Construction Economics and Building

Vol. 24, No. 4/5

December 2024

RESEARCH ARTICLE

Kanban Applied to Construction: A Literature Review

Joaquín Fuentes-del-Burgo1,*, Juan Pedro Ruiz Fernández2,

Elena Navarro-Astor2

1 Universidad de Castilla-La Mancha, Cuenca, Spain, joaquin.fuentes@uclm.es

2 Universidad de Castilla-La Mancha, Cuenca, Spain, juanpedro.ruiz@uclm.es

3 Universitat Politècnica de València, Valencia, Spain, enavarro@omp.upv.es

Corresponding author: Joaquín Fuentes del Burgo. Escuela Politécnica de Cuenca. Campus Universitario. 16071 Cuenca (Spain), joaquin.fuentes@uclm.es

DOI: https://doi.org/10.5130/AJCEB.v24i4/5.8642

Article History: Received 22/05/2023; Revised 29/09/2023; Accepted 28/04/2024; Published 23/12/2024

Citation: Fuentes-del-Burgo, J., Fernández, J. P. R., Navarro-Astor, E. 2024. Kanban Applied to Construction: A Literature Review. Construction Economics and Building, 24:4/5, 43–57. https://doi.org/10.5130/AJCEB.v24i4/5.8642

Abstract

Kanban is a process management system originally developed in the automotive industry that is migrating to other fields such as construction. This article provides a literature review of 53 international scientific contributions that focus on the application of Kanban in the construction sector. The content has been qualitatively analysed using ATLAS.ti 8.1 software and interpretative synthesis applied to summarise relevant findings. Kanban has been used for supply chain management, Just In Time (JIT) implementation in construction, and the Last Planner® System (LPS) for work management and coordination. In addition, we have detected a progressive evolution to E-Kanban systems and their application in Building Information Management (BIM) environments, as well as the development of new software applications and methods. Kanban’s flexibility and its value in terms of improving the performance of construction sites is highlighted. Future research is suggested to explore the implementation of this system in the European and Spanish construction sector.

Keywords

BIM; Construction Industry; E-Kanban; Kanban; Last Planner System

Introduction

The productivity of the construction industry is lower than that of other industries (Pheng, Shang and Peter, 2016; Campoy-Muñoz and Delgado, 2020). Its characteristics include its labour-intensive nature (Ko, Wang and Kuo, 2011), its fragmentation (Pheng, Shang and Peter, 2016), and a traditional business organisation and management approach (Heravi and Rashid, 2018), which, according to Si, et al. (2021), presents a number of shortcomings.

In addition, on-site production, the unique nature of projects with designs that involve assemblies of varying specifications, and the complexity, derived from multi-organisational timing, unique dynamics and a high degree of regulation, differentiate the construction sector from manufacturing industry (Paez, et al., 2005; Salem, et al., 2006). If these characteristics are combined with inclement weather, a lack of equipment, a shortage of labour and a low level of productivity, errors, reworking, a lack of quality, safety risks, a lack of understanding of the project and processes involved, and delays in supplier deliveries, the result is that these projects are subject to a great deal of uncertainty (Salem, et al., 2006; Guo, et al., 2013; Tezel and Aziz, 2017; Si, et al., 2021; Xing, et al., 2021). The effects include cost overruns, significant wastage of time and materials, and the inability to meet schedule milestones (Guo, et al., 2013; Mahfuth, et al., 2020; Schimanski, et al., 2021).

Any construction project is usually undertaken by a number of contractors working for a general contractor (Straçusser, 2015), as well as in a dynamic and usually crowded environment, in a sequence based on the pre-planning of actions (Sacks, Radosavljevic and Barak, 2010; Safa, et al., 2022). It also requires a wide spectrum of workers, including carpenters, masons, plumbers, and so on, and a growing diversity of experts, such as architects, building engineers, structural engineers, and mechanical engineers (Demir, et al., 2012). In this context, effectively managing production by coordinating and directing the work of a large number of professionals and work teams is a complex task (Sacks, Radosavljevic and Barak, 2010; Demir, et al., 2012).

Today, construction companies are facing increased competition and clients are demanding lower costs, higher quality, reduced execution times, and a more reliable schedule (Boateng, 2019). These demands are forcing them to rethink their production methods and systems to increase value for their customers, boost their productivity and consider their sales strategies (Perroni de Burgos and Bastos Costa, 2012; Ekanayake and Sandanayake, 2017).

The construction industry is, therefore, attempting to improve its performance by applying practices from the manufacturing industry (Goh and Goh, 2019), such as the Lean philosophy. There is a trend towards integrating this into construction projects by developing methods and applications to improve performance-related parameters such as time, profit, productivity and workflow (Heravi and Rashid, 2018; Tezel, et al., 2020; Francis and Thomas, 2020).

The idea of Lean Construction (LC) was introduced in the 1990s by L. Koskela, as a change to the conventional approach to the industry, and it received a great deal of attention from companies in the sector (Xing, et al., 2021; Francis and Thomas, 2020). It is a construction management style that minimises waste, time and effort, by reducing variability; improving quality, reliability and productivity; increasing the workflow and overall efficiency in terms of project delivery; and eventually leading to reduced costs and improved profits (Guo, et al., 2013; Xing, et al., 2021; Francis and Thomas, 2020).

In their literature review, Babalola Ibem and Ezema (2019) identified 32 Lean practices applied to construction projects, classified into four categories: design and engineering; planning and control; construction and construction management; and health and safety management. The most commonly used was the Last Planner® System (LPS) developed by Ballard and Howell, together with the Just In Time (JIT) method and the Kanban system (Pellicer, et al., 2015; Xing, et al., 2021).

This paper presents a literature review of how the Kanban system has been applied in the construction sector. The method, results and conclusions are presented below.

Method

Literature reviews facilitate the investigation of different approaches to the topic under study (Lage and Godinho, 2010), identifying inputs and contributing new evidence (Tranfield, Denyer and Smart, 2003), to provide an updated view of existing knowledge (Garcés, 2020).

