Construction Economics and Building

Vol. 22, No. 3

September 2022

RESEARCH ARTICLE

Production Capability Creation (PCC) for Collaborative Construction Projects – A Qualitative Study From Finland

Petteri Annunen1, Harri Haapasalo2,*

1 Department of Industrial Engineering and Management, University of Oulu, Oulu, Finland, petteri.annunen@oulu.fi

2 Department of Industrial Engineering and Management, University of Oulu, Oulu, Finland,

harri.haapasalo@oulu.fi

Corresponding author: Harri Haapasalo, Department of Industrial Engineering and Management, University of Oulu, Oulu, Finland, harri.haapasalo@oulu.fi

DOI: https://doi.org/10.5130/AJCEB.v22i3.8146

Article History: Received: 05/04/2022; Revised: 12/08/2022; Accepted: 16/08/2022; Published: 20/09/2022

Abstract

The construction industry has been suffering from modest productivity development in recent decades. To address the recognized problems, collaborative delivery methods are replacing traditional project delivery models, especially in large and complex projects. The aim of this research is to describe the production capability creation (PCC) process as a solution for planning the production phase. The PCC process should be implemented parallel to the design phase and owned by the production. A qualitative and inductive approach, based primarily on case company interviews, is applied to identify the twelve most important challenges for preplanning in the design phase from a group of different types of stakeholders in construction projects. Based on these challenges, the main areas of PCC are structured, solving the depicted production challenges, enabling a wasteless and cost-efficient production phase to avoid unnecessary delays and problems. Parallel implementation of PCC and design processes of the building naturally also improve the result of the design itself. With PCC, contractors can recognize the need for improvement in their processes but, more importantly, can directly contribute to the design of the building. Described PCC process solves major challenges emerging from the case company interviews. Earlier literature on capability creation is scarce, and for the construction industry it is even more narrow. The PCC process presented in this research enables significant improvement in efficiency and effectiveness, and the elimination of waste in the construction industry.

Keywords

Collaborative Projects; Supply Chain Management; Design for Excellence; Production Capability Creation

Introduction

Productivity development in the construction industry has been modest in the recent decades (Pekuri, Haapasalo and Herrala, 2011; Dixit, et al., 2019; Teräväinen and Junnonen, 2019). Fragmentation and low level of collaboration among project stakeholders have been identified as among the main reasons for this (Aapaoja, et al., 2013; Larsen, et al. 2018; Halttula, Haapasalo and Silvola, 2020). Traditional contract models such as design–bid–build and design–build have resulted in problems with key processes, information sharing, and trust (Halttula, Aapaoja and Haapasalo, 2015; Sarhan, et al., 2018). Division in terms of design and production phases does not enable collaboration, which is seen as a prerequisite for successful projects (Love, Irani and Edwards, 2004; AlMunifi and Almutairi, 2021).

Recently, collaborative delivery models such as integrated project delivery and project alliancing have enabled development—improving collaboration among participating companies and across project phases (Hietajärvi, Aaltonen and Haapasalo, 2017a; 2017b). In collaborative contracts, once the main suppliers (members of the collaborative contract) are selected and permitted to collaborate at a very early phase, they are able to create a more efficient design for the end result (Aapaoja and Haapasalo, 2014), incorporate their competence in creating the most efficient delivery plan (Aapaoja, et al., 2013), and even provide innovative solutions for the client (Hietajärvi, Aaltonen and Haapasalo, 2017b). In this way, projects avoid a range of problems between the design phase and the activities being performed (De Blois, Lizarralde and De Coninck, 2016).

The emerging development is at least partially due to new contract models. Among others, Gerth, et al. (2013) and Halttula, Haapasalo and Silvola (2020), introduced new concepts from other industries to construction industry. Methods such as design for excellence (DfX) and capability creation (CC) aim to enable more accurate value creation not only for the client but also for other stakeholders. Such methods also aim to increase the efficiency of a project through the elimination of waste (Halttula, et al., 2017) and overall constructability (Khan, 2015). DfX is a method that takes the requirements of the key project stakeholder (stakeholder X) into account even at the design phase of a project (Lehto, et al., 2011). In turn, the XCC method aims to plan and create key capabilities for stakeholder X and the project during the early phase to ensure efficient project implementation (Tolonen, et al., 2017; Annunen, et al., 2021). The complementary nature of DfX and XCC processes has been presented by Tolonen, et al. (2017); namely, how design for supply chain (DfSC) incorporates the requirements of the supply chain into design while the supply chain capability creation (SCCC) process creates the capabilities for these supply chain requirements.

