Construction Economics and Building

Vol. 24, No. 4/5

December 2024

RESEARCH ARTICLE

Impact of Modular Integrated Construction Indicators on Sustainable Performance Metrics in Nigeria

Akinsanmi Sheriff Akindeinde1,*, Joseph Aderemi Akinola2, Lekan Damilola Ojo3, Okechukwu Augustine Kenechukwu4,

1 Federal University of Technology, Akure, Ondo State, Nigeria, qssanmi@gmail.com

2 Federal University of Technology, Akure, Ondo State, Nigeria, jaakinola@futa.edu.ng

3 The Hong Kong Polytechnic University, Hong Kong, lekan-damilola.ojo@polyu.edu.hk

4 Federal University of Technology, Akure, Ondo State, Nigeria, okechukwuaugustine95@gmail.com

Corresponding author: Akinsanmi Sheriff Akindeinde, Federal University of Technology, Akure, qssanmi@gmail.com

DOI: https://doi.org/10.5130/AJCEB.v24i4/5.8865

Article History: Received 14/10/2023; Revised 19/09/2024; Accepted 28/09/2024; Published 23/12/2024

Citation: Akindeinde, A. S., Akinola, J. A., Ojo, L. D., Kenechukwu, O. A. 2024. Impact of Modular Integrated Construction Indicators on Sustainable Performance Metrics in Nigeria. Construction Economics and Building, 24:4/5, 81–97. https://doi.org/10.5130/AJCEB.v24i4/5.8865

Abstract

The Nigerian construction industry is faced with environmental degradation, economic and social-related challenges, in which Modular Integrated Construction (MiC) could be regarded as practical solution. Sadly, construction professionals and stakeholders are reluctant to adopt this innovative approach in developing countries like Nigeria. This informs the necessity to investigate the relationships between MiC indicators and performance metrics with a survey of professionals with practical experience in the use of MiC in executing infrastructure in Lagos and Abuja, Nigeria. The data retrieved from the respondents were analysed using both descriptive and inferential statistics. Pearson correlation was used to determine the relationships between MiC indicators and performance in this study. The results of the analysis revealed that both procedural and internal MiC indicators are significant to enhancing economic, environmental, and social performance. In addition, it has been demonstrated that the impact of MiC is extremely beneficial in all construction ramifications for sustainable practice. Based on the findings of this study, it is suggested that massive awareness campaigns regarding the necessity of using technology in construction activities be launched among professionals and stakeholders in the construction industry to enhance the use of MiC in the Nigerian construction industry.

Keywords

Indicators; Modular Integrated Construction; Nigerian Construction; Sustainability; Performance

Introduction

The construction industry remains an indispensable contributor to other sectors through the provision of infrastructure to meet socioeconomic and national goals such as shelter provision; employment, and so on (Ade-Ojo, et al., 2016). Thus, it is highly necessary to effectively manage, improve, and drive the construction sector to ensure its maximum rewards to society. The awareness of environmental, social, and economic problems associated with conventional construction pattern has driven business leaders across nations to embrace practices that are more sustainable (Murali and Sambath, 2020) to enhance efficiency, reduce lifecycle financial costs, minimize all kinds of pollutions, and so on. Through modular construction and prefabrication which is described as manufacturing of infrastructure components in a controlled environment, transported, positioned, and assembled at the construction site is considered as a suitable alternative to traditional pattern of executing construction projects in the last few decades (Jiang, et al., 2019; Murali and Sambath, 2020; Zhang, et al., 2018).

Conventional on-site construction methods have long been criticized for low productivity, poor quality, safety records, long construction time, and large quantities of waste in the industry (Chen, Okudan and Riley, 2010). In addition, traditional construction methods also contribute to energy consumption and environmental pollution (Jiang, et al., 2019). In fact, environmental, economic, and social concerns have led construction stakeholders to adopt new practices that is aimed at reducing resource consumption, energy use, and gas emissions (Murali and Sambath, 2020). Furthermore, balancing the impacts of building these three dimensions (i.e., environmental, economic, and social) in the entire lifecycle is a key factor towards sustainable projects. Indicators and their performance are highly dependent on the environmental, social, and economic contexts of their use. This problem serves as a motivation for most researchers to develop sustainability assessment systems (Tupenaite, et al., 2017). Modular integrated construction (MiC) has attracted scholarly debates and attention in the recent discussions in the construction industry, particularly in developing countries with limited fund and professional expertise (Wuni and Shen, 2021). Decisions to use MiC are still largely based on anecdotal evidence or simply cost-based evaluation when comparing various construction methods (Chen, Okudan and Riley, 2010). However, understanding the long run impact of MiC indicators on performance metrics could make construction stakeholders to make pragmatic move to embrace MiC. Hence, this study empirically investigated the relationships between the indicators and performance metrics on MiC projects.

Literature review

Overview of MiC

MiC is often referred to as the planning, design, manufacturing, fabrication, and preassembling of various building elements, components, and modules in an enclosed environment commonly referred to as “factory production” before their final installation on site to support rapid permanent structure (Goodier and Gibb, 2007). MiC is a procedure in which a building is executed off-site under regulated factory settings, with the same materials and stipulated requirements as traditionally built facilities (Yang, Pan and Pan, 2017). The MiC techniques was used about 3000 years ago when King Solomon built the temple of God in Jerusalem. As revealed in the Bible, the sanctuary was constructed with prefabricated stones before being brought to the temple site such that there was neither sledge nor hatchet or any device of iron heard in the house (1 Kings 6:7, New international version). MiC can also occur concurrently with site operations, allowing projects to be finished in 30-50% of the period of traditional construction. Aside from faster completion time and quality management, it also provides various other advantages to owners. Wuni and Shen (2021) opined that because each module has been designed to survive the rigours of transit and craning into foundations, modular structures are often stronger structurally than site-built construction. Site disturbance, less noise pollution and traffic congestion on MiC projects also culminate in improving overall safety and security (Lawson, 2008).