They also allow the integration of findings and perspectives from different empirical works (Snyder, 2019), facilitating a synthesis that helps to construct new conceptual models (Snyder, 2019), as well as enabling other researchers to consult the cited bibliographic sources (Gómez-Luna, et al., 2014).

The article presents an overview of the literature on how Kanban and related techniques have been applied in the construction sector, collating the information in a structured way to add value by describing the application of this Lean technique (Van Wee and Banister, 2016).

The research protocol is a synthesis of several suggested standards and guidelines for literature reviews (Snyder, 2019), comprising the following steps (Nightingale, 2009; Vieira de Carvalho, Denis Granja and Gomes da Silva, 2017; Snyder, 2019; Caldera, Ryley and Zatyko, 2020; Garcés, 2020):

1. Define the objective of the review and the research questions;

2. Select the databases;

3. Define keywords and search criteria;

4. Establish practical inclusion and exclusion criteria;

5. Conduct the search for articles;

6. Review those selected;

7. Apply the snowball sampling technique;

8. Analyse; and

9. Report the results.

The objective is to learn how the Kanban system, developed in the automotive industry, has been applied in the construction sector. To achieve this, the following research questions were posed, identified by the letters RQ, followed by a number (Torres-Carrión, et al., 2018):

• RQ-1: What are the characteristics of the Kanban system?

• RQ-2: How has the Kanban system been applied in the construction sector?

The databases Web of Science, Scopus, ScienceDirect and ASCE Library were selected (Rother, 2007; Van Wee and Banister, 2016; Vieira de Carvalho, Denis Granja and Gomes da Silva, 2017; Caldera, Ryley and Zatyko, 2020), complemented by the Google Scholar meta-search engine (Van Wee and Banister, 2016).

The search was carried out using keywords and search equations formed by keywords together with logical operators, established according to the subject (Gómez-Luna, et al., 2014; Tranfield, Denyer and Smart, 2003). The terms used were the following: “Kanban” AND “Construction,” “Kanban” AND “Construction Management;” “Kanban” AND “Project Management” and ““Kanban” AND “BIM.”

Inclusion and exclusion criteria were applied based on the content of the title, abstract and keywords (Hepplestone, et al., 2011; Caldera, Ryley and Zatyko, 2020). We included papers from blind-reviewed conferences because these allow us to know the state-of-the-art (Rivas Tovar, 2011; Sánchez Ruiz, Blanco Rojo and Pérez-Labajos, 2013). The exclusion criteria were: (1) The article was outside the scope of the construction industry; (2) it was not written in English or Spanish; or (3) it did not address the Kanban system and the construction field together (Vieira et al., 2017).

A total number of 63 documents met the inclusion criteria; however, after analysis, only 42 presented content related to the research objective.

In the analysis phase, the full articles were read and independent judgements were made with the most useful papers for the topic being selected (Gómez-Luna, et al., 2014; Wnuk and Garrepalli, 2018). In addition, the snowball sampling technique was applied to obtain new references and complement the sample (Hepplestone, et al., 2011; Vieira de Carvalho, Denis Granja and Gomes da Silva, 2017; Garcés, 2020) with papers directly related to the aspects most relevant to the research objective (Gómez-Luna, et al. ,2014).

According to Wohlin (2014), this technique refers to the use of an article’s reference list or citations to identify additional articles to include in the literature review. It can be applied in two ways: forward snowballing involves finding citations for an article (Van Wee and Banister, 2016); while backward snowballing involves using the article’s reference list to identify new papers to include (Wohlin, 2014; Wnuk and Garrepalli, 2018). In this study we used backward snowballing, selecting articles that met the inclusion criteria (Wohlin, 2014). Hence, 11 more references were added in the analysis phase.

The articles were analysed qualitatively using the ATLAS.ti 8.1 software, by open coding the content describing the characteristics and practices related to the Kanban system (Lappi, et al., 2018). An interpretive synthesis was applied during the reading of the articles, and narrative was used to summarise the methods and key findings (Greenhalgh, et al., 2009).

Results and discussion

The Kanban System

Kanban is a subsystem of the Toyota Production System in the automotive industry (Jang and Kim, 2007; Lage and Godinho, 2010). “Kanban” is a Japanese term meaning “visual card” or “sign” (Jang and Kim, 2007; Kanai, et al., 2021) and it acts as a work order that must be present for a particular task to start (Jang and Kim, 2007). It is used to provide information that regulates production, so that each process on a production line extracts only the quantity and type of components it requires, producing what is needed, when it is needed (Boateng, 2019; Tapase, 2019).

To help the reader, “Kanban” written here with a capital letter refers to the system and “kanban”, with a lower case letter, refers to the cards.

Kanban management is a tool for transmitting information and/or recording information. It can involve a board or a card, which has the basic function of recording production information, passing on work instructions and avoiding waste (Bi and Jia, 2016).

The original Kanban system was a JIT control system, but it does not have to be applied only to JIT production (Zeng, et al., 2019); for example, it also allows information to be passed between members of a project team (Jang and Kim, 2007). The system involves the use of an inventory control card or a sign for inventory at the project site. This ensures an effective inventory and proper record keeping in the construction project (Babalola, Ibem and Ezema, 2019).

In a Lean manufacturing environment, Kanban is a visual control system that acts as a material flow mechanism (Khalfan, et al., 2008; Lage and Godinho, 2010). The Kanban strategy has five main tasks: order placement, product ordering, product procurement, shipping and replenishment (Kanai, et al., 2021).

The Kanban system is designed to be a scheduling system that controls the flow of production in real time, establishing what to produce, when to produce it and how much to produce (Pheng, Shang and Peter, 2016; Zeng, et al., 2019). Its application allows inventory levels to be controlled and reduced; the production and supply of components and, in some cases, raw materials to be controlled; overproduction to be eliminated; flexibility to be increased; continuous flow to be created; and costs to be reduced by eliminating waste (Khalfan, et al., 2008; Lage and Godinho, 2010; Ko, Wang and Kuo, 2011).