The main drivers of this study (DfX and CC utilisation) are improvements for the final value delivery and efficiency of a project (Lehto, et al., 2011; Halttula, et al., 2017; Verrollot, et al., 2017). Therefore, aim is to create content for the production capability creation (PCC) process that is applicable to the construction industry. The PCC is a separate systematic process that takes place parallel to a building’s design or development phase and should be managed by the stakeholder responsible for the construction (cf. Annunen, et al., 2021). The traditional approaches of design and construction collaboration (cf. Kleinsmann, et al., 2012) and design management (cf. Herrera, et al., 2020) are not neglected, but target is to create content for the PCC process that aims to improve constructability and provide a dedicated responsible role. Earlier research emphasized the benefits of involving construction stakeholders during the design process but has not explained directly how readiness for delivering a product (building) can be created in parallel with the design process (Tolonen, et al., 2017; Verrollot, et al., 2017), nor there are any systematic models or process for preplanning. This research position requires a foundation that enables collaboration, or at least a contract model that does not restrict it. All this leads us to the following research questions:

RQ1: Which key issues require preplanning in the collaborative project design phase to ensure an efficient production phase?

RQ2: What are the main areas and process for production capability creation in collaborative projects?

In the literature review, the fundamental setup for collaborative projects is summarized, streamlining supply chain management, and DfX as a pre-requirement for CC to synthesize justification for early planning. After describing the research process, the main challenges of production and the findings on the preplanning elements of the design phase of collaborative construction projects are presented (RQ1). Based on these, the framework and the main areas of the PCC process are presented (RQ2). The final sections of the study cover the discussion and present the conclusions. The main impact of PCC process enables companies to improve their efficiency by saving time, gaining benefits through repeatability and by reducing the variation in their operations.

Literature review

Collaborative project models and integration

Traditionally, the construction business has mainly been using design–bid–build or design–build project models (Walker, 2018). In design–bid–build projects, the client chooses the main designer, who manages the design work. After a competitive tendering process, the client selects a contractor to manage the overall project. The lowest-cost bid usually wins, which typically leads to problems later on, especially in complex or largescale projects involving difficult and precise design work (Halttula, Aapaoja and Haapasalo, 2015). Changes during the production phase mean that the main contractor and subcontractors can then charge for the extra work (Halttula, Aapaoja and Haapasalo, 2015), and, as a result, project costs and schedules are likely to be adversely affected (Yeganeh, Azizi and Falsafi, 2019). In the case of design–build projects, the main contractor is responsible for managing both design and construction.

Collaborative projects have been seen as the answer to these problems, especially for large and complex construction projects (Lahdenperä, 2012; Børve, et al., 2017; Mesa, Molenaar and Alarcón, 2019). In collaborative projects, project participants aim for the same and jointly agreed targets, for which suboptimization is precluded. According to Børve, et al. (2017), the project owner in a collaborative model integrates contractors and other major contributors into the project; trust and commitment are central to it, with continuous feedback given and improvement attained. A collaborative method combines the potential knowledge, experience, and decision-making capabilities of the companies involved (Walker, 2018), aligning stakeholders’ objectives through risk-sharing and joint organization and decision-making (Lahdenperä, 2012). According to Ross (2003), service providers share the “pain” or “gain”, to achieve their target through collective responsibility and ownership.

A further key element in collaborative projects is early involvement and integration, which enables the availability of critical information from both internal and external stakeholders already in the design phase, all of which is to be used for better planning and preparation for the production phase (Aapaoja and Haapasalo, 2014). Early involvement means a systematic approach is taken to identify, analyze, and classify key stakeholders and involve them in the front-end of a project, enabling them to contribute to value creation (Aapaoja and Haapasalo, 2014; Halttula, et al., 2017). Integration refers to collaborative methods and behavior to promote an environment whereby information is exchanged transparently among stakeholders to ensure the best decisions are made (Baiden, Price and Dainty, 2006). However, early involvement and integration are quite generic concepts, and a substantial amount of research is needed to take these to a level whereby they can operate in practice.

