Construction Economics and Building

Vol. 24, No. 4/5

December 2024

RESEARCH ARTICLE

Takt Complementing Last Planner® System on Residential Construction Projects

William Power1,*, Derek Sinnott2, Patrick Lynch3

1 PhD Candidate, South East Technological University, Cork Road, Waterford, Ireland. T45 YR13, williepower2010@gmail.com

2 Senior Lecturer, South East Technological University, Cork Road, Waterford, Ireland. T45 YR13, derek.sinnott@setu.ie

3 Senior Lecturer, South East Technological University, Cork Road, Waterford, Ireland. T45 YR13, patrick.lynch@setu.ie

Corresponding author: William Power, Department of Architecture and Built Environment, School of Engineering, South East Technological University, Cork Road, Waterford, Ireland. T45 YR13, williepower2010@gmail.com

DOI: https://doi.org/10.5130/AJCEB.v24i4/5.8846

Article History: Received 07/10/2023; Revised 14/09/2024; Accepted 27/09/2024; Published 23/12/2024

Citation: Power, W., Sinnott, D., Lynch, P. 2024. Takt Complementing Last Planner® System on Residential Construction Projects. Construction Economics and Building, 24:4/5, 58–80. https://doi.org/10.5130/AJCEB.v24i4/5.8846

Abstract

Ireland is experiencing a national housing crisis, and this is replicated across several developed economies. This challenges governments and housebuilders to increase production whilst balancing human resource and supply chain constraints. Lean construction methodologies have enhanced project delivery in other sectors of the general construction industry. This study evaluates the outcomes of Last Planner® System and Takt planning implementation on two residential projects.

The study adopted a mixed methods approach utilising case study design and data collected from a literature review, site observation diary, site documentation analysis, and semi-structured interviews. Findings demonstrate schedule reduction opportunities through higher and more consistent PPC, reduction of cycle times, and enhanced adherence to start and finish dates. The study proposes a more holistic focus is needed on productivity improvement initiatives on the entire project scope as opposed to singular exercises on aspects like internal finishes alone. Increased inter-contractor communication and engagement led to a positive working environment with greater focus on the softer aspects of collaborative working. This study posits the discipline, detail, and diligence of Takt complements Last Planner System to deliver an enhanced production-system that betters traditional schedule milestones in residential project delivery.

Keywords

Lean Construction; Last Planner System; Takt; Collaboration; Cycle Time

Introduction

Ireland’s national housing strategy, Housing for All, commits that the housing system needs to be placed on a long-term economically sustainable footing. In 2022 Ireland saw the greatest number of homes delivered since 2008 (up 45.2% on 2021). It is critical therefore that the highest levels of value, quality, and efficiency are achieved to enable rapid delivery and value for money for the State and its taxpayers.

Construction is an integral component of national and global economic activity but has systemic, embedded problems that result in widespread dissatisfaction with the outcomes of many projects (Sarhan, Pasquire and King, 2017; Oakland and Marosszeky, 2017). Fundamental obstacles to improving productivity remain firmly in place, chief amongst them being the embedded mind-set and its traditional approach to construction project management. Research points to construction being inefficient globally with the same problems and underlying causes common everywhere.

The current state of planning in construction has been criticised for its inadequacies (Daniel, et al., 2020); principally accruing from a lack of collaboration between those involved in developing the plan (Hamzeh, et al., 2016). The Last Planner® System (LPS), a key tool of Lean construction (LC), is proposed as a means of coordinating project interactions and achieving more reliable production outcomes by encouraging collaborative planning between project participants (Ballard, et al., 2020). Takt planning is a structured planning method that adds consistency and rhythm to construction activities, as it structures the order of zones where work is focused, while regularising the execution of these tasks around a Takt time (Frandson, 2019). Takt planning has been used to deliver construction projects and phases of work within projects of different types and in different construction sectors, such as multi-family housing, healthcare, and manufacturing plants (Tommelein and Lerche, 2023).

Empirical research (Koskela, 2000; Hamzeh, 2009; Ballard, 2020) identifies poor schedule adherence as a key issue relating to dissatisfaction with construction’s value offering. There are numerous examples of LPS enhancing project outcomes however, on its own LPS does not bring the required discipline and rigour that construction execution requires to overcome traditional mindsets, behaviours, and approaches.

The following research question is posed: How can the integration of Takt with Last Planner® System enhance residential construction project delivery?

Literature Review

Dissatisfaction with Construction

Globally construction experiences the same issues relating to poor productivity, but Barbosa, et al. (2017) assert performance is not uniform, stating there are large regional differences, and major variations within the global construction industry. This is corroborated by Liu, Yi, and Wang (2020) noting poor performance existed in both third world and ‘modern’ countries, suggesting larger budgets and sophisticated technology didn’t positively influence productivity performance. The Construction Industry Institute (CII, 2015) issued findings on a worldwide construction study highlighting the following:

• Only 2.5% of projects defined as successful (scope, cost, schedule, & business).

• 25 to 50% waste in coordinating labour on a project.

• Management inefficiency costs owners between $15.6 and $36 billion per year.

• An estimated $4 billion to $12 billion per year is spent to resolve disputes and claims.

Rivera, et al. (2016) investigated research across 38 countries and found four common key non-performance indicators: Rework, cost overrun, schedule delay, and customer satisfaction. Additionally, AlSehaimi, Koskela, and Tzortzopoulos (2013) examined studies relating to schedule delays and cost overruns and found that 87% identified poor planning, 69% procurement problems, and 56% poor site management as the principal reason contributing to poor performance. These examples, plus identified repetitive quality failures (Hwang, et al., 2009; Hwang and Yang, 2014), cost overruns (Flyvbjerg, Bruzelius, and Rothengatter, 2003; Ansar, et al., 2014), increasing litigation (Love, et al., 2010), allied to weekly task completion rates of 50 to 60 per cent typically found in traditionally managed construction (Ballard and Howell, 1998; Ballard, 2000), support the claim that Traditional Construction Project Management practice has not consistently achieved schedule targets. This prompted leading researchers (Koskela, 2000; Koskela and Howell, 2001; Ballard and Howell, 2003) to suggest that a wider and more powerful theoretical foundation would be required for construction delivery, as the traditional conceptual models were mismatched with the reality of onsite construction operations (Koskela, 2000; Abdelhamid, 2004). This radical shift in the view of construction delivery compelled Koskela and Howell (2002) to propose that the prevailing conventional theory of project management was outdated and was failing in the delivery of modern complex projects in increasingly dynamic environments.

There are numerous examples in the literature of how the application of Lean and LC and its philosophy, methodologies, and techniques can improve construction project delivery (Koskela, 2000; Liu, Ballard, and Ibbs, 2010; Hamzeh, et al., 2016; Tommelein, 2017). Aside from gross optimism bias errors relating to timeline and budget to completion, an effective production planning and control system can greatly contribute to reduction of rework, better cost and schedule adherence through steering to targets, and resultingly increased customer satisfaction (Ballard, 2020). It is essential therefore, to examine shortfalls in traditional scheduling methods to ascertain where modern tools, thinking, and techniques can be complementary.

Critical Path Methodology

Construction project management has predominantly relied on the Critical Path Methodology (CPM) for over 60 years, but its traditional use has been critiqued for failing to address the needs of production management (Ballard and Tommelein, 2021). It is important to distinguish between ‘scheduling’ and ‘planning.’ According to Oberlender (2000), project scheduling is the process of determining the sequential order of the planned activities, assigning realistic durations to each activity, and determining the start and finish dates for each activity. Ballard and Tommelein (2021, p.22) add that scheduling is a process of assigning dates and times to planned tasks arranged in a logic network. This process is typically supported using CPM calculations to determine the overall duration of the project, identify float in the schedule, perform time-cost trade-off analysis, and decide on resource allocation and levelling.

Planning differs as it is the process of identifying all the activities necessary to successfully complete the project. According to Oberlender (2000), planning should be a prerequisite to project scheduling because there is no way to determine the sequence or start and finish dates of activities until they are identified. Planning also reviews decisions regarding the use of offsite fabrication, modularisation, or innovative solutions. Hamzeh (2009, p.60) adds that the planning process should not be judged only by the outcome deliverable such schedule, estimate, or strategic plan, but must become a continuous adaptive iterative process in quest for value.