Modular building is intrinsically a natural match as owners and designers investigate its advantages and search for more environmentally friendly designs. In a regulated setting, waste is reduced through prevention upstream rather than transmission downstream. This naturally encourages sustainability, better quality management throughout the building process and substantially less activity and disruption on the job site (Yang, Pan and Pan, 2017). Additionally, the danger of inclement weather and delays can be reduced drastically, while hastening occupancy and return on investment simultaneously because considerable percentage (between 60-90%) of the projects are produced in the factory (Wuni and Shen, 2022). MiC can also be provided with Mechanical, Electrical and Plumbing (MEP), fixtures, and interior finishes in less time, with less waste, and with superior quality control. MiC may operate with degrees of conceptualization and physical sophistication that will surpass all expectations and challenge their site-built competitors, benefiting architects, developers, and owners alike (Egege, 2018).

MiC has seen successful implementation in various countries and region worldwide. In the United States, MiC is prevalent in residential and commercial projects, offering cost-effective and efficient building solutions (Abdelmaged and Zayed, 2020). European countries leverage MiC for housing and infrastructure developments, emphasizing its sustainability and rapid construction benefits (Wuni and Chen, 2022). Additionally, countries like China have extensively adopted MiC for high-rise buildings and affordable housing initiatives (Pan and Hon, 2020). These instances showcase the versatility and potential advantages of MiC, including reduced construction time, minimized environmental impact, and enhanced affordability, which could inform its successful implementation in the Nigerian context.

MiC indicators

Sustainability is an ambiguous and multifarious concept (Zhou, Rybski and Kropo, 2013), and indicators is also a general approach to measuring sustainability performance in the construction sector. Indicators condense large and complex information into recognisable facts and provide a basis for making further decisions. Zhang, et al. (2021) described a sustainability indicator as a measurable variable (quantitative or qualitative) that defines a preferable outcome geared towards attaining sustainability goals. The indicators cut across the construction cycle and addresses issues related to waste management, energy use, water quality and consumption, biodiversity, air quality, land contamination, light pollution, noise emissions, and environmental management (Yu, Xu and Lu, 2018). This approach holds promise for Nigeria’s development, particularly given the country’s vast size, diverse socio-economic landscape, and infrastructure deficits (Akinradewo, et al., 2023; Bello, et al., 2023). The barriers faced with MiC in developing countries like Ghana (Wuni and Shen, 2021), Egypt (Ali, et al., 2023), and South Africa (Dupwa, 2017) signals potential for growth and innovation in developing countries.

The integration of sustainability indicators in MiC offers a pathway for Nigeria and Africa at large to achieve sustainable development goals and meeting the infrastructure demand (Bah, Faye and Geh, 2018). With the immense volume of wastes and energy generated and/or dissipated by conventional construction methods, the MiC method is a viable means to reverse this trend and set the tone for a more sustainable approach to construction especially on a large scale (Humphrey, 2018). Also, Rahimian, et al. (2017) stated explicitly that MiC has been successful in reducing waste generation of typical construction projects by 70% to 90%. This assertion is a very strong indicator that MiC contributes to the sanity of most construction sites in the country (Humphrey, 2018). Since the entire process of construction generates several types of wastes and pollution, off-site techniques, when implemented to the full, tend to reverse the trend and ensure cleaner and more effective construction process (Yu, Xu and Lu, 2018).

With the use of MiC, there are a lot of cost savings, time, materials, and processes (Boafo, Kim and Kim, 2016). Also, sustainable construction methodology to preserve the ecosystem is also put into consideration in its usage (Khan, Yu and Liu, 2021). On the other hand, some of the indicators that define MiC are found to be in tandem with the performance metrics of its usage in construction activities. The intrinsic features in the use of MiC come to play in the actual construction given the fact that most construction projects in which they are used achieve the desired quality and satisfy the requisite criteria for sustainability (Kamali and Hewage, 2015). It is therefore imperative to say that MiC is very crucial beneficial to the construction sphere as it serves a huge boost in creating a paradigm shift away from the traditional construction system.

The cost factor of the variables for the indicators for MiC adoption consideration is so important that it is sometimes at the forefront of the considerations (Zakaria, et al., 2018). This is due to the nature of the construction industry in engulfing huge amount of material, machinery and technological resources amongst others, making it a capital-intensive sector. The cost intensive nature of the construction sector sets it aside as a resource-consuming sector since all the processes involves huge cost commitments. The study recognises these factors to be basically key in empowering construction professionals to consider MiC’s performance. However, Hong, et al. (2016) opposes the findings of this study by stating that the total cost of MiC adoption is very much higher than conventional construction methods. They stated that modules and production processes for construction components in MiC makes it very much discouraging for most clients and professionals to utilize it for their projects.

This factor is so much concerned with those aspects of consideration for MiC’s performance that makes it easier for its utilization in the development (Murali and Sambath, 2020). Variables such as logistics and travel congestion, community disturbance and formwork consumption are all directed towards this factor. Logistics on the other hand, is very vital to MiC’s performance, for instance, the transportation of the modules to the site for fixing demonstrates it importance. According to Murali and Sambath, (2020), the study’s assertion that MiC is extremely beneficial for logistics purposes such as traffic and transportation of modules to site. In avoiding project delays or excess inventory, module production rates are dependent on module transportation and installation speeds (Hussein, et al., 2022). In their example study, Yang, Pan and Pan (2022) said that manufacturing speed and modification are crucial to the offsite logistics of modular building. Invariably, it implies that this factor is crucial in the persuasion of construction professionals to MiC’s performance for their projects. Furthermore, MiC is capable of minimizing the level of unnecessary travel (even relocations) by workers to construction sites as well as on-site patrolling activities, since every party produces the components in their own premises (Rahimian, et al., 2017). They therefore only appear on the site for very short assembly times and further instructions and site meetings. This tends to reduce bureaucratic processes and ensure that construction activities are well streamlined and coordinated to yield excellent results to the achievement of the client’s aim.