Challenges in the construction supply chain

Supply-chain management (SCM) refers to the design, planning, execution, control, and monitoring of activities in the supply chain. It focuses on intensifying the flow and value creation in the chain and tries to minimize total costs with respect to existing conflicts among stakeholders (Fawcett and Magnan, 2002). SCM can also be seen as a “network of organisations that are involved, through upstream and downstream linkages, in the different processes and activities that produce value in the form of products and services in the hands of the ultimate customer” (Christopher, 2011). In construction, supply chains include multiple subcontractors and businesses that directly or indirectly provide the requisite materials or services for a project (McDermotti and Khalfan, 2012; Meng, 2013). Supplier relationships in the construction supply chain are short-term and often adversarial (Bresnen and Marshall, 2000; Saad, Jones and James, 2002; Meng, 2013; Fulford and Standing, 2014), and they are adjusted based on a risk-shedding attitude, causing the industry to suffer from a lack of interoperability, collaboration, and information exchange (Succar, 2009; Papadonikolaki, Vrijhoef and Wamelink, 2016). The traditional arm’s length and adversarial model toward the supplier is centered on maximizing the bargaining power of buyers on the one hand and minimizing their dependency on suppliers on the other, to keep the suppliers at arm’s length without any form of commitment (Dyer, Cho and Cgu, 1998). In contrast, the more collaborative model proposed by Dyer, Cho and Cgu (1998) achieves better performance and quality improvement through better information sharing and the coordination of tasks with minimum transaction costs.

From the SCM literature, it is evident that a supply chain’s performance improvement requires, among other things, tighter stakeholder relationships and transparent processes. Womack and Jones (2003) discussed value stream management and lean implementation. Another discussion has emerged about the elimination of waste (in the upstream) to focus on solving problems before they emerge (in the downstream). Originally, Ohno’s (1988) seven initial types of waste have been analyzed in more detail through later research (cf. Womack and Jones, 2003) and tailored specifically to construction (Koskela, 2004). Halttula, et al. (2017) reviewed the literature and performed empirical analysis to prioritize wastes in the construction industry (the twelve most important forms), namely communication and documentation, people’s unused potential, defects, making wrong products or services, unnecessary movements, inadequate processing, making do, overloading, poor constructability, overproduction, waiting, and unnecessary transportation. Almost all of these can be linked to inaccurate or incorrect planning in an operation, thereby highlighting the importance of preplanning.

Design for excellence and capability creation

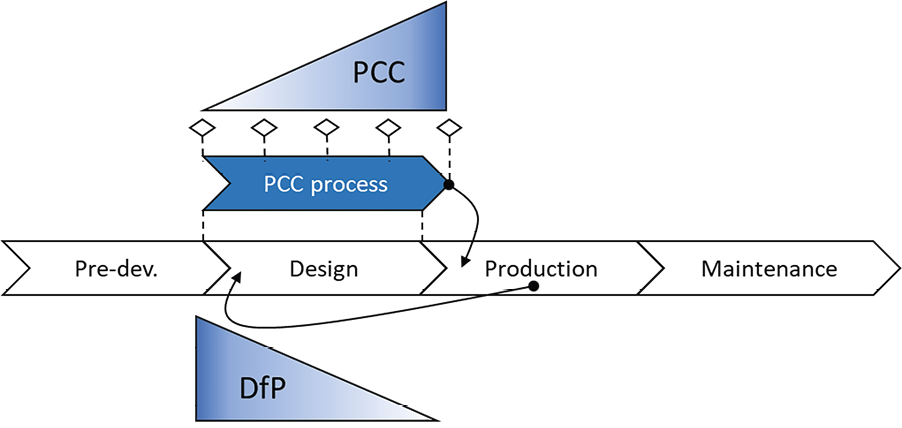

Complementary DfX and CC approaches have been applied to product development projects involving several key Xs—for example, DfT (testing), DfA (assembly), DfL (logistics), and DfE (environment), DfS (safety) etc. (Lehto, et al., 2011; Teo, et al., 2016). In construction, key Xs in current use include design for manufacturing (DFM), design for assembly (DFA), and design for manufacturing and assembly (DFMA) (Gerth, et al., 2013; Lu, et al., 2021). Design for construction (DfC) has been discussed in terms of constructability (Khan, 2015) in order to avoid problems and excessive costs during the construction phase. The problem identified in this discussion is that there is no dedicated party to present the requirements, constraints, and best practices and no specific means for doing this. Once design for production (DfP) is in use, there should be a dedicated stakeholder whose role is to set these for the design process. At the same time, CC processes run parallel to the product design process, influencing its governance as well as target setting, key metrics, tasks, milestone criteria, and roles.