Paz, et al., (2018) suggest network techniques such as the CPM method apply values for activities duration without considering the possible influence of ongoing change or risk factors. While CPM identifies a sequence of activities having the longest duration, it doesn’t reflect the interference of variation in length or timing of activities, or the impact of concurrent activities (Tommelein and Lerche, 2023). Therefore, a common criticism of CPM is that over-running tasks, in addition to scheduled tasks being ‘forced’ to commence because they have been committed by the CPM schedule, cause excessive and unnecessary work-in-progress and knock-on coordination, safety, quality, cost, and people related issues on projects (Ballard and Tommelein, 2021).

Notwithstanding the concerns raised, many clients mandate the use of CPM as a governance and progress reporting tool (Galloway, 2006) and this reinforces its presence on construction projects. Despite the widespread existence of CPM, both academics and practitioners alike have debated its shortfalls and have suggested alternative and complementary methodologies, like LPS, for the management of project controls, scheduling, planning, and execution.

Last Planner® System

A key concept in LPS is the provision of reliable workflow to work-crews to reduce uncertainty in the delivery process (Liu, Ballard, and Ibbs., 2010; Mossman, 2019; Ballard, 2020). LPS is a major waste reduction and elimination technique that addresses this unpredictability (Hamzeh, Ballard, and Tommelein, 2009; Howell, Ballard and Tommelein, 2010; Hamzeh, et al., 2016; Daniel and Pasquire, 2017; Power and Taylor, 2019; Ballard, et al., 2020). Ballard and Tommelein (2016, p.7) define the function of LPS as ‘the proper work of the system; its jobs’, and note these ‘jobs’ as:

1. Specifying what tasks should be done when and by whom, from milestones to phases between milestones, to processes within phases, to operations within processes, to steps within operations.

2. Making scheduled tasks ready to be performed.

3. Re-planning/planning to complete, to achieve project objectives.

4. Selecting tasks for daily and weekly work plans—deciding what work to do next.

5. Making release of work between specialists reliable.

6. Making visible the current and future state of the project.

7. Measuring planning system performance; and,

8. Learning from plan failures.

Planned Percent Complete (PPC) is a key metric of LPS and measures workflow reliability (Ballard and Tommelein, 2016) – a high PPC indicates a well-planned production process with tasks screened in advance, ensuring high workflow reliability between teams (Ballard, 2020). However, Ballard and Tommelein (2016, p.59) warn against placing too much focus on PPC figures, stating ‘…PPC could be 100%, productivity excellent, and a project still be falling behind schedule’. This emphasises the importance of using all functions of LPS to ensure PPC and productivity are linked to the overall milestone schedule (Hamzeh, Ballard and Tommelein., 2009; Mossman, 2019; Ballard, et al., 2020). As PPC is positively linked to productivity (Ballard, et al., 2007; Liu, Ballard, and Ibbs, 2010), it is critical for LPS users to ensure that teams executing the work are afforded the greatest opportunity of achieving high PPC (Power and Taylor, 2019). Additionally, Weinheimer, Schmalz, and Müller, (2017, p.915) suggest LPS can generate sustainability benefits by its application of core Lean concepts to construction: ‘…process consistency, increasing the reliability of all work and information flows, applying the pull principle, transparency, recognition of obstacles in time, and working in an integrated project team.’

LPS also has shortfalls and previous research (Frandson, Berghede, and Tommelein, 2014; Schöttle and Nesensohn, 2019) found that integrating Takt with LPS addresses some of these gaps.

Takt

Takt planning, a location-based planning method, is receiving increasing attention in academia and on construction projects (Lehtovaara, et al., 2021). The word ‘Takt’ or ‘Taktzeit’ in German means ‘beat,’ ‘rhythm,’ ‘cadence’ or ‘meter’, implying the regularity with which something gets done. In the production context, Hopp and Spearman, (2011) defined Takt time as: ‘…the unit of time within which a product must be produced (supply rate) in order to match the rate at which that product is needed (demand rate)’. It is a process design parameter used in production settings that asserts if a process proceeds too quickly it will overproduce, and if it goes slower there will be a bottleneck (Frandson, Berghede, and Tommelein, 2013). Another consideration is that in construction workers move around the work as opposed to the work moving to the worker, for example, through a manufacturing assembly line (Ballard and Howell, 1997). Frandson, Berghede, and Tommelein (2013) suggests the difference between Takt time planning and other location-based planning methods is this balance between ‘work waiting on workers’ and ‘workers waiting on work.’

Takt production visualises the construction process in a way that includes work packages, work sequences, and Takt areas (Haghsheno, et al., 2016; Dlouhy, et al., 2016). Construction can utilise Takt time as a work structuring methodology to align the production rates of trades by pacing work sequentially through planned zones creating continuous workflow, reliable handoffs, and an opportunity to continuously improve the production system; Takt time is a design parameter for labour-paced flow of work (Frandson, Berghede, and Tommelein, 2013). Frandson, Berghede and Tommelein (2014) posit the objective of Takt time planning is to help create a more stable environment for the LPS by actively designing continuous workflow for trade activities wherever possible. LPS then provides the control mechanism and stability of the production system. Previous research has shown how Takt-time planning and LPS complement one other in many ways (Frandson, Berghede, and Tommelein, 2014; Schöttle and Nesensohn, 2019). Takt introduces continuous flow and more standardised work to LPS thereby extending its existing function. LPS in turn introduces control to Takt and facilitates planning and adaptation where continuous flow is not possible (Frandson, Berghede, and Tommelein, 2014). LPS is critical to the deployment and control of Takt while also being a ‘catch-all’ for activities that don’t fit into the Takt plan or need to be removed from the Takt plan. Additionally, Takt extends the functions by placing more focus on the process analysis of operations at the phase planning stage (Frandson, Berghede, and Tommelein, 2014). Together LPS and Takt offer a workable planning and control framework that considers both the social and softer aspects in conjunction with the physics of production system design (Frandson, 2019).

Takt enhances LPS by introducing time and location. It also adds sequencing of activities, levelling of Takt wagons, and balancing of crew size. These features make Takt more efficient than LPS however, it is also fragile as any failure in the system can be detected and will have immediate impacts. This fragility means the project team must address problems immediately otherwise production ceases to flow. However, once the production system is refined, the critical benefit is that when a low percentage of the work has been completed the team can reliably predict with high accuracy when the project would finish based on current production outputs. Takt also exposes time and location waste resulting in obvious inefficiency becoming visible.

Both Takt and LPS have their individual shortfalls, and literature suggests combining the methods can create a more robust delivery process. There is a paucity of case study research that presents how Takt and LPS can work in practice.

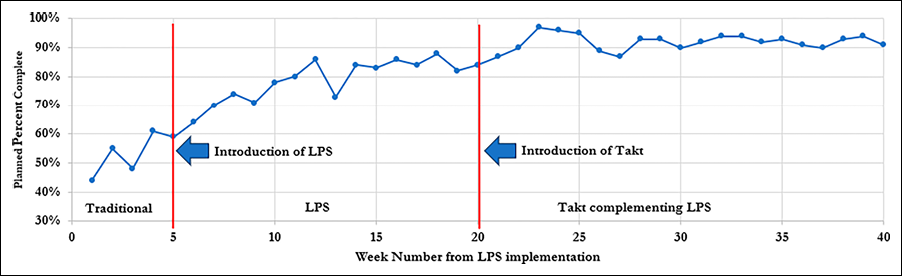

Methodology

The study is qualitative in nature and adopts a mixed methods approach employing case study, observational studies, documentation analysis, and interviews to examine the impact of Last Planner System and Takt planning implementation on two residential projects. Team members were trained on the principles and mechanics of LPS and Takt before the methods were introduced. The researcher assisted the implementation of LPS and Takt on the case projects. All interventions introduced were by the site teams. The research methodology is presented in figure 1.

Figure 1. Research methodology framework

Case studies offer distinct advantages not found in more quantitative research tools when a researcher is investigating into the ‘how and why’ of a set of events (Yin, 1993). It can ensure effective representation of the context where the knowledge was gathered is essential (Green, Kao, and Larsen, 2010). Research on Case Study 2 (CS2) commenced 10 weeks after commencement on Case Study 1 (CS1). LPS was implemented on CS1 and once embedded, Takt was then introduced to complement and enhance the planning process. CS2 followed the same method.