The system is highly adaptable, as demonstrated by its application to the industrial sector (El Abbadi, et al., 2018), software engineering (Ahmad, et al., 2018) and the construction industry (Arbulu, Ballard and Harper, 2003). In industries associated with the construction sector, Ahmad, et al. (2018) looked at how implementing a JIT and Kanban system could improve performance in the production of industrialised pre-cast concrete building system components, and Lu, Olofsson and Stehn (2011) studied the development of a production system for prefabricated wooden houses.

As mentioned, the Kanban system is linked to the Lean concept of JIT (Salem, et al., 2006), which considers that inventories do not add value and should be treated as waste (Paez, et al., 2005). The method for achieving JIT production is based on a pull system, in other words, a system that always adjusts production to demand (Si, et al., 2021).

The JIT production organisation system allows for the rapid delivery of materials, information, or any element required by a project to the point of use (Babalola, Ibem and Ezema, 2019). JIT is used in the LC with positive results (Guo, et al., 2013; Goh and Goh, 2019). By using a Kanban system, the production process is transformed into a pull system. Kanban also allows the transmission of information, material usage instructions and production instructions, helping to control the flow of information and material (Guo, et al., 2013).

One of the goals of JIT is to ensure production levelling so that a fluctuation in demand can be met by the correct sequence of products with minimum batch sizes (Salem, et al., 2006). Determining the appropriate Kanban size and storage level therefore requires substantial planning, as specifying incorrect values could result in the over- or under-delivery of materials (Goh and Goh, 2019).

Three categories of cards, or kanban, are used in the Toyota Production System (TPS) (Ko and Kuo, 2018):

• Production: used between the finished goods warehouse and the production line to initiate production in the system.

• Material withdrawal: used by the workers to retrieve the parts they need from the warehouse. The item and the corresponding number of pieces to be withdrawn are recorded.

• Signal and management: here the Kanban is a static board placed in the production area on which two types of cards are placed: one with information for the workers or project participants, and the other showing management data.

According to Qiaolan and Bin (2021), a Kanban system applied to construction cannot completely replicate the classification configuration and operation mechanism of the Kanban used in industrial production management. It must combine with construction management features to develop a system that considers the architectural characteristics (Qiaolan and Bin, 2021).

Other types of cards were found in the review, with functions similar to the categories established in the TPS, depending on how the Kanban system is implemented. For example, Arbulu, Ballard and Harper (2003) use a supply kanban, which transmits a material replenishment signal to external suppliers. It can also be used to communicate information on safety aspects of construction work (Tezel and Aziz, 2017).

Tapler (2014) includes the kanban cards that are prepared and delivered to site managers, including during the project plan creation phase, when the detailed scheduling of operations takes place. He also proposes using a kanban card as a tool to record completed work (Tapler, 2014). At a conceptual level, the kanban signal itself does not necessarily signify a card; it could be a flag or other object that has an agreed meaning (Tapler, 2014).

Jang and Kim (2007) propose using Kanban as a work order to manage the production process and as a tool to control the construction process, where work should not start without the appropriate kanban. These cards have three functions (Jang and Kim, 2007):

• The ordering kanban. Sent by a controller from the office to the engineer responsible for the on-site work, including: type of work, work identification number, person responsible, quantity, location, start and completion dates, resources required, unresolved constraints, prerequisites and follow-up work, special requests for the work, and safety information.

• The receipt kanban (linked to the ordering kanban). Sent by the on-site engineer to the work controller in the office, it includes the same information as above, plus a box to verify the work completed, plus another for the actual date of completion and the reasons why the work was not completed on time. It is used to calculate performance measurements for production processes and progress payments.

• The auxiliary kanban is used to include additional work and delays. It is issued based on the weekly work plan, but is sometimes issued for additional work commissioned by the owner. These are necessary as no work can be started without the appropriate kanban.

Perroni de Burgos and Bastos Costa (2012) use two types of kanban or cards in the construction phase of buildings. One for the production and transport of the materials produced on site, such as cement mortar, and one for the transport of materials not produced on site, such as bricks and ceramic tiles (Perroni de Burgos and Bastos Costa, 2012). The kanban card must contain the necessary data on quantity, time and place of delivery, providing the necessary information on the product or material to produce and/or transport, thus avoiding overproduction (Perroni de Burgos and Bastos Costa, 2012).

Other ways of adapting and using the Kanban system have also been described (Jang and Kim, 2007; Moreira Barreto and Heineck, 2012; Valente, Brandalise and Formoso, 2019). For example, applying it to manage the flow of materials on construction sites (Tapler, 2014; Moreira Barreto and Heineck, 2012), or to implement a continuous flow in formwork construction, reducing the mould inventory (Ko and Kuo, 2018). Several papers describe its use as a visual management system for handling information on a construction site (Tezel, et al., 2015; Valente, Brandalise and Formoso, 2019).

Arbulu, Ballard and Harper (2003) outline the following strategy: (1) the materials must be transported through the supply network as needed to the work site; (2) the materials, in adequate quantities, must arrive on time at the right place; (3) the supply network delivers the best value to the customer; (4) the necessary measures are taken to minimise vehicle movements on the site; and (5) all necessary measures are implemented to increase the reliability of the on-site work flow (Arbulu, Ballard and Harper, 2003).

When implementing a Kanban system in the construction supply chain, it is recommended that the periodic Kanban batch size is determined based on the short-term demand forecast (Zeng, et al., 2019). This batch size is determined by the flow of extracted material (Zeng, et al., 2019), and affected by supplier capacity and the availability of suitable vehicles to transport the material to the construction site (Paez, et al., 2005).

In addition, to implement a Kanban approach, there must be adequate storage space on the construction site (Zeng, et al., 2019). Once the initial batches of material arrive on site, their consumption can be recorded in real time, and discrete demand can be reported using kanban cards (Zeng, et al., 2019).

The Kanban System and Last Planner® System (LPS)

Some studies have indicated that the Kanban system is related to LPS (Paez, et al., 2005; Rybkowski, 2010; Modrich and Cousins, 2017; Schimanski, et al., 2019; Xing, et al., 2021). LPS delivers a planning, monitoring and control system that follows Lean principles, such as pull planning (similar to Kanban), just-in-time delivery, and Value Stream Mapping (VSM) (Sivaganesh and Ratnayake, 2018).

