Investigation of thermodynamic factors influencing Thorium reactor efficiencies

Jarrod Glass1,*, Anthony Burgess2 and Takuya Okugawa3

Faculty of Science, University of Technology Sydney, P.O. Box 123, Australia

1E-mail; jarrod.glass@student.uts.edu.au

2E-mail; anthony.burgess@student.uts.edu.au

3E-mail; takuya.okugawa@student.uts.edu.au

* Author to whom correspondence should be addressed; E-Mail: jarrod.glass@student.uts.edu.au

Received: 25/5/2015 / Accepted: 29/5/2015 / 1/6/2015:

Abstract:

In this meta-study, the major forms of thorium based nuclear reactors were compared using thermodynamic parameters to find which reactor type holds the highest thermodynamic efficiency and hence, determine which reactor would be most beneficial to research further and implement for energy production. Our study found that molten salt reactors had the best thermodynamic efficiency and also runs at one atmospheric pressure, making it safer than conventional water reactors. The findings in this study show molten salt reactors would be the most efficient reactor to replace standard water reactors, which dominate the market in use of nuclear energy production. This study found a strong link between the thermal efficiency of the plant and the pressure and temperature at which it runs. Reactor core volumes also appeared to have a small effect on the efficiencies. Power flux density was calculated for each style of reactor and compared to other parameters but no distinct relationship was found between them.

Keywords: Thorium; Thermodynamics; efficiency; Power flux density; Nuclear;

Copyright: © 2015 by the authors. This article is distributed under the terms and conditions of the Creative Commons Attribution license (https://creativecommons.org/licenses/by/4.0/).

DOI: http://dx.doi.org/10.5130/pamr.v2i0.1393

1. Introduction

There are as many as 7 major types of thorium reactors which all boast many benefits over one another [1]. The reactors we will be investigating include; Heavy Water Reactors (PHWRs), Advanced Heavy Water Reactors (AHWR), which is a type of PHWR. High Temperature Gas-cooled Reactors (HTGRs), pressurized/boiling Light Water Reactor (BWRs/PWRs), Fast Breeder Reactors (FBRs), Molten Salt Reactors (MSRs) and Accelerator Driven Reactors (ADS).

1.1- Light Water Reactors (PWR/BWR)

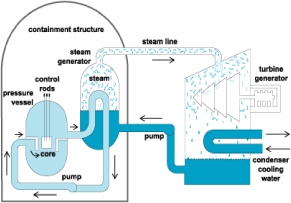

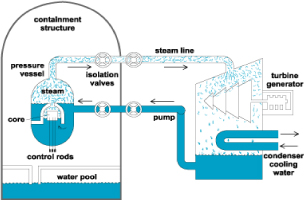

The BWR and PWR are the most common form of reactor today and commonly go by the name of the light water reactor. These reactors use a core to heat up water either in the reactor vessel as in a BWR reactor, or heating a primary water cycle, which will then heat up a secondary source of water to generate steam. This steam will then be drawn into a turbine where it generates electricity and the cycle is repeated. An example of the process for each reactor can be seen in figure 1.1 and 1.2 below. These reactors are said to operate at a maximum of 325°C and 289°C respectively and very high maximum pressures of around 15MPa for PWR and 7MPa for BWR [2]. These reactors both use the Rankine thermodynamic cycle. A study by Victoria A. Schopflin [3] showed that light water reactors can be utilised for Uranium-Thorium fuels instead of purely uranium fuels. However she noted there was no disadvantage or advantage to the two systems.

Figure 1.1 -PWR [4]

(Uses a primary and secondary loop, with the primary generate loop for cooling/heat transfer the reactor, and the secondary for energy production)

Figure 1.2 -BWR [4]

(Differs to the PWR by using one loop to cool and electricity)

1.2- Pressurized Heavy Water Reactors

Another reactor similar to the light water reactors above is the Heavy water reactor. These reactors use heavy water as a coolant system instead of normal water and are meant to provide enhanced neutron economy. Presently it has been found that this reactor would work less effectively with thorium unless the neutron economy can be increased. However the AHWR discussed below is a new PHWR which is able to fully utilize thorium. This reactor can deliver around 930MW (thermal) and utilizes the Rankine thermodynamic cycle and operates with temperatures of 260-300°C, at pressures of 10MPa [5].

1.2.2- Advanced Heavy Water Reactors

A very new reactor, which is presently being developed in India is the AHWR which aims to become the next generation of Pressurized Heavy Water Reactor. It runs at 7MPa and 450°C and uses light water to cool and heavy water as a moderator. The AHWR uses only Thorium as its fuel source [6]. It is said to operate almost at the same thermal output as its predecessor the PHWR at 920MWth and runs on the Rankine thermodynamic cycle.