Performance of MiC

Modular integrated construction has become a bane in the recent discussions in the construction industry. It is seen as a paradigm shift from the on-site construction that is very much paramount in the erection of buildings (Liu, Martin and Easthope, 2019). So, its performance when being adopted needs to be of quality standard, flexible, affordable, and acceptable to all and friendly to the environment (Tong, 2021). Economy and construction cannot be separated because the latter needs the former to survive and function optimally (Shubham and Jalindar, 2019). Three vital indices namely, cost, quality and time, comes to mind whenever economy or project efficiency is being mentioned or brought to the fore. Reducing cost, time and improving quality are major concerns for both consumers and manufactures in the building industry. When compared to conventional construction methods, the prefabricated construction system provides significant reductions in time stating specifically that prefabrication is less than half of on-site construction (Lawson, Ogden and Bergin, 2012).

The society as it relates to construction, is the people that carry out the construction activities as well as the people that occupies the surroundings where the construction is being carried out (Bhosale and Kulkarni, 2017). Indices of the society in construction projects reflects the extent to which the lifecycle of construction projects meets the demands of anticipated or existing social demands (Khan, et al., 2022). Indices such as workers’ health and safety, health of occupants, labour availability, construction quality, labour availability, aesthetics, constructability, traffic congestion and community disturbance are considered indices of society since them directly or indirectly affect people related to the construction exercise. In comparison between modular construction and conventional construction considered these indices by researchers (Kasim, et al., 2018; Chen, Okudan, and Riley, 2010). When compared to the conventional on-site construction practices, modular construction system improves worker’s health and safety due to cleaner and good working environments (Boafo, Kim and Kim, 2016). This invariably reduces construction noise, dust and other pollutants faced by nearby community.

The construction sector is highly resource and energy intensive; it is therefore imperative that it moves towards a path of environmental sustainability (Mao, et al., 2013). Modular integrated construction system improves sustainability in construction and provides environmental benefits (Moghayedi, et al., 2021). Modular buildings result in fewer emissions of obnoxious greenhouse gases than conventional buildings in the construction phase. Indices of the environment such as construction waste, pollution generation, energy consumption and water consumption, formwork consumption, site disruption were taken into consideration by many researchers in comparing the benefits of modular construction system with that of conventional methods (Zakaria, et al., 2018).

Research methodology

Quantitative research design was used to obtain the opinions of construction professionals that provide construction services using MiC techniques. Multistage sampling technique was adopted in this study. Cluster sampling was first adopted in selecting the study’s location, which are Lagos State and Abuja in Nigeria. These two clusters are deemed suitable and most beneficial due to the sufficiency of MiC-compliant companies compared to other States in Nigeria (Ogunde, et al., 2016). This helped to ensure representation from different geographical regions and mitigate bias that may arise from focusing solely on one location (Akinradewo, et al., 2023). Thereafter, purposive sampling technique was adopted to identify construction organisations with practical experience in MiC techniques due to the non-availability of official directory of construction firms that use MiC techniques on construction projects in both Lagos and Abuja. Various criteria such as number of completed MiC projects (i.e., more than 20 projects); registration with the Corporate Affairs Commission (CAC) of Nigeria; and up-to-date websites that clearly indicates the professional services they offer were used to select construction companies with expertise in MiC techniques. These criteria are useful to enhance the sampling process and credibility of the target respondents.

A total of ten (10) MiC compliant companies were identified, comprising of five from Lagos and the other five from Abuja. The construction professional who works for these ten (10) organisations makes up the target population of this study (see Table 1). This is crucial to guarantee that the data received is an accurate reflection of the professional perspective with regards to MiC in Nigerian construction industry. A staff member from each organization was contacted via LinkedIn to reach out to the target respondents. The ten staff members of each construction organisation provide information on the number of professionals with hand-on experience in MiC projects. Through this, the population of the target respondents was determined as shown in Table 1. The ten staff members assisted in disseminating the electronic questionnaire to the identified professionals within each organization.

Note: Arch. = architect, QS = quantity surveyors, Engr. = engineers, PM = project managers

The questionnaire used to elicit the opinion of the target respondents comprised of three sections, namely background information, variables of MiC indicators and the items of performance metrics obtained from extant literature. The variables of MiC indicators and performance metrics were asked on a five-point Likert scale in which 1 represented “strongly disagree”, 2 represented “disagree”, 3 referred to “neither agree or disagree”, 4 represented “agree”, and 5 stood for “strongly agree” (Vagias, 2006).

Based on the population, it can be deduced that a total of ninety-three construction professionals received the electronic questionnaires in the ten construction companies, in which 48 copies of the questionnaire was distributed to the five companies in Lagos State, while remaining 45 was distributed to the other five companies in Abuja. Out of the forty-eight questionnaires distributed to the five MiC practicing construction companies in Lagos state, thirty-four were retrieved, representing 70.83% response rate (see Table 2). Meanwhile, only twenty-six were retrieved from the construction companies in Abuja, representing a response rate of 57.77%. In total, sixty questionnaires were received, with an overall response rate of 64.52%. The response rate was considered sufficient as it is greater than the 20–30% often recommended in construction-related studies (Moser and Kalton, 1971). The data returned were thoroughly checked for incompletely filled items in any of the sections or response with the same rating across the survey to ensure validity of the data, and all the data were found suitable for analysis.

| Location | Questionnaire administered | Questionnaire retrieved | Response percentage |

|---|---|---|---|

| Lagos | 48 | 34 | 70.83% |

| Abuja | 45 | 26 | 57.77% |

| Total | 93 | 60 | 64.52% |

The data received were analysed with both descriptive and inferential statistics, namely mean score, standard deviation (SD), factor analysis, reliability test, and Pearson correlation of the social sciences (SPSS version 23). Factor analysis was used to group the MiC indicators into manageable sizes for easy discussion and simplicity of further analysis (Reio and Shucks, 2015; Oladinrin, Jayantha and Ojo, 2022). With the 60 data and 20 variables, the study meets the minimum sample size to item ratio of 1:3 (Cattell, 1978; Mac Callum, et al., 1999). Cronbach’s alpha was used to determine the internal consistency of the factors generated in the factor analysis (Norusis, 2011). Mean score and SD were used to determine the rating of the respondents on the performance metrics. Finally, correlation analysis was used to understand the interaction between the MiC indicators and performance metrics after data transformation in SPSS (Tabachnick and Fidell, 2007).