Project documentation was available in the form of CPM schedules, weekly and monthly project reports, minutes of meetings, weekly planning data (LPS pull plans, Lookahead reviews, weekly work plans, PPC reports, reasons for non-completion of tasks, constraint logs), and corrective actions issued to contractors. This documentation offered weekly qualitative and quantitative data that permitted trend analysis and uncovered themes for the interview questions. The researcher maintained a research diary on both projects and a daily report was maintained. This allowed thematic analysis of the diary records in accordance with Creswell (2009). In qualitative research with an exploratory nature, in-depth or semi-structured interviews should be used (Saunders, Lewis, and Thornhill., 2016). Unique sources were purposely sought to increase validity and to provide a wider research perspective, as advocated by Yin (2009) and Stake (1995). The interviewees were mature construction professionals at supervisor to management level within their organisations. They were familiar with the weekly planning process on the case projects. A panel of 12 potential interviewees was selected. As some were staff with the same contractor and others filled the same role, deselection left eight potential interviewees. Two declined to participate. The authors are satisfied that saturation has been achieved with six interviewees. Table 1 presents the selected interviewees and their roles on the two case projects.

The interviews were transcribed and analysed using a thematic analysis approach, as suggested by Braun and Clarke (2006). Re-reading and familiarisation of the transcripts permitted emerging data to be organised into different themes. These themes were again reviewed, and inferences drawn were checked by both data and methodological triangulation against the literature review findings. Limitations exist around the single case example and limited sample size. The absence of a ‘control’ group doesn’t allow comparison of how the project would have performed without the interventions.

Findings

Introduction

The company is one of the largest residential housing developers in Ireland delivering a large range of housing, duplexes, and apartments.

Case Study 1 (CS1) - The project is a mixed density residential project on a greenfield urban site. It is a low-density development with 40 housing units in 15 individual blocks and a high-density element of 8 duplex units with an apartment block of 24 units over 4 floor levels. The project is planned with a Primavera P6 schedule and has a total onsite duration of 62 weeks. In this study, a duplex unit refers to a two-storey house built on a ground floor apartment, each with a separate entrance.

Case Study 2 (CS2) - This project is a high-density residential development on another greenfield urban site. The project consists of 1100 apartments and duplex units in 10 individual blocks varying from 3 to 6 floors in height. This study focuses on 2 duplex blocks, each with 8 apartments on ground floor with 8 x 2 storey houses overhead, and an apartment block with 46 apartments over 5 floors.

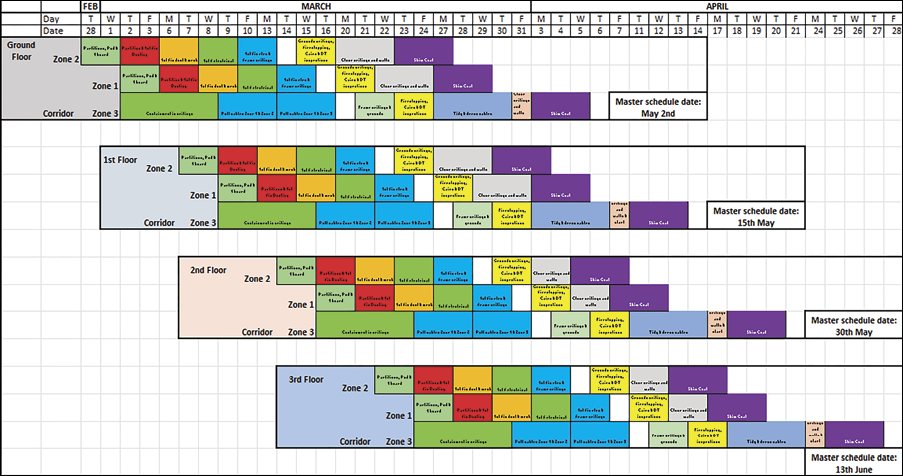

Both CS1 and CS2 ‘War Rooms’ had schedule milestones visible on the Pull Plans. Distinct Pull Plans were conducted for façade and roofing, internal works to completion per floor, and an external works plan incorporating utility provider inspections, documentation submissions from contractors, BCAR submissions, and client walkdowns for punch-listing. Key interface dates were linked and referenced across the ‘War Room’ on the Pull Plans. The internal works developed into a Takt plan, and the entire Block was controlled and steered by daily huddles tracking the weekly work plan that is validated at a weekly coordination meeting. This level of detailed lookaheads, tracking and constant readjustments as required contributed positively to the success achieved.

Findings on CS1

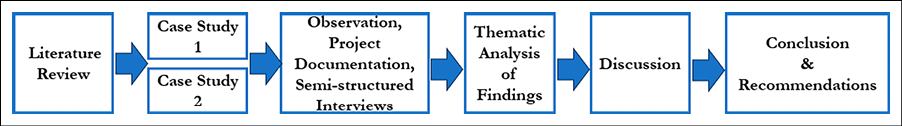

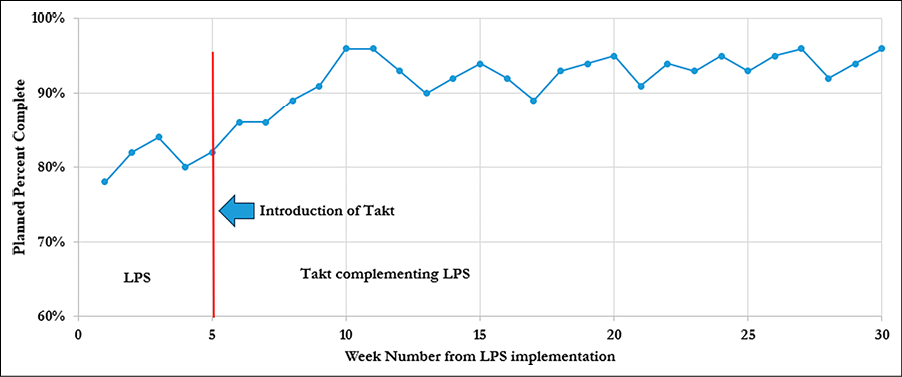

Weekly Performance PPC – Figure 2 presents the PPC from CS1 over the 40-week study and presents the PPC change from traditional planning methodology to LPS implementation and with takt complementing LPS.

Figure 2. Project planned percent complete

In the first 5 weeks on-line meetings were held with the Project Director and Site Manager to establish PPC for traditional style delivery. CPM tasks for each week were filtered from the Master Schedule and were measured as ‘complete’ or ‘not complete’ at weekend. LPS was introduced on the project on week 5 bringing noticeable improvement in task execution performance. Week 13 was impacted by strong winds and heavy rain ceasing all external works. Concepts of Takt planning were introduced at week 20 as the apartments internal works were commencing. Immediate early success was obvious over the following weeks accruing from the more diligent and onerous planning demanded from Takt application. Greater stability in subsequent weeks’ PPC is also obvious.

• Average PPC with Traditional Methods: (n=5 Weeks): 53%

• Average PPC with LPS: (n=15 Weeks): 79%

• Average PPC with Takt complementing LPS: (n=20 Weeks): 92%

The application of Takt to complement LPS resulted in a 16% increase in PPC.

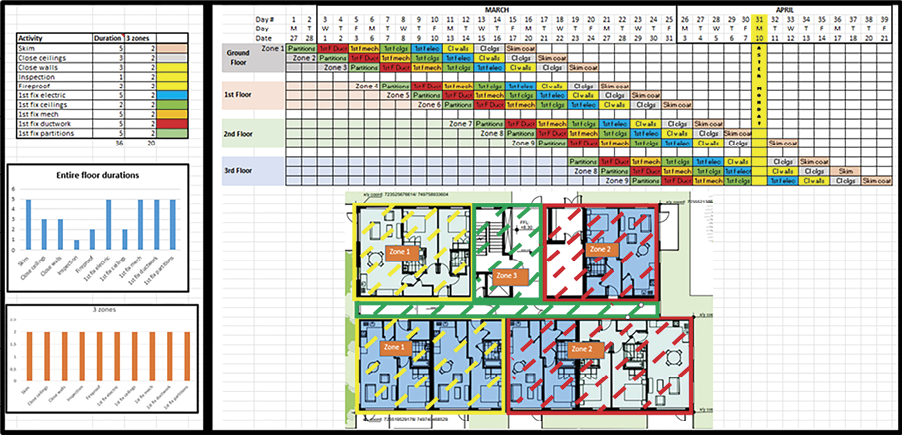

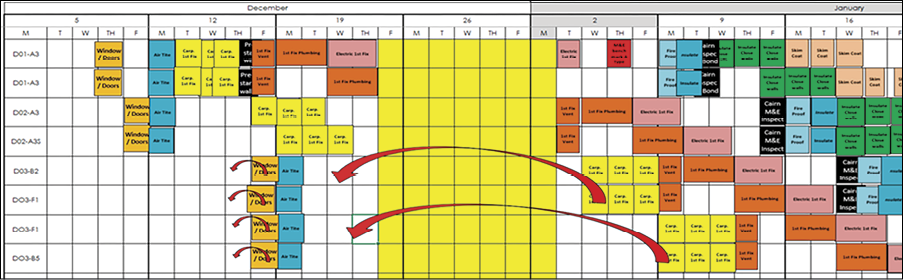

Cycle time reduction - Figure 3 presents some early white board exercises with trade supervisors where the work durations required in each block of 2 units were recorded with the objective of determining a cycle time from timber frame erection to skim coat complete. Earlier pull plans showed a 25-day cycle; this exercise suggested a 17-day cycle was achievable. When adding extra buffer, the team agreed on an 18-day cycle time. After initial challenges keeping this on track, further refinements were introduced, and the cycle time stabilised at 15 days – a 10 day or 40% improvement on the pull plan.