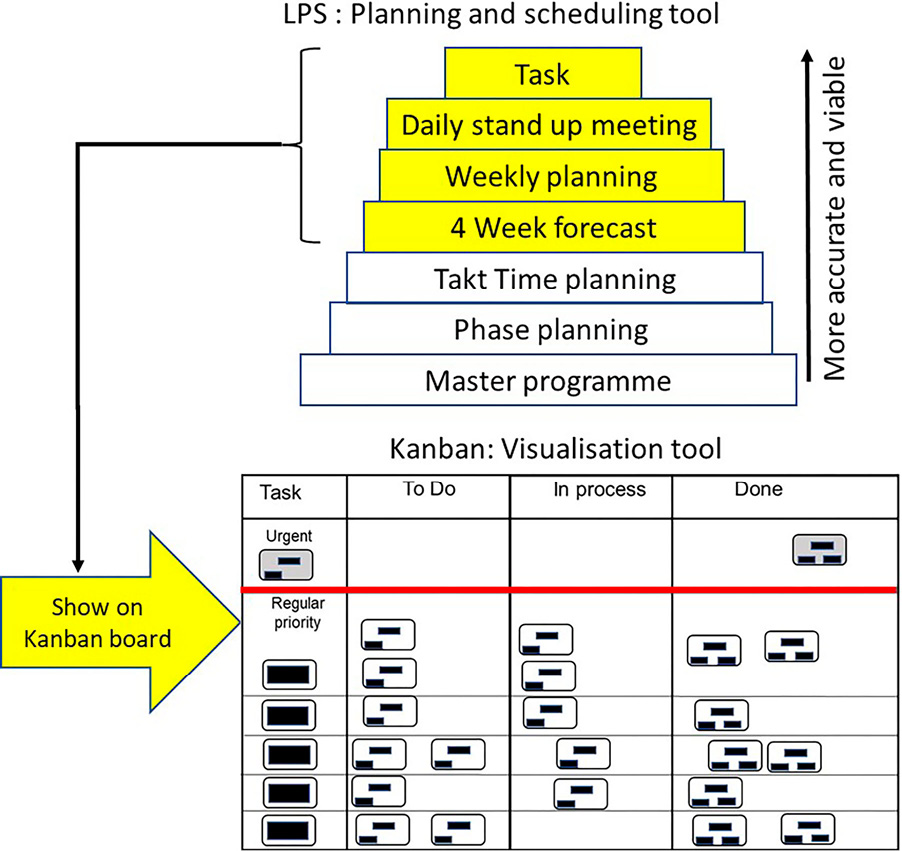

In their case study, Xing, et al. (2021), report that LPS was used for planning and scheduling, while Kanban was used as a visual tool to display detailed weekly and daily schedules (Figure 1). Through the information provided by Kanban, task specifications and sequences are clearly visible to the workers and/or the ultimate planners (Schimanski, et al., 2019). The objective of using both techniques is to reduce variation and improve project workflow (Xing, et al., 2021).

Figure 1. Components of LPS and Kanban system, and the relationships between them (Source: Xing, et al., 2021. Own elaboration)

In Figure 1, from the Takt Time planning, using a Kanban board, the 4-week forecast, the weekly plan and the daily meetings are interconnected (Xing, et al., 2021). Some authors propose a 6-week forecasting interval (Jang and Kim, 2007). Advance and weekly work plans inform subcontractors about the activities to be completed, therefore functioning like kanban cards in manufacturing (Paez, et al., 2005).

The weekly meeting allows the progress made in the preceding week to be analysed and the plan for the following week to be presented, classifying each activity according to different disciplines, such as civil engineering, mechanics, electricity, plumbing, and so on. In this way, the LPS principle is applied: the construction plans should be established by the construction staff as the ultimate planners, thereby ensuring their involvement in the generation of the project schedule (Xing, et al., 2021).

The stand-up meeting, or stum, is a fundamental element in the operation of the LPS and Kanban systems, as it strengthens the communication between managers and construction personnel at the operational level (Xing, et al., 2021). It should take place in a large room located in a site hut or office, with sufficient space to accommodate the participants, the so-called “Big Room” or Obeya in Japanese (Erazo-Rondinel, Vila-Comun and Diaz, 2020). The Kanban board should be placed on one or more of its walls to facilitate viewing and collaborative planning (Pellicer, et al., 2015; Pons Achell and Rubio Pérez, 2019; Erazo-Rondinel, Vila-Comun and Diaz, 2020).

The members of the Lean Construction Management group should meet at the end of each day to review the status of the day’s activities and discuss any issues identified on site. Problems to be solved within the week are recorded by means of sticky notes attached to the Kanban moving time chart. Different coloured post-it notes can be associated with the various disciplines (Xing, et al., 2021).

E-Kanban

Industry 4.0 is based, among other things, on cybernetic systems, sensor systems, and the Internet of Things (IoT), resulting in an evolution toward electronic production systems (Boca and Isitan, 2021). The effect on the traditional Kanban card system has been its evolution towards electronic Kanban production systems (E-Kanban) taking advantage of the new technologies provided by the industrial revolutions (Boca and Isitan, 2021). Hence, E-Kanban is a variation of kanban cards with only one modification, the physical signal is replaced by electronic ones (Lage and Godinho, 2010; Gayakwad and Attarde, 2022). The production system that controls the flow of material between workstations uses an electronic signal (Boca and Isitan, 2021).

E-Kanban can also store the kanban card information and use the user interface to display its information. It does not change the theory of traditional kanban, but does improve its accuracy and implementation speed (Guo, et al., 2013).

There are various types of E-Kanban systems. One of these is applied in the design phase for project coordination (Modrich and Cousins, 2017). The tool displays each designer’s tasks in several horizontal columns or rows. The Kanban board is digital, such as those provided by a number of different software or online programmes, like Trello, LeanKit, KanbanFlow and JIRA (Modrich and Cousins, 2017). Digital Kanban boards have the benefit of attaching information, knowledge or decisions to the kanban, which can be archived and accessed later, without losing the knowledge gained during the design (Modrich and Cousins, 2017). A digital Kanban board provides the project manager with a variety of metrics to help interpret and manage the flow of team activities (Modrich and Cousins, 2017).