Data analysis and results

Background information of respondents

The respondents in this study comprised quantity surveyors (35.0%), builders (21.7%), engineers (20.0%), architects (18.3%), and project managers (10.0%). Most of the respondents (86.7%) currently work in a private indigenous organization and 13.3% works in multi-national organisations (see Table 3). Majority of the respondent (78.3%) works in medium-sized establishments (i.e., organisation with 50-249 staff), while others are engaged in small-sized firms. Furthermore, the majority of the respondent have an average of five years working involvement in MiC projects and 46.7% of the respondent have executed over 8 MiC project. This indicates that the information provided by the respondents could be relied upon.

Factor analysis

The MiC indicators were factor analysed by varimax rotation. The adequacy of the data set revealed a Kaiser-Meyer-Olkin (KMO) of 0.601. Based on the results of the sampling adequacy with significant level of 0.000, the degree of freedom (df) of 276 and approximate chi-square values of 888.551. The Bartlett’s test of sphericity for the correlation adequacy between the items can be adjudged significant (Shen and Liu, 2003; Oladinrin, Jayantha and Ojo, 2022). It implies that the items constituting the indicators will significantly correlate at 5% level, therefore, exploratory factor analysis is satisfactory. Cronbach’s alpha value for internal consistency was also used to test the dataset grouping’s dependability. The alpha values of the four MiC indicator were 0.725, 0.746, 0.612, and 0.697 (see Table 4). These alpha values are higher than minimum benchmark of 0.6; thus, they can be considered satisfactory (Hair, et al., 2010).

The result of the factor analysis shows that four groupings were obtained for the indicator. Giving names to factors generated in the factor analysis is majorly subjective and more of art (Yong and Pearce, 2013). Factors can be named based on similar constituting items in the factor (Oladinrin and Ojo, 2021), or by a common theme established in previous studies (Zhang, et al., 2018). Therefore, the study ensured that the factor name is largely a representation of the constituting items. Based on the result in Table 4, the names given to the factors formed for the indicators are Sustainability Factor (SUI), Procedural Factor (PRI), Cost Factor (COI), and Internal Factor (INI).

Performance metrics on MiC

The mean item score and SD for each variable of performance metrics based on an established groupings (Lawson, Ogden and Bergin, 2012; Murali and Sambath, 2020; Shubham and Jalindar, 2019) are presented in Table 5. The overall mean score forms the basis for ranking of the factors. In addition, the standard deviation is provided to rank factors with same mean values. The mean scores of nine of the sixteen measures of performance are more than 4.0, revealing their importance (see Table 5). It is important to note that the factor analysis was not conducted on the variables of performance metrics of MiC because the groupings have been validated in previous studies (Murali and Sambath, 2020). To further validate the data obtained, the alpha values of the performance are 0.636, 0.647 and 0.814 which shows to be on an adequate benchmark. These α values are above 0.6, and can therefore be considered satisfactory (Hair, et al., 2010).

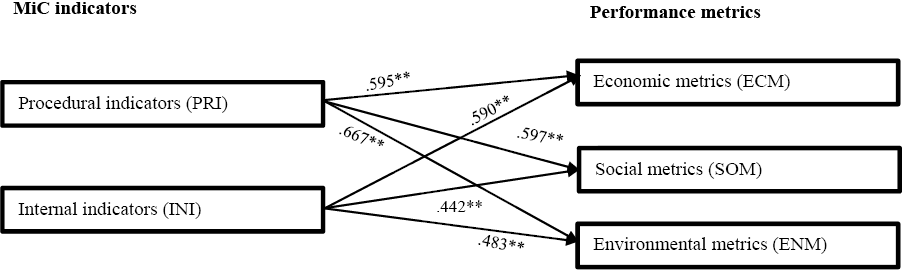

Correlation between indicators and performance metrics

Correlation analysis was conducted to examine the relationships between the MiC indicators and the performance metrics. Similar studies have utilized this strategy (Ojo, Adeniyi and Ogundimu, 2022), as a result of this, the method is thought to be appropriate for this study. The correlation was conducted after transforming each variable that constitutes the factor by obtaining the average of the summation in SPSS (Tabachnick and Fidell, 2007). The results of this Pearson correlation analysis show that two-tailed data are considered to be significantly correlated at the 0.01 level in Table 6. A positive correlation coefficient indicates that an increase in a particular performance metric will also result in an increase in that indicator, and a negative correlation indicates an inverse relationship between the variables, in which one increases while the other decreases (Oladinrin, Ogunsemi and Aje, 2012).

The result shows that two indicators PRI and INI have significant positive correlation with all the performance metrics (ECM, SCM, and ENM), while the other indicators, i.e., SUI and COI have no significant connection with any of the performance metrics.

| MiC Indicators | Performance Metrics | ||

|---|---|---|---|

| Economic Metric | Social Metric | Environmental Metric | |

| SUI: Sustainability indicator | -.047 | .029 | -.040 |

| PRI: Procedural indicator | .595** | .597** | .667** |

| COI: Cost indicator | -.049 | .249 | .230 |

| INI: Internal indicator | .590** | .442** | .483** |

Note: ** = Correlation is significant at the 0.01 level (two-tailed).