1.3- High Temperature Gas-cooled Reactors (HTGRs/VHTR)

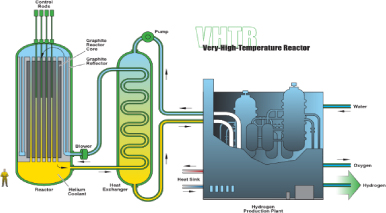

The High Temperature Gas-cooled Reactors seem to be a promising field for further research with thorium and are based on two forms; PBR (Pebble Bed Reactor) addressed below and PMR (Prismatic block reactors) addressed now. The HTGRs use a cooled gas such as Carbon dioxide or Helium to carry the heat from the reactor and graphite as a moderator. One paper states a PMR reactor which runs in the range of 700-950°C producing 200MWth [7]. Most PMR reactors will use a large block of graphite with holes for fuel and control rods. An example can be seen in figure 1.3.1.2. A beneficial component of both HTGRs, which was highlighted by Po-Jui Li et al. [8] is that the high temperature gas can be utilized for a second use in creating Hydrogen gas or other chemical synthesis as the gas is already hot enough for the process to take place. We thought it noteworthy to mention as doing this utilises a lot of the heat that would be lost, hence driving up the thermal efficiency of the system. An example of this reactor and the secondary use of the system can be seen in figure 1.3.1.

Figure 1.3.1 (HTGR including hydrogen production as secondary use of coolant) [9].

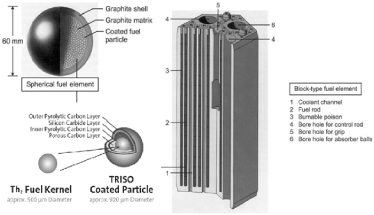

1.3.2- Pebble Bed Reactors (PBR)

The PBR is the secondary form of HTGR. However not much research has been done on these reactors as of late. This style of reactor uses numerous pellets of fuel as seen in figure 1.3.1 to sustain the nuclear reaction. Sen and Kadiroglu [10] states it operates most effectively at temperatures of 900°C and pressures of 10 MPa. These reactors are said to be quite efficient but a high majority of funding and research on this style of reactor has been stopped largely due to a 1986 incident at a test reactor and a damning 2008 report by Rainer Moormann [11], which states the reactors have improper temperature recording (actual temperature can be higher than indicated), contamination of cooling circuits and other issues. Due to this there are few advancements on this style of reactor.

Figure 1.3.2.1: Thorium fuel for Pebble Bed Reactor [12]

Right: PBR fuel, Left: PMR fuel element.

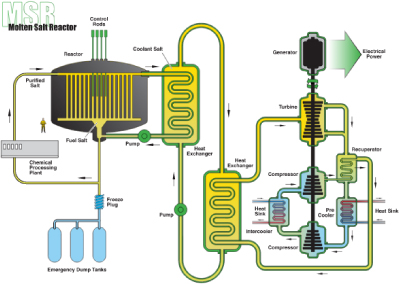

1.4- Molten Salt Reactors (MSR)

The Molten Salt Reactor is a very promising reactor based on its safety, efficiency and output. It uses molten salt to carry the heat from the reactor and can run at temperatures in the range of 500°C to 1400°C. Even more beneficial is the fact that MSRs are hypothetically meant to have little to no pressurization so ideally operate at 1atm. These reactors are also meant to be immune from meltdowns due to a safety feature that drains away the molten salts into a secure containment tank in the case of an emergency and the lack of pressurization will also prevent the plant from exploding. Molten salt reactors are known to differ in many ways to the conventional fission reactors. The main difference is that molten salt acts as a coolant, fuel and moderator. This is because the coolant circuits have the same composition as the fuel and moderator [13]. Another distinctive feature is that the temperature greatly exceeds that of a typical pressurized water reactor, where the water reactors sit at roughly 300°C and the molten salt reactors can sit in a range of 700-1400°C, where 1400°C is an extreme case, only performed by a molten salt consisting of a lithium/beryllium fluoride.

1.5-Accelerator Driven Reactors (ADR)

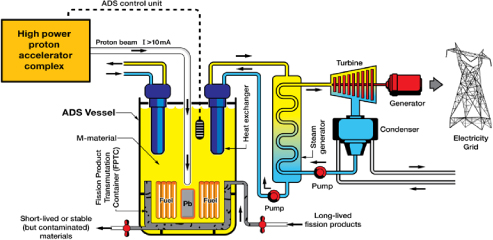

These reactors differ highly from the other reactors explored in this meta-study. An ADR uses a cyclotron to produce neutrons from heavy elements by a process known as ‘spallation’. This process uses a high-energy proton beam directed at a high-atomic number target, in which thorium can be used. The neutrons however have a lower probability of causing additional fission. Despite the lack of fission the target still requires cooling due to heating by the accelerator beam. A safety feature which many of the reactors lack is that this reactor can be simply switched off without the reactor becoming sub-critical by simply turning off the cyclotron. The ADR operates between 3-8MPa and can reach temperatures up to 500°C [14].