E-Kanban approaches applied to supply chain management can comprise electronic signals obtained through barcode scanning, or the use of RFID systems, which allow real-time information to be sent to the supplier (Son, et al., 2010; Goh and Goh, 2019; Gayakwad and Attarde, 2022). To implement this system, an agreement must be reached with the manufacturer or supplier, who will send the material or equipment to the construction site based on the actual on-site consumption (Barkmeyer and Kulvatunyou, 2007).

E-Kanban can also be implemented through mobile apps, using smartphones and apps that allow kanban operations to be implemented at construction sites, although these typically lack the necessary Information Technology (IT) system infrastructure needed to manage an online inventory (Tapler, 2014).

Guo, et al. (2013) propose using several types of E-kanban. The transmission system sends information between different locations, for example, the material requisitioner sends order information to the material supplier; the production system transfers information between different related workplaces; the temporary one transmits information between different locations or workplaces in case of emergency. The feedback kanban facilitates the feedback of information between the above E-kanban systems, considering the circumstances prevailing on the construction site (Guo, et al., 2013).

E-Kanban is often compared to physical cards (Guo, et al., 2013; Tapler, 2014), but has advantages such as: increasing the transparency and visibility of the system (Goh and Goh, 2019; Boca and Isitan, 2021); improving the traceability of movements in the system and facilitating real-time information gathering and feedback (Guo, et al., 2013; Boca and Isitan, 2021); managing a larger number of materials (Boca and Isitan, 2021); helping to improve dealings with suppliers and evaluating supplier performance (Lage and Godinho, 2010); eliminating the problem of distance between production operations (Lage and Godinho, 2010); reducing the waiting time in the replenishment process (Tapler, 2014); improving production efficiency and quality (Guo, et al., 2013); facilitating the use of computers or the cloud to increase the amount of information stored in the database (Guo, et al., 2013; Tapler, 2014); minimising errors in terms of information sent and avoiding card losses (Tapler, 2014); and reducing the amount of company paperwork (Lage and Godinho, 2010).

The disadvantages of implementing E-Kanban include the need for an IT infrastructure, as well as the impossibility of physically viewing the board with the cards (Tapler, 2014).

Kanban and BIM

The digitalisation of industrial production through the Industry 4.0 concept may be the key to increasing productivity in construction. Building Information Modelling (BIM), as a means of digitally representing the physical and functional characteristics of buildings and the data provided in this way, represents the initial transposition of Industry 4.0 into the construction field (Schimanski, et al., 2019). BIM has become an essential approach for making project processes more fluid, transparent and integrated (Schimanski, et al., 2019). LC and BIM can both be regarded as concepts and tools designed to reduce waste, improving building efficiency and increasing their value (Bi and Jia, 2016).

Considering the environment in which construction takes place, with multiple subcontractors involved, BIM-based user interfaces are ideal tools for providing process transparency (Sacks, Treckmann and Rozenfeld, 2009). Furthermore, visualisation is a fundamental element in Lean and BIM (Bi and Jia, 2016) and, in turn, visual management with Kanban systems improves communication between stakeholders (Guerriero, et al., 2017).

An immediate application of a Kanban system can be found in the development of a BIM model for a project. The BIM workflow is based on each modeller’s input in their respective discipline (architecture, structure, MEP engineering) (Lucena, Villena and Reyes, 2020). This system is similar to software development, where the work of each developer can be summarised on a visual card, the workflow being regulated by means of a Kanban board (Anderson, 2010). Lucena, Villena and Reyes (2020) found Kanban to be useful for controlling and managing MEP information for its incorporation into BIM.

The implementation of Kanban in BIM systems has given rise to various procedures and software. Zeng, et al. (2019) proposed a method for designing and implementing Kanban batches in the supply chain using BIM systems or tools. Sacks, Radosavljevic and Barak (2010) specified the requirements for implementing an LPS-based BIM-enabled extraction flow construction management software system named “KanBIM”. They also proposed a number of requirements for BIM-based Lean-related production management systems such as the following: visualisation of processes, products and methods; calculation and visualisation of work packages and task maturity; support for planning, negotiation, commitment and status feedback; establishment of pull systems; workflow stabilisation; and possibility of continuous improvement. According to Guerriero, et al. (2017), KanBIM is an example of a 3D BIM model linked to Kanban.

These authors also proposed the LPS stages for 4D BIM programming and developed the Smart Construction Planner tool that supports collaborative planning according to LPS (Guerriero, et al., 2017). Sticky notes are digitised so that the last planners can use them on multi-touch devices for process planning. In addition, a mobile app is available for managing constraints as well as production planning and control tasks (Schimanski, et al., 2021).

The Visilean® software package is a computerised translation of the KanBIM™ tool and is adapted to production, site and project management to control scheduling using Lean Construction and interaction with BIM. The model incorporates the task schedule from the first actions at the construction site to the commissioning and handover of the building, as well as the 3D model for visualisation (Kanai, et al., 2021).

Schimanski, et al. (2021) proposed a BIM-based production management system, characterised by a theoretical integration model for BIM and existing construction management techniques, as well as a method for applying these concepts in practice. This production management system, known as BeaM!, is a fusion of Lean and BIM (Schimanski, et al., 2021). It includes the so-called Digital Process Kanban (DPK), in which kanban cards are created by the last planners using the BeaM!-App installed on their smartphones and transmitted to the digital BeaM!-Board to be used to plan the cooperative phase (Schimanski, et al., 2021).

Conclusions

This review shows how the Kanban system has been successfully migrated from the automotive industry to the construction sector.

Kanban’s versatility allows it to be applied to the management and control of the entire construction process, both in the project development phase and in the material supply and execution phases.

Kanban is perfectly integrated into LPS, resulting in a useful tool for scheduling and coordinating the agents and companies involved in the implementation of the work units involved in the construction project. It can also be used as an independent LPS tool to manage the construction process.

The development of E-Kanban opens up a new field of application in construction. Combined with the Internet of Things it will facilitate an evolution towards concepts and techniques related to Industry 4.0.