Discussion

The relationship between the MiC indicators and the performance metric is illustrated in Figure 1.

Figure 1. Relationship between the indicators to MiC and the performance metric of MiC

→ represents positive significant relationship confirmed by correlation.

The relationships between procedural indicator of MiC including construction time, concurrency of operation, health of building occupants, labour availability, and technological capability and the three performance outcomes, namely economic, social, and environmental is confirmed in this study. The relationships depict that the procedural element can enhance economic performance. This study’s findings are consistent with those of Lawson, Ogden and Bergin (2012), who asserted that the prefabricated construction system significantly reduces construction time compared to conventional methods. Based on the study of Wai, et al. (2023), construction project of 3-storey was completed within 4 days in the US, 57-storeys completed in 19 days in China, and 10-storey building completed in 26 days in Singapore through MiC. On the other hand, Egege (2018) concurs with the discoveries on financial measurements of MiC, believing that the fuse of secluded development will lessen development costs by 5-10%. This suggests that the implementation of the procedural factors identified by this study’s finding can reduce building construction costs in order to record more positive economic metrics overall (Wuni, Shen and Mahmud, 2022). The findings of this study also disputed submission that the primary financial obstacles that MiC faces in comparison to conventional construction methods are the higher initial costs as well as transportation costs (Pan and Hon, 2020). This shows that when the expense is high or low, there is a comparing inverse effect on the financial measurements for passing judgment on the presentation of a structure, which is not in agreement with this study’s discoveries. Therefore, by given attention to the procedural factors identified in the study, Nigerian construction firms can strive towards achieving better cost-effectiveness, project efficiency, and sustainability. This in turn, could contribute to the growth and development of the construction industry in Nigeria.

The results of the study also revealed that procedural indicators play a crucial role in determining how social performance is affected. This is on the grounds that structures are being built for people’s (society’s) utilization and accordingly, their needs should be considered. This assertion is supported by Bhosale and Kulkarni (2017), who place people at the centre of construction activities and rely on the effectiveness of procedures to ensure that these activities are carried out. For MiC to be fully integrated into construction for society’s maximum benefit, these indices need to be better improved, hence concurring with the findings of the study. By advancing sustainable construction, MiC guarantees the requirements in terms of materials conservation, controlled environment, reduction in noise and air pollution, and also reduction in solid waste and wastewater. Thus, considering the Nigeria’s growing urbanization and infrastructural needs, adopting MiC can help minimize the environmental footprint of construction activities and mitigate the impact of construction-related pollution that is detrimental to the health of construction workers and the society at large. Mao, et al. (2013) indicated affirmatively that the construction sector is highly resource and energy intensive and therefore, it is imperative that it moves towards a path of environmental sustainability. According to the findings of this study, these outcomes can only be enhanced by increasing these procedural factors.

The study has affirmed the connection between internal indicator of MiC factors and the three performance outcomes. These intrinsic internal factors stem from community disturbance, travel congestion and logistics which can exert some influence on the environment and social performance of a building. With the majority of activities carried out off site, the waste generated being controlled, recycled and reused, this simplifies the construction process and diminishes wastes materials from construction site. Also, with the reduced construction noise and pollution to the community, the impact to the community is reduced which can improve the choice of this construction procedure. The findings of this study concur with submission that noise is a great disturbance to the community and has a negative impact on the environment despite the improvement in noise barriers used in construction sites used in Denmark and other European nations (Bendtsen, 2010). In addition, Nabi and El-Adaway (2020) findings also agree with this as they consider MiC to be a quiet course of development, subsequently not influencing the environment directly, like the traditional technique for development.

On-site construction noise pollution is a significant environmental disturbance that affects construction workers and the surrounding community. However, logistics play a role in MiC; for instance, the transportation of the modules to the installation site demonstrates the importance of logistics in terms of social behaviour execution quality. In Nigeria, where road infrastructure and transportation networks may be congested in commercial cities such as Lagos, logistics can pose significant challenges to the efficient implementation of MiC projects. This concurred with the study of Murali and Sambath (2020) that prefabrication construction method is beneficial in urban areas where traffic congestion may be avoided. This aspect may have to do with where the construction is located, which directly impacts economic performance. The construction professionals who are responsible for the manufacturing of modular homes through MiC are responsible for their own transportation. This indicates that when the cost of transportation is high or low, there is a relating impact on the economic metrics for judging the performance of a building project. In light of these findings, Hong, et al., (2016) concluded that cost of transportation has an impact on MiC’s economic metrics. Pan and Hon (2020) study’s result also depicts the findings. In their research, they stated that the higher initial and transportation costs are the main economic hurdles that MiC faces in comparison with conventional construction methods. Therefore, addressing economic challenges related to transportation cost is essential for unlocking the full potential of MiC as a viable construction solution in Nigeria’s rapidly evolving urban development. It is important to note that developed nations such as US deployed the use of digital twin methodology using building information modelling (BIM), Internet of Things (IoT) and Geographic Information System (GIS) data to manage the transport-related issues for MiC (Lee and Lee, 2021). Therefore, developing nations can also learn the methodology to mitigate transportation problems on MiC projects.

Recommendations

The idea that MiC’s implementation procedures are crucial indicators of its adoption for the construction process is revealed in this study. MiC projects’ performance is heavily influenced by the procedures and techniques used by construction professionals and stakeholders. However, based on the findings of this study, it is recommended to organize comprehensive awareness campaigns targeting industry professionals and stakeholders for promoting the integration of technology in construction operations. The Nigerian construction industry could consider implementing a MiC certification program similar to Australia’s model (AUMANUFACTURING, 2022) to increase awareness, knowledge of MiC, safety, and promote sustainability in modular construction project. In addition, it is advocated that the National Building Code be amended, implemented and enforced in all construction activities. This code covers all the different ways the building can be used well by people (society). To ensure that construction products are effective and efficient, the industry needs to be made safer and less harmful for professionals and workers. MiC can be well integrated by implementing these recommendations to ensure that the building’s social performance improves after construction because construction cannot be done alone.