Figure 3. Introducing the concept of cycle time

Another cycle time reduction example related to the next sequence of activities from skim coat complete to the air test which was the final activity before offering to the client’s representatives for punch list inspection. The master schedule duration from skim complete to air test is 37 working days. With the pull plan logic, sequence, and duration exercise, including applying Takt concepts wherever possible, this was reduced to 26 days including some buffer. Despite this not being executed due to late delivery of fire-rated doors, the adherence to output of the exercise brought enhanced structure as well as better safety and quality to the work being executed. The act of aiming for the improved delivery date for the air test accommodated the delayed fire-door delivery and the air tests were achieved within the master scheduled dates. At 20 weeks into the implementation the internal partitions were about to commence in the apartment block. A more focused introduction of the concepts of Takt planning to complement LPS and to take advantage of the repetitive 6 apartments over 4 floors layout was adopted. Following agreement on three zones per floor – 1 x 2-bedroom and 2 x 1-bedroom apartments were batched to give zones 1 and 2. The common area of corridor, stairwell, and lobby was zone 3. A process analysis exercise was conducted around agreeing how these zones and their work density could be addressed with each trade’s crew size, production output, and application of a fixed Takt time. The first iteration of this exercise is presented in Figure 4.

Figure 4. Exercises determining the Takt plan

Enhanced communication - Figure 4 presents exercises conducted to collate data, agree layout sizes, determine the process analysis, agree the sequence and durations, balance crew size and workflow, and to produce a production plan for testing in the apartment block. These exercises facilitated the increased communication that CPM would have struggled to initiate and maintain. The act of engaging in collaborative planning unearthed problems and challenges earlier than would normally occur in the field. This increased and shared communication allowed resolution of numerous issues that kept work flowing and minimised negative impacts. Immediately on issuance of the plan concerns began to emerge relating to the crew sizes. Some contractors had work packages subcontracted to independent contractors who had different size work crews. Some operated as 2 person crews where others had up to 12 resources available. To complicate matters further, some crew’s work packages had to be balanced by combining several housing units with apartments. Apartments were financially more attractive, so the principal subcontractors needed to allocate work carefully to ensure retention of resource on the site.

Visualisation offered an opportunity to consider a different approach to the mechanical and electrical works in the corridor circulation areas. It was defined as a distinct zone with standalone durations as shown in figure 5.

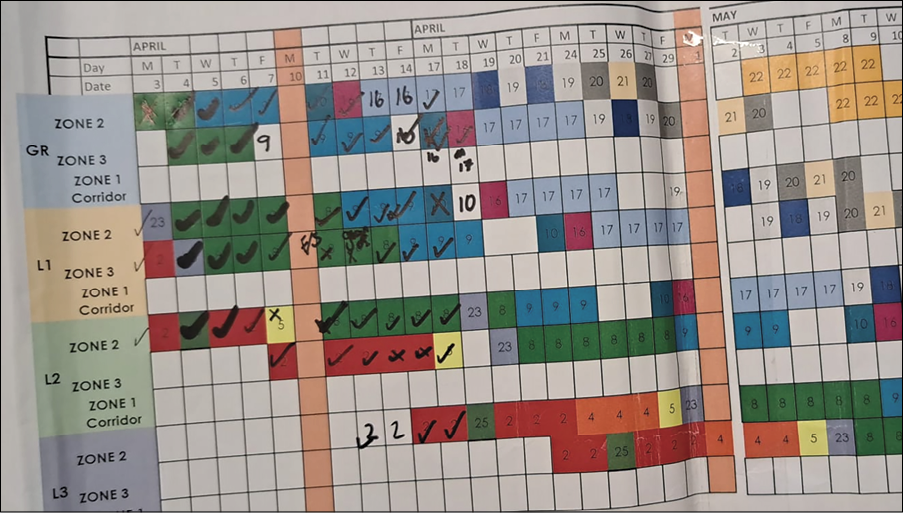

A hybrid application of true Takt concepts was compromised as a starting point, as major financial adjustments would have been required to the contractor’s packages to enable full Takt alignment. Further testing resulted in removing the corridor circulation areas from the visual plan and managing that work location through LPS Weekly Work Plan’s. A hybrid Takt visual plan as shown in figure 6 shows progress after two weeks, noting how the deliberate buffers were being used for any over-running activity durations.

Figure 6. Marking up of later Takt visual

All work was tracked daily and PPC was marked up weekly through LPS. Time buffer allowances were indicated with ‘white boxes’ and it can be seen in Figure 6 where some tasks were pulled ahead and others over-ran into the buffer. This buffer assisted keep all trades on track and ensured a single failure wouldn’t cause collapse of the entire process.

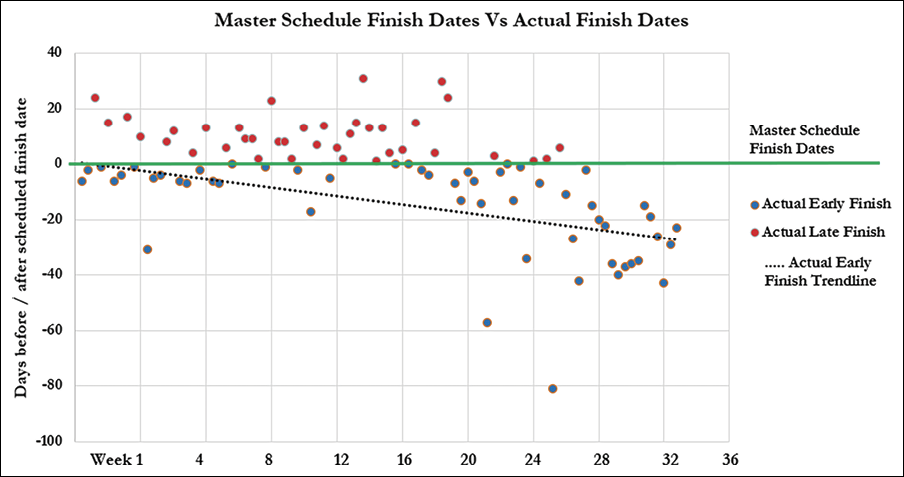

Milestone accomplishment - 92 dates were selected, focusing on key milestones of timber frame install, windows install, scaffold dropped, skim coat complete, and clean. Master schedule start and finish dates were compared with actual start and finish dates from site documentation and weekly LPS data. This offered 92 data points relating to start dates and 92 relating to finish dates. 54 (59%) of the activities commenced ahead of the scheduled start date. 53 (56%) of the activities were completed ahead of the scheduled finish date.

Figure 7. Master schedule finish dates versus actual finish dates

Figure 7 illustrates the challenge of adhering to master schedule dates with external works like timber frame erection, roofing, block, brickwork, and external rendering. Extended periods of poor weather affected site progress over the winter period (week 1 to 16) resulting in the number of late finishes of external tasks. However, the Actual Early Finish Trendline illustrates the improvement in achieving milestone dates. Despite the weather challenges, a cumulative of 131 days were saved across the 92 selected activities.