The main goals of CC are to improve product design and facilitate efficient production. There should be a dedicated capability manager responsible for related work during the design process (Tolonen, et al., 2017). Tolonen, et al. (2017) further identified mature process platforms as a precondition for efficient CC activities. The design process must be described, and capabilities created parallel to it, in addition to DfX concepts. For the third requirement, a design process governance model is needed to support the work. Verrollot, et al. (2017) highlighted the importance of an efficient milestone process and use of milestone criteria in product development, defining the early involvement and integration of all the relevant stakeholders that are important for success. For high-quality capability creation work, the main KPIs are the quality of the product itself and the related processes (Verrollot, et al., 2017).

Synthesis

Earlier literature has provided an understanding of what early stakeholder involvement and integration mean during the front-end phase of the project, and especially of how important they are for enabling project success. In traditional contracts, the opportunity for early involvement is possible only in extreme cases, and there is little motivation for it; however, collaborative contracts provide an ideal platform for this. Details of early stakeholder involvement and integration, how those are executed, and the essential actor’s roles, responsibilities, and activities, were much more limited in earlier research.

The literature (cf. Gerth, et al., 2013; Lu, et al., 2021) has depicted the importance of production or the manufacturing process in general as a stakeholder in construction projects. Therefore, it can be considered self-evidently as a key stakeholder, with DfP setting requirements for design, naturally with other key stakeholders. In this study, the production is used as the process, for which CC is aimed to define.

The CC process seeks to improve (product) design and facilitate efficient production through preplanning (Tolonen, et al., 2017). Efficient production can be divided into several subareas, but the overall aim of it is accuracy, in terms of time, lower production costs, and achieving the required quality. DfP and PCC are counterpart processes that support each other (see Figure 1). They both require and utilize recognition and analysis of the most important stakeholder or area concerning the product and its production. The main idea of DfP is to recognize the main stakeholder (production) and elicit, collect, document, and analyze the requirements of that stakeholder, to the product design in the early phase. Then the same stakeholder (production), parallel to the design phase, creates the required capability. Once production begins, production operations are then simply implemented. DfX’s effort is the greatest during the start of the design phase, but then this effort diminishes as the project proceeds. The relative importance of PCC increases when the project has started.

Figure 1. Complementary nature of DfP and PCC (modified from Tolonen, et al., 2017, and Annunen, et al., 2021), connected with general collaborative construction project phases.

Based on earlier research, PCC processes can bridge major gaps in the design for the production phase, especially in collaborative projects. The cornerstones of PCC in construction projects, however, require mature core processes (design and production) and a clear governance model for implementation (Annunen, et al., 2021). In collaborative projects, aims, organizational structure, and joint responsibilities form a sound basis for implementing PCC processes. The process owner’s role and the milestones for controlling progress are also critical for multi-stakeholder processes (Kohlbacher and Gruenwald, 2011).

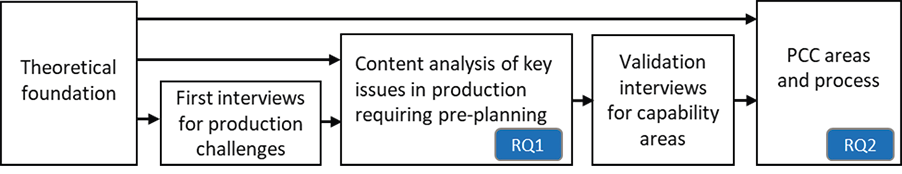

Research process

Given the scarcity of previous research on PCC (cf. constructability), this study adopted a qualitative and inductive approach (Bryman and Bell, 2011; Figure 2). First, a literature review was performed to understand the foundation. Based on the literature synthesis, the data collection topics were scoped, and a semi-structured interview guide was created (Appendix 1), for highlighting which issues require more detailed understanding of preplanning in the design phase, to ensure an efficient production phase. After the first interviews and analysis, more in-depth validation interviews were performed with selected industry experts to validate the findings from the first interviews, and to outline in particular the experts’ views on the definitions of the main areas of PCC in collaborative projects.

Collaborative project models, supply chain management in construction and capability creation formed the theoretical foundation for the study, guiding the data collection in the interviews. The first interviews were conducted in thirteen key stakeholder organizations involved in collaborative projects. In order to secure rich data, different types of stakeholders in construction projects, which were critical for production preplanning in the design phase, were chosen. Interviewed stakeholders included building authority and client, who had proved their expertise and knowledge of production. Selecting the informants was based on good access to the companies and the informant expertise in the field. Purposeful interview sampling was utilized based on Denzin and Lincoln (2005). Interviewees were asked, if all relevant roles are included in the interview set-up, to secure data validity and consistency. Willingness and availability to participate in the interview was secured beforehand. The ability to communicate experiences and opinions in an expressive and reflective sense was noted, as advised by Palinkas, et al. (2015). The organizations mainly operated in Finland and had experience with several collaborative projects. Informants were selected with experience of collaborating with each other on earlier projects. The unit of analysis in this study was a collaborative construction project with a design phase and a production phase. Any specific case project was not analyzed, but rather the cumulative experiences of the general production phase challenges of collaborative projects in Finland.