As far as the environmental metrics of buildings, Nigeria has been perceived as a pacesetter in most related issues in Africa and the cynosure of everyone’s eyes in Europe and different mainland. It is basic that it shows same pacesetting trait in hugely taking on development advances like MiC in her development area. The wastages, and energy utilization of structures ought to be managed by the specialists by carrying out a more secure and all the more harmless to the ecosystem processes into development exercises. By using noiseless off-site fabrication and/or on-site coupling, construction noise should also be drastically reduced.

Conclusion

The research mainly focused was to investigate the relationships between MiC indicators and performance metrics through survey of professionals with practical experience in the use of MiC in executing infrastructure in Lagos and Abuja. The study grouped the MiC indicators identified from other studies to four groups: sustainability, procedural, cost and internal indicators. Both procedural and internal factors are significant indicators to all the three-performance metrics (economic, social and environment performance). The study demonstrated that the impact of MiC is extremely beneficial in all construction ramifications, ensuring that the project outcome is socially, environmentally, and economically sustainable. Based on the findings of this study, it is suggested that massive awareness campaigns regarding the necessity of using technology in construction activities be launched among professionals and stakeholders in the construction industry as well as across all social classes. In addition, the study’s procedural factors should be better implemented by the Nigerian construction government to ensure that the construction outcome (building) performs economically. In order to promote construction sustainability in accordance with globally acceptable practices, this is sufficient motivation for its inclusion, adoption, and implementation in all construction sites throughout the nation. The study was restricted to the viewpoints of construction professionals participating in the MiC, opinions of end users and case studies on MiC performance can be taken into account in future studies.

Data availability statement

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abdelmageed, S. and Zayed, T.A., 2020. Study of literature in modular integrated construction- Critical review and future directions. Journal of Cleaner Production, [e-journal] 277, 124044. https://doi.org/10.1080/15623599.2021.1907525

Ade-Ojo, O.C., Adewunmi, B.O. and Akinola, J.A., 2016. Susceptibility of building elements to rework in selected higher educational buildings in Nigeria. 21st Century Human Habitat: Issues, Sustainability, and Development, pp.1145-50.

AuManufacturing, 2022. New AMGC report highlights “depth and breadth of manufacturing” in Australia. [online] Available at: https://www.aumanufacturing.com.au/new-amgc-report-highlights-depth-and-breadth-of-manufacturing-in-australia (Accessed 10 March 2024).

Akinradewo, O., Aigbavboa, C., Aghimien, D., Oke, A. and Ogunbayo, B., 2023. Modular method of construction in developing countries: The underlying challenges. International Journal of Construction Management, [e-journal] 23(8), pp.1344-54. https://doi.org/10.1080/15623599.2021.1970300

Ali, A.H., Kineber, A.F., Elshaboury, N., Arashpour, M. and Daoud, A.O., 2023. Analysing multifaceted barriers to modular construction in sustainable building projects: a comprehensive evaluation using multi-criteria decision making. International Journal of Construction Management, [e-journal] https://doi.org/10.1080/15623599.2023.2299557

Bah, E.H.M., Faye, I. and Geh, Z.F., 2018. Housing Market Dynamics in Africa. London: Palgrave Macmillan. https://doi.org/10.1057/978-1-137-59792-2

Bello, W., Akinade, O., Ajayi, S., Oyedele, L., Bilal, M. and Alaka, H., 2023. Critical success factors for implementing circular economy in the construction industry. Resources, Conservation & Recycling, [e-journal] 185, p.106511. https://doi.org/10.1016/j.resconrec.2022.106511

Bendtsen, H., 2010. Noise Barrier Design: Danish and some European Examples. Supplementary Studies for Caltrans QPR Program. Reprint report: UCPRC-RP-2010-04 [pdf online] Available at: https://dot.ca.gov/-/media/dot-media/programs/research-innovation-system-information/documents/final-reports/ucprc-rp-2010-04.pdf

Bhosale, A. and Kulkarni, S., 2017. Comparative study of prefabrication constructions with cast-in-situ construction. International Journal of Advance Engineering and Research Development, [e-journal] 4(3), pp.779-85. https://doi.org/10.21090/IJAERD.95630

Boafo, F.E., Kim, J.H. and Kim, J.T., 2016. Performance of modular prefabricated architecture: case study-based review and future pathways. Sustainability, [e-journal] 8(6), p.558. https://doi.org/10.3390/su8060558

Cattell, R.B., 1978. The Scientific use of Factor Analysis in Behavioral and Life Sciences, New York: Plenum. https://doi.org/10.1007/978-1-4684-2262-7

Chen, Y., Okudan, G.E. and Riley, D.R., 2010. Sustainable performance criteria for construction method selection in concrete buildings. Automation in Construction, [e-journal] 19, pp.235-44. https://doi.org/10.1016/j.autcon.2009.10.004

Dupwa, R.P., 2017. Investigation of the Utilization of Modular Construction in South Africa. MSc. University of the Witwatersrand, Gauteng, South Africa. https://hdl.handle.net/10539/25495

Egege, C.O., 2018. Off-site modular construction as a method of improving construction quality and safety. International Journal of Structural and Civil Engineering Research, [e-journal] 7(3), pp.259-68. https://doi.org/10.18178/ijscer.7.3.259-268

Goodier, C.I. and Gibb, A.G., 2007. Future opportunities for offsite in the UK. Construction Management Economic, [e-journal] 25, pp.585–95. https://doi.org/10.1080/01446190601071821

Hair, J.F., Black, W.C., Babin, B.J. and Anderson, R.E., 2010. Multivariate Data Analysis, 7th ed. London: Prentice Hall, Pearson.