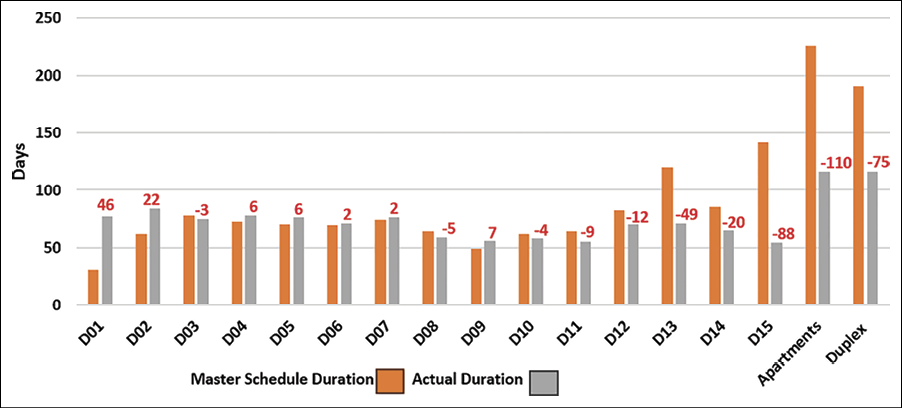

Scaffold duration - A key performance indicator on housing projects relates to scaffold durations and adherence to target scaffold dropped dates. Figure 8 presents actual scaffold standing durations against the master schedule durations.

Figure 8. Actual scaffold durations versus master programme durations

Considerable reduction in scaffold standing durations were achieved on multiple units, apartments, and duplex blocks, for example 41% and 62% reduction on 6-unit housing blocks, 49% reduction on the 24-unit apartment block, and 39% reduction on the 8-unit duplex block. Overall, the project’s actual cumulative scaffold standing duration was 284 days less than the master schedule planned time allocation, an 18% saving over the scheduled standing duration.

Opportunities to improve schedule - The external window and door contractor was due to install D03 windows on Friday but on enquiring were installing them a day earlier. This information only came to light when a question was asked in the pull plan session taking place that day. An opportunity existed to ‘pull’ air tightness and internal carpentry forward from after Christmas. Figure 9 presents the backlog opportunity.

Figure 9. Improvement opportunity identified

The Team hadn’t recognised this, but the contractors had seen the opportunity. However, this ‘opportunity’ needed to be resisted as ‘pulling’ already planned and committed resources forward into available space could have disrupted the flow that had already been agreed.

Interview findings – outcome correlation

Table 2 demonstrates the key outcomes from the interviews conducted on CS1. The interviewees comprise both management and contractor supervision and it is important to recognise that not every theme would resonate to the same degree with each interviewee depending on their involvement in the project.

The critical outcome from the interviews is the involvement of the contractors in the short- and medium-term planning process. The introduction of Takt concepts to complement LPS resulted in a more scientific examination of planning, durations, cycle times, crew size, and activity metrics.

Case Study 2 – High Density Residential Development (66 units)

CS2 refers to a 1600-unit high-density residential project composing a mix of apartments and duplex units in 12 separate blocks. This study focuses on two duplex blocks, each with 16 units, and an apartment block with 34 units. The researcher commenced on the project 10 weeks after he had initiated the implementation on case CS1. Therefore, many of the learnings from CS1 were immediately brought onto CS2 project. An initial introduction to LPS was given to relevant staff and then commenced with a pull plan on Block 4 apartments which included the mechanical, electrical, and dry wall contractors. The implementation on CS2 followed an emergent process starting with LPS, moving to a Takt ‘lite’ and then attempting true Takt on a project. Takt ‘lite’ is so called as it incorporates some concepts of Takt but due to specific challenges struggled to get full contractor buy-in. This will be explained further in the discussion section.

Findings on Case Study 2

Planned Percent Complete - PPC from CS2 is presented on Figure 10. This shows continuous improvement from an initial average 81% PPC to a more reliable 93% average PPC for the remainder of the project: a 13% increase by introducing Takt. However, the selected blocks were not without their interruptions as issues were experienced with kitchens delivery, fire doors delivery, access impacted by external drainage works, and availability of decorator’s resource. The daily and weekly planning routine mitigated impacts and the proactive lookaheads offered visibility of the upcoming issues before more adverse impacts were experienced.

Figure 10. Project planned percent complete

All 3 blocks were completed ahead of schedule. One was 6 weeks ahead of its 52-week schedule; Another was 3 weeks ahead of its 47-week schedule; and the 34-unit apartment block was 10 weeks ahead of its 66-week schedule. Respectively, this shows an 11%, 6%, and 15% schedule reduction since the implementation commenced.

Interview findings – Interviews were also conducted on CS2 and encompassed both site and contractor management. Findings that duplicated CS1 interviewees have been omitted from the CS2 findings and are presented in Table 3.

| Key Theme | Interviewee |

|---|---|

| Benefits in making individual contractors aware of the other contractor sequences and programme. | E, F, G, & H. |

| Brings schedule to the fore for every contractor. Focus on milestones and all contractor’s input to achieve the schedule. | E, F, G, & H. |

| Highlights risk around material orders and procurement required for the works being planned - frequently this does not happen with the lesser organised sub-contractors. | E & F. |

| Focuses attention and micro-management where the sequence is abnormal and needs day by day engagement. | F, G, & H. |

| Constant ‘flushing out’ of constraints in pull plans allows opportunity to resolve them as early as possible and mitigate adverse impacts. | E, F, G, & H. |

| A distinct ‘services and groundworks’ plan must be in place to ensure gains made during building construction and internal fitouts are not lost with over-running groundworks. | E, F, & G. |

Key additional points raised on CS2 interviews relate to increased contractor visibility of other contractor’s sequences and schedule in addition to the need for a broader focus on external works and documentation submission cycles to achieve project completion.

The creation of a psychologically safe environment where planning failures were not criticised was an important aspect of the implementation. This was introduced in the introductory LPS and Takt training and was considered a key enabler of the planning process. Interviewees A and E noted it was important not to be critical of failures or errors in the early stages of the implementation as resistance could accrue.

The following summary in bullet point format highlights collated findings from both projects examined. These focus on how the application of Takt enhanced the LPS implementation and brought additional value-add to the project, the management team, and the contractors.

Summary of collated findings from CS1 and CS2

• Distinct schedule reduction advantages were evident from Takt complementing LPS, especially in blocks of 6 units or more. Better opportunities existed on larger blocks particularly relating to work crews flowing in sequence through sized work zones.

• There was distinct PPC increase from traditional planning methods to LPS and more reliable and consistent higher PPC with the introduction of Takt. This predictability allowed more reliable forecasting of handoff dates like dropping of scaffold.

• The proven cycle time reduction in the assembly and internal finishing process allowed more balanced and coordinated resource provision and movement. Takt introduced consistency of workflow for the contractors.

• The importance of pulling from clearly defined and understood milestones ensured less ambiguity regarding scope and reduced return visits. Incorporating a clear quality vision and expectation clarified that no contractor was to leave a defect behind. Contractors were better able to plan through visualisation of the Takt planning process. Visualisation engages the contractors in better planning.

• The constraints process highlighted procurement risks early. This allowed for early intervention or escalation for redesign or work-around solutions. Contractors identifying constraints based on their experience brings greater awareness and anticipation of potential risks and reduces the likelihood of adverse events influencing the project outcome.

• The role of active management support and participation is fundamental to underpinning effective LPS and Takt implementation. Site supervision and contractor trade supervisors must witness genuine management support to the new methods and behaviours required for LPS and Takt planning. Embedding and sustaining the implementation needs a long-term view with visible and achievable successes along the journey.

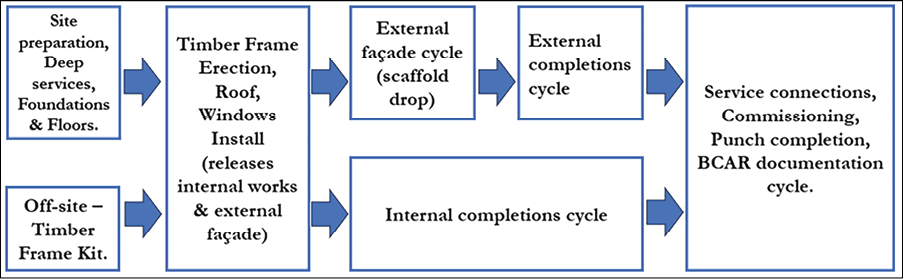

• A more holistic wider-project view is necessary for successful milestone achievement – optimising individual workstreams like internal finishes is insufficient for overall completion. All workstreams such as ground preparation, building frame, internal finishes, external façade, services, hard and soft landscaping, access and egress, and documentation must flow smoothly both sequentially and in parallel to allow successful project completion and handover.