Fig. 1.5.1 An Accelerator Driven System equipped with a long-lived fission product transmutation (incineration) facility. A high power proton accelerator is coupled to the subcritical assembly producing spallation neutrons in the lead target which sustain the chain reaction in the core. The fuel rods are made of mixed oxides of thorium and U-233 (or plutonium and minor actinides from the nuclear waste of the conventional reactors). M-material in the diagram refers to the environment that acts as neutron and heat storage medium as well as neutron moderator. (Uranium Mining, Processing and Nuclear Energy Review)

Note: Although the diagram depicts lead in the core, this may be interchanged with other fuels such as Thorium [15].

1.6- Fast-Neutron Reactors (FNR)

Last but not least is the fast-neutron reactor. This reactor is said to be highly compatible with Thorium and uses fast neutrons to sustain a fission reaction chain. This reactor eliminates a lot of fuels radiotoxicity, in comparison to all water reactors. It does this by transmuting the nuclear waste that would be generally unusable and gets even more energy out of them, thus reducing the levels of actinides which in turn reduces the radiotoxicity. These reactors generally use liquid metal coolant such as Sodium-Potassium alloy. Water is an ineffective coolant in this reactor as it acts as a neutron moderator, which hinders the reactors capabilities.

2. Methodology

This Meta study hopes to distinguish which reactor would be the most beneficial to further research and develop by comparing the effect of temperature, pressure, volume and power flux density on the plants thermal efficiency.

2.1-Data collection phase

In this phase the following steps were undertaken to find information and data. This includes setting search restrictions, including: Restricting results to the last 30 years and reactor design to full thorium fuels or uranium/thorium combination reactors. We used the scientific data-bases ‘Access Science’, ‘science direct’ and ‘Proquest Science and Technology’ for the majority of our searches. We attempted to focus on the keywords that were outlined at the start of our meta-study. We also wanted to clarify that our interpretation of a thorium nuclear reactor is any reactor which either fully or partially utilises Thorium in conjunction with another fuel or by itself.

2.2-Data processing phase

We decided to focus on how the thermodynamics of the system effected both the reactors efficiency and its power flux density. Efficiencies were obtained from specific reactors, whereas calculation of power flux density was calculated by using collected data on volume and power output and dividing them. These data points were compared to both temperature, pressure and against one another. Microsoft excel was used to produce the tables and graphs.

2.3-Data calculation phase

| Core power flux calculated using |  |

| Volume for spherical fuel calculated using |  |

| Liquid fuel data was obtained from papers | |

| Core volume (if cylinder) | πr2h |

3. Results

3.1-Efficiency comparisons

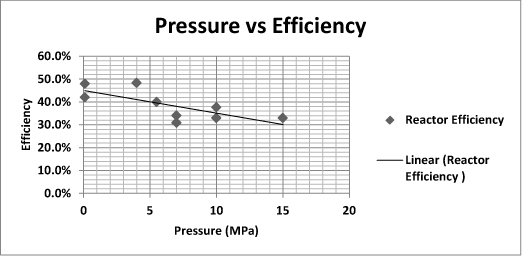

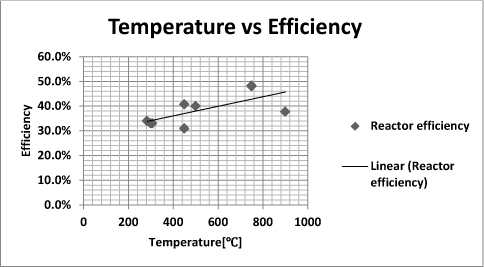

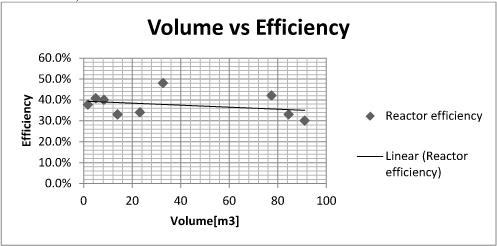

Figure 3.1.1

(All data from table 1)

The above graph shows a slight negative linear relationship between the volume and efficiency of a reactor. We do acknowledge however there are few data points and future research may be done on this relationship.

There appears to be a strong linear relationship between the pressure and efficiency of the reactors. Considering numerous reactors, we have noticed a trend that higher pressures of a reactor correlate to reduced efficiencies. Plants such as the Molten Salt Reactor achieved some of the highest efficiencies and did so at atmospheric pressure, where the least efficient plants run on 10MPa.

A strong relationship between higher temperatures and higher efficiencies can be seen in the above graph. Low temperature plants such as the BWR are seen with low efficiencies and High temperature plants such as the HTGR are seen with much higher efficiencies.

