic algorithm. Applied Thermal Engineering, 59(1-2), pp.733-744. https://doi.org/10.1016/j.applthermaleng.2012.06.034

23. Shockley, W. and Queisser, H. (2018). Detailed Balance Limit of Efficiency of p-n Junction Solar Cells.

24. Solanki, C. and Beaucarne, G. (2007). Advanced solar cell concepts. Energy for Sustainable

25. Development, 11(3), pp.17-23. https://doi.org/10.1016/S0973-0826(08)60573-6

26. Knier, G. (2018). How do Photovoltaics Work? | Science Mission Directorate. [online] Science.nasa.gov. Available at: https://science.nasa.gov/science-news/science-at-nasa/2002/solarcells [Accessed 22 May 2018].

27. Vos, A. (1980). Detailed balance limit of the efficiency of tandem solar cells. Journal of Physics D: Applied Physics, 13(5), pp.839-846. https://doi.org/10.1088/0022-3727/13/5/018

28. Dimroth, F., Grave, M., Beutel, P., Fiedeler, U., Karcher, C., Tibbits, T., Oliva, E., Siefer, G., Schachtner, M., Wekkeli, A., Bett, A., Krause, R., Piccin, M., Blanc, N., Drazek, C., Guiot, E., Ghyselen, B., Salvetat, T., Tauzin, A., Signamarcheix, T., Dobrich, A., Hannappel, T. and Schwarzburg, K. (2014). Wafer bonded four- junction GaInP/GaAs//GaInAsP/GaInAs concentrator solar cells with 44.7% efficiency. Progress in Photovoltaics: Research and Applications, 22(3), pp.277-282. https://doi.org/10.1002/pip.2475

29. Smarterhouse.org. (2018). Replacing your Water Heater | Smarter House. [online] Available at: https://smarterhouse.org/water-heating/replacing-your-water-heater [Accessed 22 May 2018].

30. Mgbemene, C., Duffy, J., Sun, H. and Onyegegbu, S. (2010). Electricity Generation From a Compound Parabolic Concentrator Coupled to a Thermoelectric Module. Journal of Solar Energy Engineering, 132(3), p.031015. https://doi.org/10.1115/1.4001670

31. Ausgrid.com.au (2017). Average Electricity Use Data to share. [online] Available at: https://www.ausgrid.com.au/Common/About-us/Corporate-information/Data-to-share/Average-electricity- use.aspx [Accessed 22 May 2018].