Figure 11 presents where LPS and Takt can focus on improving flow through individual cycles while also optimising the whole project by identifying critical ‘handoff’ points and achieving the final handover milestone more efficiently and effectively. Identifying the key handoff dates for example, timber frame kit arrives to site, windows install, scaffold drop, internal air test, water and waste connection, power-on, and BCAR submission, the project team can then plan and optimise individual work cycles while also balancing the overall phase or project cycle to ensure there is no unnecessary lag between cycles or no uncomfortable pressure points.

Figure 11. Schematic for phasing of cycles in residential construction project

The management of handoff points and interfaces is a critical component for integrating individual cycles into an overall project duration. Getting the floor slab cast to receive the timber frame kit is a visible early milestone that releases the kit erection cycle to achieve weather tightness. Windows installation then allows the façade and internal completions cycles to proceed independently of one another. The scaffold drop date is a critical milestone as this releases the external completions such as services connections, parking bays, paving and landscaping, and should align with the internal completions cycle to allow effective closeout and handover of the finished units. Project duration then becomes a balance between optimisation of individual cycles and ensuring as best as is feasible that the sum of the optimised cycles leads to a smooth and even flow of work for the contractors while achieving an effective project handover.

A key finding of this study is the need for a knowledgeable and competent Champion that will sustain the planning process once the external person departs the project. The Champion needs foundational Lean awareness as well as an understanding of the concepts and practices of Critical Path Methodology, Last Planner System, and Takt planning. The principal aspect of the role is ensuring standard work relating to the weekly and daily routine to ensure all aspects of Lookahead Planning, Commitment Planning and Learning and Action are implemented.

Numerous challenges to ‘faster’ construction processes were identified and the developer is treating these as ‘improvement opportunities’ across the company. Fragmentation of the sector is an issue that regularly appears in construction research literature and was the root cause of several key challenges that emerged from CS1 and CS2. The mechanical and electrical contractors on the case projects subcontracted the work packages to subcontractors. In some cases, the subcontractors split out houses and batches of apartments or duplexes to smaller subcontractors. Accordingly, crew size could range from two up to 10 crew members. This led to output differences and inflexibility around aligning to discipline-based production schedules as the Takt plan is. Some contractors wanted visibility of up to eight units ready ahead so they could commit a time-based batch of two weeks of work to a particular crew. This didn’t work with the Takt plan that required distinct outputs of two units completed every two days and the next trade ‘wagon’ moving in for the next two days. This issue was helped by the visualisation of the lookahead where the contractors could see where the 2nd fix installation would occur eight days after the 1st fix installation. Once all could trust the reliability of the process it was possible to elicit greater commitment around balanced production rates and alignment with the Takt plan. Contractor’s supervisors strongly resisted repeat visits into units to undertake small tasks for example, connecting a sink waste and tiling a splashback. Generally, this was overcome on-site with some ‘give and take’ conversations with the Last Planners and crew supervisors.

Discussion

PPC is a critical metric when implementing Lean Construction on projects. Progress toward milestones rises and falls with PPC when tasks are made ready in the right sequence and rate. This requires an effective lookahead planning process (Ballard and Tommelein, 2016, pp.5).

CS1 found that traditional planning methodologies were only achieving 53% PPC and this aligns with previous studies that posit less than 60 percent of planned tasks are executed weekly on construction projects (Ballard, et al., 2007; Liu, Ballard, and Ibbs, 2010; Ballard and Tommelein, 2016). Introducing LPS to CS1 resulted in improved PPC which averaged 79% over 15 weeks. This aligns and confirms that improvement accruing from LPS implementation brings positive results to a project as Liu, Ballard, and Ibbs (2010) correlated improved PPC with increased productivity. However, the greatest influence on promoting and sustaining higher PPC accrued from the implementation of Takt to complement the LPS process. Average PPC on CS1 when Takt was introduced was 92% over 20 weeks of the study; this is a 16% increase over using LPS on its own to complement traditional planning methodologies. PPC from CS2 shows continuous improvement from an initial average 81% PPC to a more reliable 93% average PPC for the 25 weeks of Takt complementing the LPS implementation: a 13% increase over LPS on its own. Higher PPC figures and their maintenance at over 90% on both case projects for an extended time reinforces the distinct advantages accruing from the introduction of Takt.

While LPS improves traditional construction planning by introducing a commitment-based process where the work structuring of activities is based on principles applied to time-based planning horizons, Takt goes further by imposing production and factory physics concepts in the planning process. The introduction of concepts like linear process mapping, development of histograms of crew size per activity, focus on small or adjustable work batch sizes, consistent daily management and improvement of the process, allied to the zonal definition of areas based on work density contributes to better construction production flow, and higher PPC, but demands significantly enhanced effort in terms of planning, control, and continuous improvement. The higher PPC on both projects can be attributed to the diligence demanded by the Takt process, as previously found by Schöttle and Nesensohn (2019) and Frandson, Berghede, and Tommelein (2014). This level of attentiveness can lead to frustration for some team members who may not be prepared for the intensity required to keep a Takt plan on track.

Schedule reduction by cycle time

Both case studies showed distinct schedule reduction from Takt complementing LPS. This was especially obvious in blocks of 6 units or more with greater opportunities evident on larger blocks of units. While single or double housing units must go through the entire cycle of trades before achieving milestones, the application of Takt concepts, for example, moving through space in a defined time, meant the layering of cycle times of multiple units enabled faster combined work completions and the contractors always knew where they were going next. It created an environment as close as one could get to a ‘production line’ onsite. The key outcome on both case studies was the quicker dropping of scaffold on blocks allowing external completions to commence earlier and the creation of a ‘buffer’ on internal finishes in case of delivery impacts or resource constraints at joinery completion or decoration stages.

Previous case studies (Frandson, Berghede, and Tommelein, 2013; Frandson and Tommelein, 2016) have focused on cycle time reduction in specific phases of the construction process, for example, dry wall installation and mechanical and electrical installation. Cycle time reduction was again illustrated in the assembly and internal finishing process on CS1 and CS2. An important point highlighted were the exercises on combining activities into single wagons, as used in the Pentagon Renovation project (Horman, et al., 2003), cited in Tommelein and Emdanat (2022, pp.869) - ceiling framing, airtightness, stairs install, and windows and doors install could have been treated as a single ‘wagon’ as, with coordination and sequencing, these trades work well together and deliver a sizeable handoff to the next trades. Identifying key ‘target’ milestones was critical, like getting the block layer to work on the external facades as early as possible. Another single ‘wagon’ with render, fascia, soffit, gutters, and downpipe, and pointing and cleaning, was the prerequisite to releasing the earliest scaffold drop date.

LPS and the Pull Planning process validated the milestones and proved that these were achievable. The introduction of Takt and cycle time and process analysis exercises went further and challenged the traditional perception of activity durations. Last Planners would usually err on the side of caution and allow conservative estimates of durations in the planning sessions. With Takt, a commitment was made that the trial was only experimental, and no supervisor would be criticised if tasks over-ran or finished earlier. It was this experimentation that allowed the progression towards a 40% cycle time reduction of a 25-day duration to a 15-day duration in the timber frame erection to skim coat complete cycle. It was the creation of the psychologically safe environment that allowed the safe experimental space to test and validate this exercise.

While this study and previous research (Frandson, Berghede, and Tommelein, 2013) have presented opportunities in cycle time reduction in selected areas of construction execution, project completion and handover need distinct attention if delivery and management seek effective progression towards completion to milestones. On CS2 much focus was placed on getting the building frames in place to allow façade and roof erection advance to release internal ‘dry’ trade work to commence and progress. The focus was then on the progression of internal apartment and circulation area completion through LPS and Takt planning. While results were positive, it was recognised that insufficient lookahead was being placed on the external works like underground services, water and electrical supply, drainage from the units, access and egress, and landscaping.

Optimisation of the whole project

It is important that a more holistic ‘big picture’ view is taken when applying planning methodologies to construction projects, as shown in Figure 11. Takt has proven what its concepts can bring to both repetitive and non-repetitive work in construction (Tommelein, 2017). However, a broader ‘catch-all’ approach is required to ensure that external works, regulatory documentation, and Building Control Amendment Regulations (BCAR) are also aligned with the scheduled closure dates. CS1 and CS2 showed that the high level and detailed levels of Pull Planning can successfully capture the intent, and then LPS and Takt can guide and control the tasks to timely completion.