3.2-Tabulated data

| Place | Reactor | Temp (c) | Pressure (MPa) | Efficiency | Thermal output (MW) | Cycle |

| 1 | PMR | 785 | 4.8 | 48.30% | 837 | Brayton |

| 2 | MSR | 750 | 0.1 | 48.0% | 3000 | Brayton |

| 3 | FNR | 450 | 0.1 | 42% | 1000 | Brayton |

| 4 | ADR | 500 | 5.5 | 40.0% | 250 | Brayton |

| 5 | PBR | 900 | 10 | 40.0% | 1250 | Brayton |

| 6 | BWR | 283.5 | 7 | 34.0% | 3580 | Rankine |

| 7 | PWR | 307 | 15 | 33.0% | 3580 | Rankine |

| 8 | AHWR | 450 | 7 | 30.9% | 920 | Rankine |

| 9 | PHWR | 300 | 10 | 30.0% | 930 | Rankine |

| Ranking | Reactor | Core power flux | Efficiency | Source |

| 1 | FNR | 601.79 | 42 | [1] |

| 2 | PWR | 214.59 | 34 | [1] |

| 3 | BWR | 129.25 | 33 | [1] |

| 4 | MSR | 91.83 | 48 | [2] |

| 5 | ADR | 47.8 | 40 | [3] |

| 6 | PMR | 21.00 | 38 | [1] |

| 7 | PHWR | 11 | 33 | [4] |

| 8 | AHWR | 10.10 | 30.9 | [5] |

| 9 | PBR | 5.61 | 37.7 | [6] |

4. Discussion

4.1-Light water Reactors

The light water reactors, which encompass both the PWR and BWR were found to have efficiencies of around 34% (BWR) and 33% (PWR). These two reactors operate at temperatures around 300°C with the BWR using pressures of 7MPa and PWR using 15MPa, the highest pressure out of all the reactors we investigated. These reactors most commonly used the Rankine thermodynamic cycle and it was found that thorium when combined with Uranium is applicable for use with these reactors and can provide economic and safety benefits, but does not produce any thermodynamic benefit [3]. Light water reactors are the most widely used reactors for electricity production across the world. This is largely attributed to their simplicity in design and large understanding and operational experience. Despite this though they have numerous drawbacks such as high amounts of nuclear waste, low efficiency and safety concerns surrounding meltdowns. However a redeeming quality which we calculated was a high power flux. The PWR and BWR respectively were calculated to have Power flux densities of 214MW/m3 and 129MW/m3 respectively, some of the highest we calculated.

4.2-Pressurized Heavy Water Reactors (PHWR)

The PHWR has the potential to deliver up to 930 MW [16] and is able to sustain a thermal efficiency up to 30%. This is due to maximising the benefits of the ‘Rankine’ [17] thermodynamic cycle and also due to the neutron economy of heavy water. These benefits are a result from the pressurised heavy water system. The limiting factors in the thermal efficiency include ‘ballooning’ [18] to the pipes due to high pressure and high temperature; this ballooning is the effect of the volume expansion due to high pressure and the deformation of the pipes due to heat. This makes the pipe’s metal stretch and in the end creates a ballooning effect. Another limiting factor is the limited knowledge of materials to increase the neutron economy high, as thorium needs a higher neutron economy to be more efficient due to a high conversion ratio of 0.95.

Although there seems to be a potential for this reactor, there is a complete lack of research in enriching of fuels and the materials used in the main heat transfer pipes. The heat transfer pipes undergo a ‘ballooning’, which in end, throws out the ‘Rankine’ thermodynamic cycle due to the change in volume, which leads to a loss in efficiency. Before this reactor can be considered in the future of energy science, research on the materials to raise the neutron economy [19] and materials in the heat transfer piping must take place in order for the PHWR to be considered. The power flux was also calculated and we obtained a value of 11MW/m3. This is a relatively low value in comparison to the light water reactors, the low value is attributed to the lower thermal output of the plant.

4.3-Advanced Heavy Water Reactors (AHWR)

This reactor is a more innovative reactor, however they are still in construction. The unique feature of these reactors is that they have been designed with the intension to run completely on thorium. The main difference between the AHWR and the PHWR is that the AHWR uses heavy water as the moderator, and light water as the coolant. The specifications seem very closely related to the PHWR, mainly differing in the pressure, where the AHWR runs at around 7MPa, with a moderator volume of 117 m3 and the efficiency is found to be 30.9% [20]. The average fuel temperature of this reactor is 450°C [21]. Calculations of power flux were relatively low at 10.10MW/m3. This is due to the large volume in respect to power. So although the AHWR specifications are much lower than that of other reactors such as the molten salt reactors, this reactor is the most promising for an economic switch from uranium to thorium.

4.4-High Temperature Gas cooled Reactors (PMR/PBR)

Although we found more efficient reactors than the HTGR this does not rule it out as a good candidate for our future energy needs, both HTGR and PBR use the Brayton thermodynamic cycle. The PMR had high efficiency’s up to 48.3% although most reactors are much lower seen in table 3. The main drawback of this form of reactor is its lower thermal output, being in the range of 837 MWTh. Although most reactors presently have much lower outputs as seen in table 2 below. What most HTGR’s lack in thermal output, they make up for in high potential in secondary applications. One such report outlines that using the coolant to make Hydrogen can drive up efficiencies quite highly [8]. Both of these reactor types are well suited to use with thorium due to the high operational temperatures as thorium has a high thermal stability [7].