The progressive implementation of BIM in the construction sector may encourage the perception of Kanban systems as useful tools. Proof of this is their effectiveness in terms of coordinating the team members involved in the development of BIM models.

Although software applications have been developed to implement Kanban systems using BIM, more research is needed to develop a recognised procedure that covers all expected Kanban needs.

Based on the results of this study, the following research questions are proposed: to what extent is Kanban being used in Spanish and European construction companies? What characteristics do these have, how are they using it, and what obstacles and facilitators have they encountered?

References

Ahmad, M., Dennehy, D., Conboy, K. and Oivo, M., 2018. Kanban in software engineering: A systematic mapping study. Journal of Systems and Software, [e-journal] 137, pp.96-113. https://doi.org/10.1016/j.jss.2017.11.045

Anderson, D.J., 2010. Kanban: Successful evolutionary change for your technology business. Sequim, WA: Blue Hole Press.

Arbulu, R., Ballard, G. and Harper, N., 2003. Kanban in Construction. In: 11th Annual Conference, International Group for Lean Construction. Virginia, USA.

Babalola, O., Ibem, E.O.E. and Ezema, I., 2019. Implementation of lean practices in the construction industry: A systematic review. Building and Environment, [e-journal] 148, pp.34-43. https://doi.org/10.1016/j.buildenv.2018.10.051

Barkmeyer, E. and Kulvatunyou, B., 2007. An ontology for the e-Kanban business process. Gaithersburg, MD: US Department of Commerce, National Institute of Standards and Technology. https://doi.org/10.6028/NIST.IR.7404

Bi, X. and Jia, X., 2016. Research on the integration of lean construction and BIM and a case study in Shanghai tower project. In: Qui, E., ed. Proceedings of the 6th International Asia Conference on Industrial Engineering and Management Innovation. Paris, pp.1027–36. https://doi.org/10.2991/978-94-6239-145-1_101

Boateng, A., 2019. Supply chain management and lean concept in construction: a case of Ghanaian building construction industry. Organization, Technology and Management in Construction: an International Journal, [e-journal] 11(1), pp.2034-43. https://doi.org/10.2478/otmcj-2019-0010

Boca, G. and Isitan, A., 2021. Transfer from traditional Kanban to Kanban 4.0 in smart factory. Review of Management & Economic Engineering, 20(3), pp.210-27.

Caldera, S., Ryley, T. and Zatyko, N., 2020. Enablers and barriers for creating a marketplace for construction and demolition waste: a systematic literature review. Sustainability, [e-journal] 12(23), p.9931. https://doi.org/10.3390/su12239931

Campoy-Muñoz, P. and Delgado, M., 2020. Estructura sectorial y productividad de la economía española. Panorama económico, [e-journal] 15(30), pp.79-103. https://doi.org/10.29201/pe-ipn.v15i30.253

Demir, S., Bryde, D., Fearon, D. and Ochieng, E., 2012. Re-conceptualizing Lean in construction environments ‘the case for “AgiLean” Project Management.’ In: 48th ASC Annual International Conference Proceedings. Associated Schools of Construction, pp.1-9.

Ekanayake, E. and Sandanayake, Y., 2017. LiVE approach: Lean integrated Value Engineering for construction industry. Built Environment Project and Asset Management, [e-journal] 7(5), pp.518-33. https://doi.org/10.1108/BEPAM-11-2016-0071

El Abbadi, L., El Manti, S., Houti, M. and Elrhanim, S., 2018. Kanban System for Industry 4.0 Environment. International Journal of Engineering & Technology, 7(4.16), pp.60-65.

Erazo-Rondinel, A., Vila-Comun, A. and Diaz, A., 2020. Application of the Last Planner® System in a Sports Infrastructure Project in Peru. In: Tommelein, I. and Daniel, E., eds. 28th Annual Conference of the International Group for Lean Construction (IGLC28). Berkeley, California, USA, pp.529-40. https://doi.org/10.24928/2020/0091

Francis, A. and Thomas, A., 2020. Exploring the relationship between lean construction and environmental sustainability: A review of existing literature to decipher broader dimensions. Journal of Cleaner Production, [e-journal] 252(2020), p.119913. https://doi.org/10.1016/j.jclepro.2019.119913

Garcés, G., 2020. Atributos de liderazgo entre los gerentes de proyectos: Una revisión desde el desempeño y la incertidumbre en los proyectos de remodelación de edificios. Revista Ingeniería de Obras Civiles, 10(1), pp.15-31.

Gayakwad, P. and Attarde, P., 2022. Lean Construction. International Journal of Research in Engineering, Science and Management, [e-journal] 5(5), pp.270-74.

Goh, M. and Goh, Y., 2019. Lean production theory-based simulation of modular construction processes. Automation in Construction, [e-journal] 101, pp.227-44. https://doi.org/10.1016/j.autcon.2018.12.017

Gómez-Luna, E., Fernando-Navas, D., Aponte-Mayor, G. and Betancourt-Buitrago, L., 2014. Metodología para la revisión bibliográfica y la gestión de información de temas científicos, a través de su estructuración y sistematización. Dyna, 81(184), pp.158-63. https://doi.org/10.15446/dyna.v81n184.37066

Greenhalgh, T., Potts, H., Wong, G., Bark, P. and Swinglehurst, D., 2009. Tensions and paradoxes in electronic patient record research: a systematic literature review using the meta‐narrative method. The Milbank Quarterly, 87(4), pp.729-88. https://doi.org/10.1111/j.1468-0009.2009.00578.x

Guerriero, A., Kubicki, S., Berroir, F. and Lemaire, C., 2017. IM-enhanced collaborative smart technologies for LEAN construction processes. In: 2017 International Conference on Engineering, Technology and Innovation (ICE/ITMC). IEEE, pp.1023-30. https://doi.org/10.1109/ICE.2017.8279994

Guo, J., Teng, J., Li, S., Wan, D. and Jiang, X., 2013. Study on electronic kanban management system in steel structure engineering of an international expo centre. Advanced Materials Research, [e-journal] 621, pp.375-80. https://doi.org/10.4028/www.scientific.net/AMR.621.375

Hepplestone, S., Holden, G., Irwin, B., Parkin, H. and Thorpe, L., 2011. Using technology to encourage student engagement with feedback: a literature review. Research in Learning Technology, [e-journal] 19(2), pp.117-27. https://doi.org/10.3402/rlt.v19i2.10347

Heravi, G. and Rashid, M., 2018. Developing an approach to develop and validate a lean construction plan using performance evaluation of repetitive subprojects. Journal of Architectural Engineering, [e-journal] 24(1), p.04017033. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000291

Jang, J. and Kim, Y., 2007. Using the kanban for construction production and safety control. In: Proceedings of the 15th Annual Conference of the International Group for Lean Construction (IGLC). Michigan, USA, pp.519-28.