The data were collected from semi-structured interviews (Clifford, et al., 2016), before which respondents were provided interview guidelines to give them an idea of the scope and subject matter. The interviews were conducted in groups, with one interviewer responsible for asking questions and another for taking notes from the responses. All interviews were also recorded for more detailed analysis. The interview questions were created based on the most important topics raising from the literature review, to find out the most critical issues and to form the basis for the PCC process. Questions covered basic descriptive data about the organization, interviewee, and experiences related to the processes and key methods of collaborative models and supply chain management. Key questions included asking about the most critical issues regarding preplanning and preparation in the design phase and the issues that caused problems in the production phase.

* Based on the European Commission definition. Small = 10-50 employees, 2-10M€ turnover; Medium = 50-250 employees, 10-50M€ turnover; Large = more than 250 employees, more than 50M€ turnover.

The information from the first interviews was analyzed using content analysis principles, consisting of data collection, coding, content analysis, and results interpretation, following Duriau, Reger and Pfarrer (2007). The research team first summarized the overall findings and then began to identify emerging issues requiring preplanning and smaller indicators related to the new PCC method requiring preplanning (see Table 4 for a detailed description of the key issues). In the second phase of the analysis, during the second formal coding round, key issues emerged and were combined with the depicted challenges and connected to groups (capability creation areas) to build up the PCC process structure. A proposal of the PCC areas was created based on the literature, analysis of the first interviews, and finally from the validation interviews.

For the validation interviews, unstructured discussions were used with three professionals (Table 2), with particular experience in areas of PCC, to validate the findings. These validation informants were known to have extensive insight into the construction industry and were familiar with the benefits of CC processes. The validation interviews included detailed discussions related to all the key challenges and full PCC process, supporting the proposal of the PCC areas. Based on the informant feedback, the general high-level set-up for the PCC process was finalized.

| Company | Company role | Interviewee role | Company size* |

|---|---|---|---|

| N | Main contractor | Chief executive officer | Medium |

| O | Main contractor | Chief development officer | Large |

| P | Consultant | Partner | Small |

* Based on the European Commission definition

Results

Common findings from the first interview round

All the interviewed organizations reported similar principles and methodologies regarding their approach to collaborative projects. All the companies had followed the description of project alliances (RT103239, 2020) for Finnish construction regulations. They reported utilization of largely the same lean tools and key performance indicators, and the stakeholders in the majority of such alliances were quite similar. Eleven of the participating organizations were working on the same large and complex project in addition to their earlier experiences of collaborative projects.

All participating organizations used the same basic project alliance process that involved five phases: strategy, predevelopment, development (design phase), implementation (production phase), and maintenance. In collaborative projects, the key stakeholders were the clients, users, main designers, and main contractors, as well as the sub designers, subcontractors, and suppliers. A collaborative mindset was considered central to this way of working, and the phrase “best for the project” was mentioned in most of the interviews as the basis for all decisions.

In all collaborative projects, target value design (TVD) was among the key guiding principles. Regarding the key lean tools, all participants reported using big room and last planner; Kanban, VSM (value stream mapping), 3P (product preparation process), A3-decision matrix, and CBA (choosing by advantages) were also widely used. Some also mentioned other lean-related tools. Most of the participating organizations used similar types of KPIs related to money, time, quality, and safety. Most also used building information modelling (BIM), which was increasingly valued.

Key issues requiring preplanning in the design phase

Central to the first interviews was finding out, which issues required more preplanning and concentration in the design phase of collaborative projects to achieve a successful production phase, and cross-checking whether those were the same issues that caused most of the problems during the production phase. The aim of these questions was to find support for the development of key areas for a possible PCC process. CC-related terminology was deliberately not used to ensure that the interviewees had the freedom to point out all the related key issues and not to lead them to ready-made solutions.

In the analysis of the first interviews, one of the key findings was that issues, which should have been concentrated on more in the design phase were, from a data analysis point of view, basically the same as the issues causing problems in the production phase. The research group coded the key findings and combined them into twelve key areas for improvement (Table 3).