The pebble bed reactor although slightly less inefficient and with lower outputs than its PMR counterpart, still has many benefits relating to the pebble based fuel which can be put into and out of the reactor while operating. A study by S. Sen et al [10] found that running the PBR at 900°C and 10MPa achieved the highest thermal efficiencies for a PBR of 40%. The pebble bed reactor however, due to the 2008 report about its safety concerns, as mentioned in the introduction, has resulted in the lack of research and study in this field. Needless to say, if the obstacles can be overcome, based on the thermodynamics alone both these reactors should be highly viable thorium reactors which can be used to supply our energy needs. The only active HTGR project is the HTR-PM in China [22]. As seen in the table 3 below the power flux densities were particularly low for all HTGR’s. We believe this is attributed to large volumes in respect to the output. On average the Power flux density for HTGRs was 3.36 MW/m3.

| Name | Temperature | Pressure | Volume | Power flux | Output | Efficiency | Source |

| FSV(PMR) | 785 | 4.8 | 370 | 2.62 | 837 | 39.50% | 1 |

| (PBR) | / | / | 1.78 | 5.62 | 10 | 37.70% | 2 |

| HTR-PM (PMR) | 750 | 7 | 77.75 | 3.22 | 250 | 42% | 3 |

| GT-MHR (PMR) | 850 | 7 | / | / | 600 | 48% | 4 |

| HTR-10 (PBR) | 700 | 3 | 5.01 | 2.00 | 10 | / | 5 |

/ Indicates information that we were unable to obtain. Full list of references in bibliography.

4.5-Molten salt reactors

The most distinctive feature of the molten salt reactor is the core. A prominent design for a core is that the core is described to be a cylinder with the diameter the same size as the height, and to be filled with an abundance of molten salt with no solid moderator material. Instead of the traditional method of nuclear fission, the molten salt acts as a coolant, fuel and a moderator.

Figure 4.5 Diagram of MSR [23]

From studies in the past the most fuel economic molten salt mixture is comprised of LiF(77.5%)-ThF4(20%)-UF4(2.5%).[24] When the compositions for the molten salt were being researched, the eutectic point of the salt was always the goal so the salt will be a molten liquid at lower temperatures.[25] The main benefit of a molten salt fuel is the great heat transfer abilities as well as high fission efficiencies with large power outputs, such as the thermal power output of 3 GW [26]. Depending on the temperature, the molten salt reactors thermal efficiency varies. For instance at 750°C the thermal efficiency is 48%, while at 1000°C, the efficiency is 59% [27]. However, in this study, the 750°C reactor is being observed due to fact that they are commonly used and implemented.

The main thermodynamic cycle in a molten salt reactor is the Brayton cycle [28]. The Brayton cycle is a common thermodynamic cycle used in newer nuclear fission systems. This cycle is selected for nuclear fission systems that operate at higher temperatures, therefore allowing higher cycle efficiencies.

In terms of power flux density, the MSR did quite well with a value of 91.83. This is ranked 4th overall and this value tied together with high output and high efficiency makes it an ideal candidate for future energy needs.

4.6-Fast-Neutron Reactor (FNR)

The fast-neutron reactor has great potential in terms of use with thorium. It has a reasonable efficiency for a fission reactor sitting at 42%. Although this reactor was envisioned primarily for use with uranium compounds, there is an alternate road opening up for this reactor to be used with thorium. With the implementation of thorium fuels, the sought-after idea of limiting radiotoxicity from the reactor has now become a reachable goal.

The specifications of a typical FR commercially used are 1000 MW thermal output using sodium as a coolant [29]. Since the 1950’s there have been many attempts to improve the output power of the fast-neutron reactors, however the solution was found in the idea of a molten salt or molten metal reactor. The thermal properties of sodium in the core acting as a coolant are now ideal. Since the boiling point of sodium is roughly 893oC, this makes a good coolant for this reactor [30]. Sodium has been compared to H2 as a coolant, but the thermal transfer efficiency is much higher with the use of sodium.

In comparison to a PWR, the breeder reactors have a much higher power transfer density. The reason for this is that the breeder reactors have a smaller core being around 5.02m3. Due to the higher thermal power in a more condensed space, the thermodynamics increase in complexity that causes slight changes to the output power. The high temperature creates an expansion amongst the fuel/coolant and from this there is a decrease in the number of fissile nuclei per unit area, which in turn will reduce the reactor output [30]. The FNR had the highest power flux density out of all the reactors in this study. By our calculations it obtained a power flux of 601MW/m3.

4.7-Accelerator Driven Reactors

Lastly we have the Accelerator Driven Reactors. They are still quite experimental and need much more research until they are fully equipped to meet out energy needs. They were found to operate at temperatures as high as 500 °C and pressures in the range of 3-8MPa [31]. Overall this reactor was found to be quite efficient ranking 4th out of all the reactors we studied. For an experimental reactor, there is a large amount of potential in this field. The main focus of this reactor is improving how the Proton beam is to react with the target in the core. One other area that may need extra research is the cyclotron itself, which only produces around one neutron per 25 MeV produced by the proton beam [31]. This can be improved by increasing the power, however it takes away from the overall power produced by the core. The core volume was calculated by making the assumption of a cylindrical core. Using the data from A. Fokau [32]. The volume was calculated to be 8.369m3 with a power flux of 47.80 MW/m3, ranking 5th out of all the reactors we calculated values for.