Visualisation helped engage the contractors in better planning. Standing back and viewing allocated time against the work required in each zone initiated deeper thinking about how the resources would approach the activities. Conversations emerged with other contractors around getting access into zones late in the afternoon to get materials in the work area for the next morning. Similarly, if some trades were pressed to complete an activity they might seek to share the zone for the first hour of the next day with the trade who had been allocated the zone. As a rule, zone sharing was discouraged as the process needed to respect each trades ownership of the zone and sought discipline around each trade completing their work in the allocated time. It was common to see some trade supervisors at the pull plan wall engaging in micro-planning as they were compiling the next weeks weekly work plans.

The study has shown different planning methodologies can complement one another and lead to better opportunities for achieving success. The master schedule using Primavera P6 is the developer’s planning software of choice and senior schedulers plan the project duration with the Project Directors. This schedule is then used as the reporting tool back to Head Office and Sales for the duration of the project. LPS has been embraced by site management as a methodology that captures Senior Leaderships intent and request and then engages the trades and supply chain to convert the intent into daily and weekly production. Takt concepts has shown the trades that greater production output and efficiency is achievable by application of a disciplined approach towards engaging with the agreed Takt plan. Weekly sessions consistently expose improvement opportunities as presented earlier in Figure 11.

The role of management is critical to effective LPS and Takt implementation. Leadership’s involvement is a vital enabler of change, and this has been identified across Change Management and Lean literature and emerges from this study. Senior leadership advocacy for piloting of LPS and their openness to piloting the concepts of Takt enabled both management team and trade engagement which led to successful outcomes for both case projects. Clarity around roles and responsibilities of head office leadership, site senior management, site middle management, site engineers and trades management and supervision is important to ensure expectations are aligned and planning becomes efficient as opposed to being a burden.

A key observation was that LPS and Takt implementation is a learning process for everyone – over time the process gets better, and members get better at planning and utilising the concepts and ideals. On the second planning session of CS1 apartments Takt and Pull Plan, some trades appeared to be looking for more time to complete the tasks than what they had earlier committed to. This indicates some element of optimism existed during the initial development of the Takt Pull Plan. Examples are erecting partitions and walls was originally 3 days and expanded to 5 days for 3 apartments; First fix mechanical expanded from 3 to 4 days. Electrical 1st fix needed another day as the extent of dead testing, fixing of grounds, and snagging allowance wasn’t sufficient. Installation of ceiling grids along with closing of walls and ceilings increased from 4 to 6 days. This initiated a relook at the overall process analysis and after some exercises it was found that a two-day Takt worked better than the original three-day Takt. This experimentation and rebase-lining required honesty and engagement, and it is on occasions like this on a project that the softer aspects of the contractor’s, developers, and project’s culture comes to the forefront. At other times it would have been easy to blame the complexity of the process and revert to traditional methods. However, the team, at the insistence of the Project Director, saw the value that could accrue and stuck with the replanning process.

Conclusion

This study examined how the discipline, detail, and diligence of Takt complements LPS to deliver an enhanced production-system that betters traditional schedule milestones in residential project delivery.

Takt brought advantageous discipline and rigour to the LPS process. Positive results across both case projects demonstrate the benefits accruing from Takt complementing LPS and Takt. Takt implementation resulted in higher and more consistent PPC (Figure 10) and confirms the approach enhances existing LPS implementations. The key difference between the traditional approach to production planning and control is the increased levels of diligence and discipline required to keep the Takt plan on track, often requiring mindset change for management and trade supervision. It should be noted that the high repetition of similar housing units on both projects allowed for relatively simple implementation of Takt.

Optimisation of the whole project should be the aim of any productivity improvement methodology as focus only on cycle-time reduction of selected elements like internal layouts and finishes can delay attention on façade and external works completions. Reverse planning from handover and occupation must be an integral and ‘live’ aspect of steering a project towards completion. Attention to the softer aspects of creating a psychologically safe environment for implementation of the mechanics of LPS and Takt is a critical enabler of successful implementation.

Technical knowledge of Takt is well understood however, there is an opportunity for further research in the adoption of Takt planning in wider construction delivery. The rigour and discipline required for effective Takt implementation calls for different behaviours as exhibited by LPS users – future research should examine how ideal behaviours for successful LPS and Takt integration can be further developed.

References

Abdelhamid, T., 2004. The self-destruction and renewal of lean construction theory: A prediction from Boyd’s Theory. In: Proceedings of the 12th Annual Conference of the International Group for Lean Construction, Helsingør, Denmark, 3-5 August. pp.1-19.

AlSehaimi, A., Koskela, L. and Tzortzopoulos, P., 2013. Need for alternative research approaches in construction management: Case of delay studies. Journal of Management in Engineering, [e-journal] 29, pp.407-13. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000148

Ansar, A., Flyvbjerg, B., Budzier, A. and Lunn, D., 2014. Should we build more large dams? The actual costs of hydropower megaproject development. Energy Policy, [e-journal] 69, pp.43-56. https://doi.org/10.1016/j.enpol.2013.10.069

Ballard, G. and Howell, G., 1997. Implementing lean construction: improving downstream performance. In: Luis Alarcon, ed. Lean Construction. Oxford and New York: Taylor and Francis. pp.111-25.

Ballard, G. and Howell, G., 1998. What kind of production is construction. In: Proceedings of the 6th Annual Conference of the International Group for Lean Construction, 13-15 August, Guaruja, Brazil, pp.13-15.

Ballard, G., 2000. The last planner system of production control. PhD. The University of Birmingham.

Ballard, G. and Howell, G., 2003. An Update on Last Planner. In: Proceedings of the 11th Annual Conference of the International Group for Lean Construction, 22-24 July 2003, Blacksburg, Virginia, USA.

Ballard, G., Kim, Y., Jang, J. and Liu, M., 2007. Roadmap for lean implementation at the project level - CII Research Report 234-11. Texas, USA: The Construction Industry Institute.

Ballard, G. and Tommelein, I., 2016. Current Process Benchmark for the Last Planner® System. Lean Construction Journal, [e-journal] pp.57-89. https://doi.org/10.60164/47e7h7a1b

Ballard, G., 2020., The last planner system. In: Patricia Tzortzopoulos, Mike Kagioglou and Lauri Koskela, eds. [e-book] Lean Construction: Core Concepts and New Ideas. London: Routledge. pp.45-53. https://doi.org/10.1201/9780429203732-3

Ballard, G., Vaagen, H., Kay, W., Stevens, B. and Pereira, M., 2020. Extending the Last Planner System® to the Entire Project. Lean Construction Journal, [e-journal] pp.42-77. Available at: https://leanconstruction.org/wp-content/uploads/2022/08/LCJ_19_019.pdf.

Ballard, G. and Tommelein, I., 2021. 2020 Current Process Benchmark for the Last Planner® System of Project Planning and Control. Lean Construction Journal, [e-journal] pp.53-155. https://doi.org/10.60164/47e7h7a1b

Barbosa, F., Woetzel, J. and Mischke, J., Ribeirinho, M.J., Sridhar, M., Parsons, M., Bertram, N. and Brown, S., 2017. Reinventing Construction: A Route of Higher Productivity. McKinsey Global Institute.

Braun, V. and Clarke, V., 2006. Using thematic analysis in psychology. Qualitative research in psychology, [e-journal] 3(2), pp.77-101. https://doi.org/10.1191/1478088706qp063oa

Creswell, J., 2009. Mapping the field of mixed methods research. Journal of mixed methods research, [e-journal] 3(2), pp.95-108. https://doi.org/10.1177/1558689808330883

Construction Industry Institute., 2015. CII 2015 Annual report, Available at: CII - Publication-Details (construction-institute.org), [Accessed 22 June 2023].

Daniel, E. and Pasquire, C., 2017. Last Planner System Path Clearing Approach. Nottingham, UK: Nottingham Trent University Publications.

Daniel, E., Pasquire, C., Chinyio, E., Oloke, D. and Suresh, S., 2020. Development of Collaboration in Planning: What Can Construction Project Management Learn from Other Fields? In: Proceedings of the 28th Annual Conference of the International Group for Lean Construction, Berkeley, California. pp.289-300. https://doi.org/10.24928/2020/0002

Dlouhy, J., Binninger, M., Oprach, S., and Haghsheno, S., 2016. Three-level method of Takt planning and Takt control–A new approach for designing production systems in construction. In: Proceedings of the 24th Annual Conference of the International Group for Lean Construction. Boston, USA. pp.13-22.