Hong, J., Shen, G.Q., Mao, C., Li, Z. and Li, K., 2016. Life-cycle energy analysis of prefabricated building components: an input–output-based hybrid model. Journal of Cleaner Production, [e-journal] 112, pp.2198-2207. https://doi.org/10.1016/j.jclepro.2015.10.030

Humphrey, D., 2018. Dimensions and indicators for sustainable construction materials: A review. Research and Development in Materials Science, 3(4), pp.1-9. https://doi.org/10.31031/RDMS.2018.03.000568

Hussein, M., Darko, A., Eltouckhy, A.E. and Zayed, T.F., 2022. Sustainable logistics planning in modular integrated construction using multimethod simulation and Taguchi approach. Journal of Construction Engineering and Management, [e-journal] 148(6), 04022022. https://doi.org/10.1061/(ASCE)CO.1943-7862.0002273

Jiang, Y., Zhao, D., Wang, D. and Xing, Y., 2019. Sustainable performance of buildings through modular prefabrication in the construction phase: a comparative study. Sustainability, [e-journal] 11, 5658. https://doi.org/10.3390/su11205658

Kamali, M. and Hewage, K.N., 2015. Performance indicators for sustainability assessment of buildings. In: ICSC15 2015 The Canadian Society for Civil Engineering 5th International/11th Construction Specialty Conference. Vancouver, British Columbia, June 7-10, 2015. https://doi.org/10.14288/1.0076427

Kasim, T., Li, H., Rezgui, Y. and Beach, T., 2018. Integrated Framework to Manage Building’s Sustainability Efficiency, Design Features and Building Envelope. In: Camarinha-Matos, L., Afsarmanesh, H. and Rezgui, Y., eds. Collaborative Networks of Cognitive Systems. PRO-VE 2018. IFIP Advances in Information and Communication Technology, 534, pp.650-60. https://doi.org/10.1007/978-3-319-99127-6_56

Khan, A., Yu, R. and Liu, T., 2021. A Systematic review of risks in modular integrated construction practice. In: Proceedings of the 44th AUBEA Conference, Geelong, Australia, 27–29 October 2021. pp.344–54.

Khan, A., Yu, R., Liu, T., Guan, H. and Oh, E., 2022. Drivers Towards Adopting Modular Integrated Construction for Affordable Sustainable Housing: A Total Interpretive Structural Modelling (TISM) Method. Buildings, [e-journal] 12(5), p.637. https://doi.org/10.3390/buildings12050637

Lawson, R.M., 2008. Building Design Using Modules. [online pdf] The Steel Construction Institute, UK. Available at: https://www.steelconstruction.info/images/6/67/SCI_P348.pdf

Lawson, R.M., Ogden, R.G. and Bergin, R., 2012. Application of Modular Construction in High-Rise Buildings. Journal of Architectural Engineering, [e-journal] 18(2), pp.148-54. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000057

Lee, D. and Lee, S., 2021. Digital twin for supply chain coordination in modular construction. Applied Sciences, [e-journal] 11(13), 5909. https://doi.org/10.3390/app11135909

Liu, E., Martin, C. and Easthope, H., 2019. Poor-quality housing and low-income households: review of evidence and options for reform. International Journal of Scientific and Research Publications, 10(4), pp.1-17.

MacCallum, R.C., Widaman, K.F., Zhang, S. and Hong, S., 1999. Sample size in factor analysis. Psychological Methods, [e-journal] 4(1), pp.84-99. https://doi.org/10.1037/1082-989X.4.1.84

Mao, C., Shen, Q., Shen, L. and Tang, L., 2013. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Building, [e-journal] 66, pp.165-76. https://doi.org/10.1016/j.enbuild.2013.07.033

Moghayedi, A., Awuzie, B., Omotayo, T., Le Jeune, K., Massyn, M. and Ekpo, C.O., 2021. A critical success factor framework for implementing sustainable innovative and affordable housing: A systematic review and bibliometric analysis. Buildings, [e-journal] 11(8), 317. https://doi.org/10.3390/buildings11080317

Moser, C.A. and Kalton, G., 1971. Survey Methods in Social Investigation, 1st ed. London: Routledge. https://doi.org/10.4324/9781315241999

Murali, K. and Sambath, K., 2020. Sustainable performance criteria for prefabrication construction system. International Journal of Scientific and Research Publications, [e-journal] 10(4), pp.455-58. https://doi.org/10.29322/IJSRP.10.04.2020.p10052

Nabi, M.A. and El-Adaway, I.H., 2020. Modular construction: Determining decision making factors and future research needs. Journal of Management Engineering, [e-journal] 36, 4020085. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000859

Norušis, M.J., 2011. IBMSPSS Statistics 19 Guide to Data Analysis. Upper Saddle River, NJ: Pearson Prentice Hall.

Ogunde, A., Selekere, T.E., Joshua, O., Kuboyi, P.O. and Omuh, I.O., 2016. Prefabrication Method of Building Construction in Lagos State, Nigeria. International Journal of Engineering Technology and Computer Research, 4(1), pp.88-100.