5. Conclusion

The area of energy production from nuclear fission is a dynamic area. There are many variables to account for when looking for the implementation of a reactor. These variables include economics, safety and practicalities. However this study is focused on the thermodynamics of the individual reactor types, found by the works of other researchers. In this study it was found that pressure and temperature play key roles in the efficiency of all nuclear reactors. The data collected indicates, that an increase of pressure and decrease of temperature would reduce plant efficiencies. An excellent example of this is seen in the molten salt reactors with efficiencies being highly temperature dependent and ranging from 48%-60% between the ranges of 700 and 1000 degrees. Another factor which still needs further investigation is the effect of core volume on efficiency. We found a trend downwards in efficiency as the volume increased. However, due to the number of parameters and the few reactors involved in the data points, we believe it beneficial to revisit this topic more specifically in the future. One last area of investigation was the effect of power flux density on plant efficiency. This study found no direct link between the two variables.

The secondary component of this meta-study hoped to highlight which reactor obtained the highest thermal efficiencies based on thermodynamic data, while still providing adequate energy. We found that Light water reactors, despite their high output, are very inefficient.

Despite this, Light water reactors had some of the highest power flux densities, with only the fast neutron reactor having higher results. The Heavy water reactors have similarly low efficiencies but slightly lower outputs and power flux densities. The advantage here however, is heavy water reactors in the form of the AHWR are more suitable for thorium, whereas Thorium is less ideal for light water reactors. Molten Salt reactors appear to have the most attractive characteristics for future development and study, it is highly suitable for thorium fuels and has high efficiency and moderate power flux densities, while not compromising a high thermal output. HTGRs are another area of interest which should have further research and attention, not only for energy production but for secondary applications as discussed in this study. HTGRs are highly suitable for Thorium and have relatively high efficiencies, with a lower thermal output. However the power flux density for these reactors are very low. Lastly, the still very experimental Accelerator Driven reactors appear to have many beneficial features, such as moderate power flux densities and relatively high efficiencies. Despite this its thermal output is still quite low and dependent on better cyclotron technology to create the proton beam strong enough to start the fission process.

6. Acknowledgments

We would like to acknowledge Dr Jurgen Schulte who gave guidance for this meta-study.

7. Notes

*Efficiencies are different to Table 1 efficiencies due to different reactor specific calculations. The data for Table 2 needed both volume and efficiency, hence some reactors from Table 1 were not applicable.

8. References and Notes

[1] World-nuclear.org, (2015). Thorium. [online] Available at: http://www.world-nuclear.org/info/Current-and-Future-Generation/Thorium/ (Accessed 15 Mar. 2015).

[2] R.A. Chaplin, Department of Chemical Engineering, University of New Brunswick, Canada, NUCLEAR REACTOR HEAT REMOVAL.

[3] Victoria A. Schopflin, Faculty of Rensselaer Polytechnic Institute, The Use of Thorium Uranium Dioxide in Current Pressurized Water Reactors.

[4] Rahn, Frank J. Nuclear Power Division, Electric Power Research Institute, Palo Alto, California, Nuclear reactor.

[5] R.A. Chaplin. Pressurized Heavy Water Reactors. Nuclear Energy Materials and Reactors

[6] R.K. Sinha, A. Kakodkar. Design and development of the AHWR—the Indian thorium fuelled innovative nuclear reactor. Nuclear Engineering and Design, Volume 236, Issues 7–8, April 2006, p 683–700.

[7] David A. Rodriguez Sanchez, Faculty of Applied Physics, Delft University of Technology, Netherlands, Safety analysis of a thorium-fueled High Temperature Gas-cooled Reactor.

[8] Po-Jui Li, Tzu-Chen Hung, Bau-Shei Pei, Jaw-Ren Lin, Ching-Chang Chieng, Ge-Ping Yu. A thermodynamic analysis of high temperature gas-cooled reactors for optimal waste heat recovery and hydrogen production. Applied Energy, Volume 99 (2012) Pages 183–191

[9] Very High Temperature Reactor by US Department of Energy Nuclear Energy Research Advisory Committee - http://www.ne.doe.gov/genIV/documents/gen_iv_roadmap.pdf. Licensed under Public Domain via Wikimedia Commons - http://commons.wikimedia.org/wiki/File:Very_High_Temperature_Reactor.svg#/media/File:Very High Temperature Reactor.svg (Accessed on 2/5/15).

[10] S. Sen, O.K. Kadiroglu, Thermodynamic analysis of PBMR plant, in: Proceedings of the 1st International Topical Meeting on HTR Technology, Petten, NL, 2002.

[11] Rainer Moormann (1 April 2009). PBR safety revisited. Nuclear Engineering International. Retrieved 2009-04-02.