Flyvbjerg, B., Bruzelius, N. and Rothengatter, W., 2003. Megaprojects and Risk: An anatomy of ambition. [e-book] Cambridge University Press. https://doi.org/10.1017/CBO9781107050891

Frandson, A., Berghede, K. and Tommelein, I., 2013. Takt time planning for construction of exterior cladding. In: Proceedings of the 21st Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil. pp.21-2.

Frandson, A., Berghede, K. and Tommelein, I., 2014. Takt-time planning and the last planner. In: Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway. pp.571-80.

Frandson, A. and Tommelein, I., 2016. Takt Time Planning of Interiors on a Pre-Cast Hospital Project. In: Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, Massachusetts. pp.143-52.

Frandson, A., 2019. Takt time planning as a work structuring method to improve construction workflow. PhD. University of California, Berkeley.

Galloway, P., 2006. Survey of the construction industry relative to the use of CPM scheduling for construction projects. Journal of Construction Engineering and Management, [e-journal] 132(7), pp.697–711. https://doi.org/10.1061/(ASCE)0733-9364(2006)132:7(697)

Green, S., Kao, C. and Larsen, G., 2010. Contextualist research: Iterating between methods while following an empirically grounded approach. Journal of Construction Engineering and Management, [e-journal] 136(1), pp.117-26. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000027

Haghsheno, S., Binninger, M., Dlouhy, J. and Sterlike, S., 2016. History and Theoretical Foundations of Takt Planning and Takt Control. In: Proceedings of the 24th Annual Conference of the International Group for Lean Construction. Boston, Massachusetts, USA. pp.53-62. https://doi.org/10.24928/2017/0297

Hamzeh, F., 2009. Improving Construction Workflow – The Role of Production Planning and Control. Ph.D. University of California, Berkeley, U.S.A.

Hamzeh, F., Ballard, G. and Tommelein, I., 2009. Is the Last Planner System applicable to design?. In: Proceedings of the 17th annual conference of the International Group for Lean Construction, Taipei, Taiwan, pp.167-76.

Hamzeh, F., Kallassy, J., Lahoud, M. and Azar, R., 2016. The first extensive implementation of lean and LPS in Lebanon: results and reflections. In: Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, USA. pp.33-42.

Hopp, W.J. and Spearman, M., 2011. Factory physics. Illinois, USA: Waveland Press Inc.

Horman, M., Messner, J., Riley, D. and Pulaski, M., 2003. Using buffers to manage production: A case study of the Pentagon renovation project. In: Proceedings of the 11th Annual Conference of the International Group for Lean Construction, 22-24 July 2003, Blacksburg, Virginia.

Howell, G., Ballard, G., and Tommelein, I., 2010. Construction engineering—Reinvigorating the discipline. Journal of Construction Engineering and Management, [e-journal] 137(10), pp.740-44. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000276

Hwang, B., Thomas, S., Haas, C. and Caldas, C., 2009. Measuring the impact of rework on construction cost performance. Journal of construction engineering and management, [e-journal] 135(3). pp.187-98. https://doi.org/10.1061/(ASCE)0733-9364(2009)135:3(187)

Hwang, B.-O. and Yang, S., 2014. Rework and schedule performance. A profile of incidence, impact, causes and solutions. Engineering, Construction and Architectural Management, [e-journal] 21, pp.190-204. https://doi.org/10.1108/ECAM-10-2012-0101

Koskela, L., 2000. An exploration towards a production theory and its application to construction. Doctor of Technology. VTT Technical Research Centre of Finland.

Koskela, L. and Howell, G., 2001. Reforming project management: the role of planning, execution and controlling. In: Proceedings of the 9th Annual Conference of the International Group for Lean Construction, Singapore. https://iglc.net/Papers/Details/147

Koskela, L. and Howell, G., 2002. The underlying theory of project management is obsolete. In: Proceedings of the PMI Research Conference, pp.293-302. https://doi.org/10.1109/EMR.2008.4534317

Lehtovaara, J., Seppänen, O., Peltokorpi, A., Kujansuu, P. and Grönvall, M., 2021. How Takt production contributes to construction production flow: a theoretical model. Construction Management and Economics, [e-journal] 39(1), pp.73-95. https://doi.org/10.1080/01446193.2020.1824295

Liu, M., Ballard, G. and Ibbs, W., 2010. Workflow Variation and Labor Productivity: Case Study. Journal of Management in Engineering, [e-journal] 27(4), pp.236-42. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000056

Liu, J., Yi, Y., Wang, X., 2020. Exploring factors influencing construction waste reduction: A structural equation modeling approach. Journal of Cleaner Production, [e-journal] 276, pp.123185. https://doi.org/10.1016/j.jclepro.2020.123185

Love, P.E., Edwards, D.J., Watson, H. and Davis, P., 2010. Rework in civil infrastructure projects: Determination of cost predictors. Journal of Construction Engineering and Management, [e-journal] 136(3), pp.275-82. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000136

Mossman, A., 2019. Last Planner: 5 + 1 Crucial and Collaborative Conversations for Predictable Project Production Planning. The Change Business Ltd. Available at: https://www.researchgate.net/publication/321804312_Last_Planner_5_1_crucial_collaborative_conversations_for_predictable_design_construction_delivery_Dec_2017 [Accessed 09 July 2023].

Oakland, J. and Marosszeky, M., 2017. Total Construction Management: Lean Quality in Construction Project Delivery. [e-book] London: Taylor & Francis. https://doi.org/10.4324/9781315694351

Oberlender, G., 2000. Project management for engineering and construction, Boston: McGraw-Hill.

Paz, J.C., Rozenboim, D., Cuadros, Á., Cano, S. and Escobar, J.W., 2018. A Simulation-Based Scheduling Methodology for Construction Projects Considering the Potential Impacts of Delay Risks. Construction Economics and Building, [e-journal] 18(2), pp.41-69. https://doi.org/10.5130/AJCEB.v18i2.5842

Power, W. and Taylor, D., 2019. Last Planner® System and Percent Plan Complete: An Examination of Trade Contractor Performance. Lean Construction Journal, [e-journal] pp.131-46. https://doi.org/10.24928/2019/0164

Rivera, A., Le, N., Kashiwagi, J. and Kashiwagi, D., 2016. Identifying the global performance of the construction industry. Journal for the Advancement of Performance Information & Value, [e-journal] 8(2), pp.7-19. https://doi.org/10.37265/japiv.v8i2.61

Sarhan, S., Pasquire, C., and King, A., 2017. The concept of Institutional Waste within the Construction industry: A potential theoretical framework. Lean Construction Journal, [e-journal] pp.12-24.

Saunders, M., Lewis, P. and Thornhill, A., 2016. Research methods for business students. 7th ed. New York: Pearson Education.

Schöttle, A., and Nesensohn, C., 2019. The Beauty of a Phase-overlapping Last Planner System with incorporated Takt. In: Proceedings of the 27th Annual Conference of the International. Group for Lean Construction, Dublin, Ireland. pp.441–50. https://doi.org/10.24928/2018/0247

Stake, R., 1995. Case Study Research. Thousand Oaks, CA: Sage.

Tommelein, I., 2017. Collaborative Takt time planning of non-repetitive work. In: Proceedings of the 25th Annual Conference of the International Group for Lean Construction. Heraklion, Greece, pp.745-52. https://doi.org/10.24928/2017/0271

Tommelein, I. and Emdanat, S., 2022. Takt Planning: An Enabler for Lean Construction. In: Proceedings of the 30th Annual Conference of the International Group for Lean Construction, Edmonton, Canada, pp.866-77. https://doi.org/10.24928/2022/0198

Tommelein, I. and Lerche, J., 2023. Comparison of Takt Planning Methods Used on Projects of Different Types. In: Proceedings of the 31st Annual Conference of the International Group for Lean Construction, Lille, France, pp.1605-16. https://doi.org/10.24928/2023/0255

Weinheimer, N., Schmalz, S. and Müller, D. 2017. Green Building and Lean Management: Synergies and Conflicts. In: Proceedings of the 25th annual conference of the International Group for Lean Construction, Heraklion, Greece, pp.911-18. https://doi.org/10.24928/2017/0242

Yin. R., 1993. Applications of Case Study Research. Beverly Hills, CA: Sage Publishing.