Kanai, J., Gomes, C., Bertoli, S. and Fontanini, P., 2021. Visilean® application for monitoring and control of pre-fabricated concrete panels. Gestão & Produção, [e-journal] 28(3). https://doi.org/10.1590/1806-9649-2021v28e5800

Khalfan, M., McDermott, P., Oyegoke, A., Dickinson, M., Li, X. and Neilson, D., 2008. Application of kanban in the UK construction industry by public sector clients. In: 16th Annual Conference of the International Group for Lean Construction. University of Salford, UK. pp.347-59.

Ko, C. and Kuo, J., 2018. Lean formwork. In: González, V., ed. 6th Annual Conference of the International. Group for Lean Construction (IGLC). Chennai, India, pp.1283–90. https://doi.org/10.24928/2018/0211

Ko, C., Wang, W. and Kuo, J., 2011. Improving formwork engineering using the Toyota way. Journal of Engineering, Project, and Production Management, 1(1), pp.13-27. https://doi.org/10.32738/JEPPM.201107.0003

Lage Junior, M. and Godinho Filho, M., 2010. Variations of the kanban system: Literature review and classification. International Journal of Production Economics, [e-journal] 125(1), pp.13-21. https://doi.org/10.1016/j.ijpe.2010.01.009

Lappi, T., Karvonen, T., Lwakatare, L., Aaltonen, K. and Kuvaja, P., 2018. Toward an improved understanding of agile project governance: A systematic literature review. Project Management Journal, [e-journal] 49(6), pp.39-63. https://doi.org/10.1177/8756972818803482

Lu, W., Olofsson, T. and Stehn, L., 2011. A lean‐agile model of homebuilders’ production systems. Construction Management and Economics, [e-journal] 29(1), pp.25-35. https://doi.org/10.1080/01446193.2010.531027

Lucena González, C., Villena Manzanares, F. and Reyes Rodríguez, A., 2020. Método para la gestión de la información en proyectos desarrollados en entornos BIM. 24th International Congress on Project Engineering. Alcoy, España: Asociación Española de Ingeniería de Proyectos (AEIPRO), pp.451-66.

Mahfuth, K., Loulizi, A., Tayeh, B., Al Hallaq, K. and Aisheh, Y., 2020. Using safety system during the design phase to minimize waste in construction projects. Journal of King Saud University-Engineering Sciences, [e-journal] 34(3), pp.170-79. https://doi.org/10.1016/j.jksues.2020.09.006

Modrich, R. and Cousins, B., 2017. Digital Kanban boards used in design and 3D coordination. In: 25th Annual Conference of the International Group for Lean Construction (IGLC). Heraklion, Greece, pp.9-12. https://doi.org/10.24928/2017/0345

Moreira Barreto, A. and Heineck, L., 2012. Learning, structural masonry technology and Lean Construction a case study in a small building site. In: 20th Annual Conference of the International Group for Lean Construction. San Diego, USA.

Nightingale, A., 2009. A guide to systematic literature reviews. Surgery, 27(9), pp.381-84. https://doi.org/10.1016/j.mpsur.2009.07.005

Paez, O., Salem, S., Solomon, J. and Genaidy, A., 2005 . Moving from lean manufacturing to lean construction: Toward a common sociotechnological framework. Human Factors and Ergonomics in Manufacturing & Service Industries, 15(2), pp.233-45. https://doi.org/10.1002/hfm.20023

Pellicer, E., Cerveró, F., Lozano, A. and Ponz-Tienda, J., 2015. The last planner system of construction planning and control as a teaching and learning tool. In: Proceedings of 9th International Technology, Education and Development Conference (INTED2015). Madrid, Spain, pp.4877-84.

Perroni de Burgos, A. and Bastos Costa, D., 2012. Assessment of Kanban use on construction sites. In: 20th Annual Conference of the International Group for Lean Construction. San Diego, USA.

Pheng, L., Shang, G. and Peter, L., 2016. Using lean principles to reduce wastes in the concreting supply chain. International Journal of Construction Project Management, 8(1), pp.3-23.

Pons Achell, J. and Rubio Pérez, I., 2019. Lean Construction y la planificación colaborativa. Metodología del Last Planner® System. Madrid: Consejo General de la Arquitectura técnica de España (CGATE).

Qiaolan, J. and Bin, Z., 2021. Civil engineering construction management based on BIM technology. Forest Chemicals Review, [e-journal] 31, pp.31-37. https://doi.org/10.17762/jfcr.vi.47

Rivas Tovar, L., 2011. Las nueve competencias del investigador. Investigación Administrativa, [e-journal] 40(108), pp.34-54. https://doi.org/10.35426/IAv40n108.03

Rother, E., 2007. Revisión sistemática X Revisión narrativa. Acta Paulista de Enfermagem, [e-journal] 20, pp.v-vi. https://doi.org/10.1590/S0103-21002007000200001

Rybkowski, Z., 2010. Last Planner & its role as conceptual kanban. In: 18th Annual Conference of the International Group for Lean Construction. Haifa, Israel, pp.63-72.

Sacks, R., Treckmann, M. and Rozenfeld, O., 2009. Visualization of work flow to support lean construction. Journal of Construction Engineering and Management, [e-journal] 135(12), pp.1307-15. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000102

Sacks, R., Radosavljevic, M. and Barak, R., 2010. Requirements for building information modeling based lean production management systems for construction. Automation in Construction, [e-journal] 19(5), pp.641-55. https://doi.org/10.1016/j.autcon.2010.02.010

Safa, M., Weeks, K., ELHoubi, A., Sharma, N. and MacGillivray, S., 2022. Construction strategic project readiness assessment. Journal of Engineering, Project, and Production Management, 12(1), pp.13.