[12] David A. Rodriguez Sanchez. Safety analysis of a thorium-fueled HighTemperature Gas-cooled Reactor. Faculty of Applied Physics, Delft University of Technology

[13] X. Doligez, D. Heuer, E. Merle-Lucotte, M. Allibert, V. Ghetta. Coupled study of the Molten Salt Fast Reactor core physics and its associated reprocessing unit. Annals of Nuclear Energy, Volume 64, February 2014, Pages 430–440.

[14] M. Piera, C. Corrochano, A. Abamades, J. Munoz-Anton. Conceptual design of a gas-cooled accelerator-driven reactor with very fast spectrum. Progress in Nuclear Energy, Volume 78, January 2015, Pages 361–371

[15] Accelerator Driven Nuclear Energy: Available online: http://www.world-nuclear.org/info/Current-and-Future-Generation/Accelerator-driven-Nuclear-energy/ (Accessed on 10/5/15)

[16] Other Designs of Nuclear Power Stations, http://nucleus.iaea.org/sites/graphiteknowledgebase/wiki/Guide_to_Graphite/Other%20Designs%20of%20Nuclear%20Power%20Stations.aspx, Andreas Poullikkas, An overview of future sustainable nuclear power reactors, ENERGY AND ENVIRONMENT

[17] Andreas Poullikkas. An overview of future sustainable nuclear power reactors. ENERGY AND ENVIRONMENT.

[18] Gopal Nandana, P. Majumdar, P.K. Sahooa,*, Ravi Kumar, B. Chatterjee, D. Mukhopadhyay, H.G. Lele. Study of ballooning of a completely voided pressure tube of Indian PHWR under heat up condition. Nuclear Engineering and Design 243 (2012) 301–310

[19] Torgerson, David F, CANDU Reactor. The Science Authority,

[20] https://aris.iaea.org/sites/.%5CPDF%5CAHWR.pdf, ADVANCED HEAVY WATER REACTOR (AHWR), BARC (India).

[21] A.P. Deokulea, A.K. Vishnoi, K. Umasankari, D.K. Chandraker, P.K. Vijayan, S. Ganesan. Design of 33 pin annular fuel rod cluster for Advanced Heavy Water Reactor. Nuclear Engineering and Design, Volume 256, March 2013, Pages 94–101

[22] Small nuclear power reactors: Available online: http://www.world-nuclear.org/info/nuclear-fuel-cycle/power-reactors/small-nuclear-power-reactors/ (Accessed 19/5/15)

[23] http://www.ne.doe.gov/genIV/documents/gen_iv_roadmap.pdf, US Department of Energy Nuclear Energy Research Advisory Committee, 2002

[24] M.K.M. Ho, G. H. Yeoh, and G. Braoudakis Molten salt reactors, Materials and processes for energy: communicating current research and technological developments (A. Méndez-Vilas, Ed.)

[25] Degtyarev, A., Myasnikov, A. and Ponomarev, L. (2014). Molten salt fast reactor with U–Pu fuel cycle. Progress in Nuclear Energy.

[26] M.K.M. Ho, G. H. Yeoh, and G. Braoudakis Molten salt reactors, Materials and processes for energy: communicating current research and technological developments (A. Méndez-Vilas, Ed.)

[27] World-nuclear.org, (2015). Molten Salt Reactors. [online] Available at: http://www.world-nuclear.org/info/Current-and-Future-Generation/Molten-Salt-Reactors/ [Accessed 10 May 2015].

[28] Doligez, X., Heuer, D., Merle-Lucotte, E., Allibert, M. and Ghetta, V. (2014). Coupled study of the Molten Salt Fast Reactor core physics and its associated reprocessing unit. Annals of Nuclear Energy, 64, pp.430-440.

[29] Lindley, B., Fiorina, C., Franceschini, F., Lahoda, E. and Parks, G. (2014). Thorium breeder and burner fuel cycles in reduced-moderation LWRs compared to fast reactors. Progress in Nuclear Energy, 77, pp.107-123.

[30] Robert Dautray, Comptes Rendus Mecanique, The long-term future for civilian nuclear power generation in France: The case for breeder reactors Breeder reactors: The physical and physical chemistry parameters, associate material thermodynamics and mechanical engineering: Novelties and issues

[31] World-nuclear.org, (2015). WNA Information Library. [online] Available at: http://www.world-nuclear.org/info/Current-and-Future-Generation/Accelerator-driven-Nuclear-energy/ [Accessed 23 May 2015].

[32] A. Fokau, “Accelerator-Driven Systems: Source Efficiency and Reactivity Determination”, Stockholm, Sweden 2010

Table References

Table 1.