Ojo, L.D., Adeniyi, O. and Ogundimu, O.E., 2022. Rethinking green supply chain management practices impact on company performance: A close-up insight. Sustainability, [e-journal] 14, 13197. https://doi.org/10.3390/su142013197

Oladinrin, O.T., Jayantha, W.M. and Ojo, L.D., 2022. New work practices and their drivers in FIREB firms: evidence from Hong Kong. Journal of Corporate Real Estate, [e-journal] 25(3), pp.205-28. https://doi.org/10.1108/JCRE-04-2022-0008

Oladinrin, T.O. and Ojo, L.D., 2021. Characterization of the drivers of environmental management system implementation. Engineering, Construction and Architectural Management, [e-journal] 29(10), pp.3868-92. https://doi.org/10.1108/ECAM-04-2021-0356

Oladinrin, O., Ogunsenmi, D.R. and Aje, O.I., 2012. Role of construction in economic growth: empirical evidence from Nigeria. FUTY Journal of the Environment, [e-journal] 7(1), pp.50-60. https://doi.org/10.4314/fje.v7i1.4

Pan, W. and Hon, C.K., 2020. Briefing: Modular integrated construction for high-rise buildings. Proceeding of Institute of Civil Engineering Municipal, [e-journal] 173, pp.64–68. https://doi.org/10.1680/jmuen.18.00028

Rahimian, F.P., Goulding, J., Akintoye, A. and Kolo, C., 2017. Review of Motivations, Success Factors, and Barriers to the Adoption of Offsite Manufacturing in Nigeria. Procedia Engineering, [e-journal] 196(2017), pp.512-19. https://doi.org/10.1016/j.proeng.2017.07.232

Reio, T.G. and Shuck, B., 2015. Exploratory factor analysis: Implications for theory, research, and practice. Advances in Developing Human Resources, [e-journal] 17(1), pp.12-25. https://doi.org/10.1177/1523422314559804

Shen, G.Q. and Liu, G., 2003. Critical Success Factors for Value Management Studies in Construction. Journal of Construction Engineering and Management, [e-journal] 129(5). https://doi.org/10.1061/(ASCE)0733-9364(2003)129:5(485)

Shubham, D.A. and Jalindar, R.P., 2019. Prefabrication technology - A promising alternative in construction industry. International Journal of Science and Research, [e-journal] 8(8), pp.240-44.

Tabachnick, B.G. and Fidell, L.S., 2007. Using Multivariate Statistics. 7th ed. New York: Allyn and Bacon.

Tong, Y., 2021. Factors for optimizing time performance of modular construction: A review and evidence from Huoshenshan Hospital construction. In: Proceedings of the 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 13–15 May 2021. NJ, USA: IEEE. pp.45–48.

Tupenaite, L., Lill, I., Geipele, I. and Naimaviciene, J., 2017. Ranking of Sustainability Indicators for Assessment of the New Housing Development Projects: Case of the Baltic States. Resources, [e-journal] 6(4), p.55. https://doi.org/10.3390/resources6040055

Vagias, W.M., 2006. Likert-type scale response anchors. [pdf] Clemson International Institute for Tourism & Research Development, Department of Parks, Recreation and Tourism Management. Clemson University. Available at: https://media.clemson.edu/cbshs/prtm/research/resources-for-research-page-2/Vagias-Likert-Type-Scale-Response-Anchors.pdf

Wai, T.C., Wai, Yi, P., Olanrewaju, I.O., Abdelmageed, S., Hussein, M., Tariq, S. and Zayed, T., 2023. A critical analysis of benefits and challenges of implementing modular integrated construction. International Journal of Construction Management, [e-journal] 23(4), pp.656-68. https://doi.org/10.1080/15623599.2021.1907525

Wuni, I.Y. and Shen, G.Q., 2021. Exploring the critical production risk factors for modular integrated construction projects. Journal of Facility Management, [e-journal] 21, pp.56- 69. https://doi.org/10.1108/JFM-03-2021-0029

Wuni, I.Y. and Shen, G.Q., 2022. Towards a decision support for modular integrated construction: An integrative review of the primary decision-making actors. International Journal of Construction Management, [e-journal] 22, pp.1–20. https://doi.org/10.1080/15623599.2019.1668633

Wuni, I.Y., Shen, G.Q. and Mahmud, A.T., 2022. Critical risk factors in the application of modular integrated construction: a systematic review. International Journal of Construction Management, [e-journal] 22(2), pp.133-47. https://doi.org/10.1080/15623599.2019.1613212

Yang, Y., Pan, M. and Pan, W., 2022. Integrated offsite logistics scheduling approach for high-rise modular building projects. Journal of Construction Engineering and Management, [e-journal] 148(6), 04022032. https://doi.org/10.1061/(ASCE)CO.1943-7862.0002280

Yang, Y., Pan, W. and Pan, M., 2017. Manufacturing of modular buildings: A literature review. In: Proceedings of the Modular and Offsite Construction Summit, Shanghai, China, 10–12 November, pp.55–62. https://doi.org/10.29173/mocs52

Yong, H. and Pearce, A., 2013. A review of green building standards: Criteria, benefits, and strategies for sustainable construction. Construction Innovation, [e-journal] 13(1), pp.55-72.

Yu, C., Xu, X. and Lu, Y., 2018. Computer-integrated manufacturing, cyber-physical systems and cloud manufacturing - concepts and relationships. Manufacturing Letters, [e-journal] 6, pp.5-9. https://doi.org/10.1016/j.mfglet.2015.11.005

Zakaria, S.A.S., Gajendran, T., Rose, T. and Brewer, G., 2018. Contextual, structural, and behavioural factors influencing the adoption of industrialised building systems: A review. Architecture and Engineering Design. Management, [e-journal] 14, pp.3–26. https://doi.org/10.1080/17452007.2017.1291410

Zhang, W., Lee, M.W., Jaillon, L. and Poon, C.S., 2018. The hindrance to using prefabrication in Hong Kong’s building industry. Journal of Cleaner Production, [e-journal] 204, pp.70-81. https://doi.org/10.1016/j.jclepro.2018.08.190

Zhang, S., Rong, X., Bakhtawar, B., Tariq, S. and Zayed, T., 2021. Assessment of feasibility, challenges, and critical success factors of MiC projects in Hong Kong. Journal of Architecture and Engineering, [e-journal] 27(1), 04020047. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000452

Zhou, B., Rybski, D. and Kropp, J.P., 2013. On the statistics of urban heat island intensity, Geophysical Research Letters, [e-journal] 40(20) p.5486-91. https://doi.org/10.1002/2013GL057320