Salem, O., Solomon, J., Genaidy, A. and Minkarah, I., 2006. Lean construction: From theory to implementation. Journal of Management in Engineering, [e-journal] 22(4), pp.168-75. https://doi.org/10.1061/(ASCE)0742-597X(2006)22:4(168)

Sánchez Ruiz, L., Blanco Rojo, B. and Pérez-Labajos, C., 2013. Lean Management. Un estudio bibliométrico. Tiempo de Gestión, (15), pp.9-28.

Schimanski, C.P., Pasetti Monizza, G., Marcher, C. and Matt, D.T., 2021. Development of a BIM-based production planning and control system for Lean Construction through advancement an integration of existing management techniques. Frontiers of Engineering Management, [e-journal] 8(3), pp.429-41. https://doi.org/10.1007/s42524-020-0105-5

Schimanski, C., Monizza, G., Marcher, C. and Matt, D., 2019. Conceptual Foundations for a New Lean BIM-Based Production System in Construction. In: Pasquire, C.H., ed. 7th Annual Conference of the International. Group for Lean Construction (IGLC). Dublin, Ireland, pp.877-88. https://doi.org/10.24928/2019/0106

Si, T., Li, H., Lei, Z., Liu, H. and Han, S., 2021. A dynamic just-in-time component delivery framework for off-site construction. Advances in Civil Engineering, [e-journal] 2021, p.9953732. https://doi.org/10.1155/2021/9953732

Sivaganesh, P. and Ratnayake, R., 2018. Application of Last Planner® system in product concept development phase: Use of lean concepts in academic project work. In: 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM). IEEE, pp.351-55. https://doi.org/10.1109/IEEM.2018.8607584

Snyder, H., 2019. Literature review as a research methodology: An overview and guidelines. Journal of Business Research, [e-journal] 104, pp.333-39. https://doi.org/10.1016/j.jbusres.2019.07.039

Son, H., Kim, C., Kim, H., Han, S. and Kim, M., 2010. Trend analysis of research and development on automation and robotics technology in the construction industry. KSCE Journal of Civil Engineering, [e-journal] 14(2), pp.131-39. https://doi.org/10.1007/s12205-010-0131-7

Straçusser, G., 2015. Agile project management concepts applied to construction and other non-IT fields. Orlando: PMI® Global Congress.

Tapase, A., 2019. Book Review: Toyota Kata- Managing people for improvement and superior results. Lean Construction Journal, (2019), pp.21-25.

Tapler, C., 2014. Analysis of the application of different production and material flow mechanisms on construction sites. In: 2014 International Conference on Computational Science and Computational Intelligence. IEEE, pp.241-46. https://doi.org/10.1109/CSCI.2014.48

Tezel, A., Koskela, L., Tzortzopoulos, P., Formoso, C. and Alves, T., 2015. Visual management in Brazilian construction companies: Taxonomy and guidelines for implementation. Journal of Management in Engineering, [e-journal] 31(6), p.05015001. https://doi.org/10.1061/(ASCE)ME.1943-5479.0000354

Tezel, A. and Aziz, Z., 2017. From conventional to IT based visual management: a conceptual discussion for lean construction. Journal of Information Technology in Construction, 22, pp.220-46.

Tezel, A., Taggart, M., Koskela, L., Tzortzopoulos, P., Hanahoe, J. and Kelly, M., 2020. Lean construction and BIM in small and medium-sized enterprises (SMEs) in construction: a systematic literature review. Canadian Journal of Civil Engineering, [e-journal] 47(2), pp.186-201. https://doi.org/10.1139/cjce-2018-0408

Torres-Carrión, P., González-González, C., Aciar, S. and Rodríguez-Morales, G., 2018. Methodology for systematic literature review applied to engineering and education. In: 2018 IEEE Global engineering education conference (EDUCON). IEEE, pp.1364-73. https://doi.org/10.1109/EDUCON.2018.8363388

Tranfield, D., Denyer, D. and Smart, P., 2003. Towards a methodology for developing evidence‐informed management knowledge by means of systematic review. British Journal of Management, 14(3), pp.207-222. https://doi.org/10.1111/1467-8551.00375

Valente, C., Brandalise, F. and Formoso, C., 2019. Model for devising visual management systems on construction sites. Journal of Construction Engineering and Management, [e-journal] 145(2), p.04018138. https://doi.org/10.1061/(ASCE)CO.1943-7862.0001596

Van Wee, B. and Banister, D., 2016. How to write a literature review paper? Transport Reviews, [e-journal] 36(2), pp.278-88. https://doi.org/10.1080/01441647.2015.1065456

Vieira de Carvalho, A., Denis Granja, A. and Gomes da Silva, V., 2017. A systematic literature review on integrative lean and sustainability synergies over a building’s lifecycle. Sustainability, [e-journal] 9(7), p.1156. https://doi.org/10.3390/su9071156

Wnuk, K. and Garrepalli, T., 2018. Knowledge management in software testing: a systematic snowball literature review. e-Informatica Software Engineering Journal, 12(1), pp.51-78.

Wohlin, C., 2014. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In: Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering (EASE ’14). London, UK, pp.1-10. https://doi.org/10.1145/2601248.2601268

Xing, W., Hao, J., Qian, L., Tam, V. and Sikora, K., 2021. Implementing lean construction techniques and management methods in Chinese projects: A case study in Suzhou, China. Journal of Cleaner Production, [e-journal] 286, p.124944. https://doi.org/10.1016/j.jclepro.2020.124944

Zeng, N., Ye, X., Peng, X. and König, M., 2019. Applying kanban system in construction logistics for real-time material demand report and pulled replenishment. In: Proceedings of the 36th International Symposium on Automation and Robotics in Construction (ISARC 2019). IAARC Publications, pp.1018-25. https://doi.org/10.22260/ISARC2019/0136