References are in order as they appear in the table

[1] D. A. Copinger, D. L. Moses 2004, Fort Saint Vrain Gas Cooled Reactor Operational Experience, NUREG/CR-6839ORNL/TM-2003/223, Oak Ridge National Laboratory, Oak Ridge, accessed on 18/5/15, <www.nrc.gov/reading-rm/doc-collections/nuregs/.../cr6839/cr6839.pdf >

[2] Aufiero, M., Brovchenko, M., Cammi, A., Clifford, I., Geoffroy, O., Heuer, D., Laureau, A., Losa, M., Luzzi, L., Merle-Lucotte, E., Ricotti, M. and Rouch, H. (2014). Calculating the effective delayed neutron fraction in the Molten Salt Fast Reactor: Analytical, deterministic and Monte Carlo approaches. Annals of Nuclear Energy, 65, pp.78-90.

[3] Lindley, B., Fiorina, C., Franceschini, F., Lahoda, E. and Parks, G. (2014). Thorium breeder and burner fuel cycles in reduced-moderation LWRs compared to fast reactors. Progress in Nuclear Energy, 77, pp.107-123.

[4] Piera, M., Corrochano, C., Abánades, A. and Muñoz-Antón, J. (2015). Conceptual design of a gas-cooled accelerator-driven reactor with very fast spectrum. Progress in Nuclear Energy, 78, pp.361-371.

[5] Herranz, L., Linares, J. and Moratilla, B. (2009). Power cycle assessment of nuclear high temperature gas-cooled reactors. Applied Thermal Engineering, 29(8-9), pp.1759-1765. S. Sen, O.K. Kadiroglu, Thermodynamic analysis of PBMR plant, in: Proceedings of the 1st International Topical Meeting on HTR Technology, Petten, NL, 2002.

[6] M. Ragheb, “NUCLEAR REACTOR CONCEPTS AND THERMODYNAMIC CYCLES”

[7] R.A. Chaplin, “NUCLEAR REACTOR HEAT REMOVAL”, Department of Chemical Engineering, University of New Brunswick, Canada

[8] ADVANCED HEAVY WATER REACTOR (AHWR), BARC (India), https://aris.iaea.org/sites/..%5CPDF%5CAHWR.pdf

[9] Other Designs of Nuclear Power Stations, http://nucleus.iaea.org/sites/graphiteknowledgebase/wiki/Guide_to_Graphite/Other%20Designs%20of%20Nuclear%20Power%20Stations.aspx

Table 2.

[1] M. Ragheb, “NUCLEAR REACTOR CONCEPTS AND THERMODYNAMIC CYCLES”

[2] Xiao, Yao et al. ‘Numerical Analysis For A Molten Salt Reactor In The Presence Of Localized Perturbations’. Progress in Nuclear Energy 60 (2012): 61-72. Web.

[3] A. Fokau, “Accelerator-Driven Systems: Source Efficiency and Reactivity Determination”, Stockholm, Sweden 2010

[4] Unknown Author, Available online: <https://www.facebook.com/l.php?u=https%3A%2F%2Fcanteach.candu.org%2FContent%2520Library%2F19980101.pdf&h=9AQF1bIjd > accessed 20/5/5

[5] ADVANCED HEAVY WATER REACTOR (AHWR), BARC (India), https://aris.iaea.org/sites/..%5CPDF%5CAHWR.pdf

[6] Şeker, Volkan, and Üner Çolak. ‘HTR-10 Full Core First Criticality Analysis With MCNP’. Nuclear Engineering and Design 222.2-3 (2003): 263-270. Web.

Table 3.

[1] D. A. Copinger, D. L. Moses 2004, Fort Saint Vrain Gas Cooled Reactor Operational Experience, NUREG/CR-6839ORNL/TM-2003/223, Oak Ridge National Laboratory, Oak Ridge, accessed on 18/5/15, <www.nrc.gov/reading-rm/doc-collections/nuregs/.../cr6839/cr6839.pdf >

[2] M.Ragheb 2015, Nuclear Reactor Concepts and Thermodynamic Cycles, accessed online: 18/5/15, http://www.google.com.au/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0CCIQFjAA&url=http%3A%2F%2Fmragheb.com%2FNPRE%2520402%2520ME%2520405%2520Nuclear%2520Power%2520Engineering%2FNuclear%2520Reactors%2520Concepts%2520and%2520Thermodynamic%2520Cycles.pdf&ei=QipbVfr8C8XU8gXj7YCYAg&usg=AFQjCNEpAZCj6KDxWpExCJhvrXi_y5MPug

[3] Zhang, Z., Wu, Z., Wang, D., Xu, Y., Sun, Y., Li, F. and Dong Y. (2009), Current status and technical description of Chinese 2×250MWth HTR-PM demonstration plant. Nuclear Engineering and Design, 239(7), pp.1212-1219.

[4] C.B. Baxi, E. Perez, A. Shenoy, V.I. Kostin, N.G. Kodochigov, A.V. Vasyaev, S.E. Belov, and V.F. Golovko, General Atomics Report A25381, Evolution of the Power Conversion Unit Design of the GT-MHR

[5] Şeker, V. and Çolak, Ü. (2003). HTR-10 full core first criticality analysis with MCNP. Nuclear Engineering and Design, 222(2-3), pp.263-270.