Most of the participating organizations viewed change management in the production phase as a key problem. This relates to several other critical areas, including decision management, how well the interface between the design and production phases is managed, how client requirements are managed, and how organizations cooperate within a project alliance. All of these can lead to excessive changes in the production phase, and these changes were not being managed as well as they needed to be. Even the change management process was not sufficiently well defined.

Many concerns were also raised about big room functionality. According to company C (direct citations are accurate representative replies, reflecting the company experiences):

Working efficiency is low in big room meetings, and it is difficult to find one’s own peace.

Several raised concerns about efficiency and whether the right people were in the right place at the right time. One proposal to make big room usage more efficient was to introduce a facilitator.

Decision management is critical in large and complex collaborative projects, but this is not always the case, according to a representative from organization D, who stated:

In big collaborative projects in particular, project management efforts do not meet the required level, which is why things proceed slowly and we run into problems.

If the organizational structure is too complicated, decisions may be delayed, and some of them may not be properly communicated to the organization as a whole. Forming decision boards is an important means of ensuring effective decision-making. According to a representative of organization G:

Without sufficient attention to forming a board, the project is very likely to be hindered by inefficient decision-making.

Decisions must also be taken at the appropriate organizational level. From a sub designer’s perspective (company C), designers should have more power and scope to make decisions; otherwise, decision management is slow and difficult because there are too many stakeholders with too many opinions about the design.

There are some fundamental problems in forming the collaborative organization. As company M described it:

Users, especially clients, are missing or play too small a role in the collaborative project management group.

This causes several problems, as the voice of the client remains too quiet, and the project cannot proceed in the most efficient way so that value is delivered to the client.

Roles and responsibilities should be clear. Company E also raised the problem of resourcing:

Among stakeholders, users are especially problematic because they are not allocated to the project, and while they have their own job to do, they cannot participate enough in the design phase.

Similarly, those involved in the production phase (i.e., construction companies) are not sufficiently involved with design phase resources (i.e., designers). Choosing the correct stakeholders, and even the correct people among the stakeholders, is seen as important.

Sourcing and subcontracting concerned five of the companies, but their concerns were notable and, moreover, were shared by all the key companies that used subcontractors. According to company D:

Subcontracting decisions should be made early enough in the development phase to utilize product information—for example, through early use of BIM.

A company L representative elaborated on this point:

The ability to implement a project successfully requires procurement planning even in the tendering phase. Subcontractor selection must be managed carefully for recruiting reliable subcontractors with a high-quality supply chain that can support project targets.

Clearly, sourcing/subcontractor management and integration is among the key challenges in Finnish collaborative projects, and there is a need to consider whether subcontractors are to be included in the same collaborative agreement or managed through a traditional tendering process. The increasing use of subcontracting in collaborative projects highlights the importance of this issue.

Target setting should be visible, and KPIs should guide work in the right direction. Collaborative projects should as far as possible use real-time KPIs rather than managers “looking in the rear-view mirror.” KPIs are especially important when moving from the development phase to the implementation phase.

One common view was that project alliance–related training and usage of lessons to learn were not being utilized as they should be. According to a representative from company C:

Training is available, but in reality, only a small proportion of project personnel have participated in it.

Regarding collaborative project roles and responsibilities, a lack of information about exact client requirements would cause problems across an alliance. As a representative from company G noted:

If the client is not willing to put in the effort right from the start of the project, this will very likely translate into wasted money in the latter stages … The project owner must set starting points that are sufficiently precise.

A representative from company H described this problem in another way:

The client’s desire to handle the project as a collaborative one is essential for success. Additional costs will be incurred if the constructor has to make additional efforts to ensure compliance with the alliance contract in circumstances whereby the client is unsure of the model and its assumptions.

Regarding decision management, according to company C:

When the client is not sufficiently involved, some decisions need to be delayed. And if there is no clear understanding about what designers and construction companies can decide on, decisions are not managed properly and are therefore delayed.

In the design phase, one of the most important requirements is to understand the client’s needs in as much detail as possible, as special requests during the production phase can cost too much to keep the project on target.

Cooperation is vital, and lack of communication will damage a project. These are common problems in all modern projects, but collaborative projects also face some specific issues, as described by an interviewee from company H:

Designers should participate more in common project work. [The fact that they don’t] is most likely a consequence of all the years they have spent working as consultants, simply doing the tasks they’ve been assigned.

For people who are used to the traditional design–bid–build project model, it takes time to learn how to cooperate for the common good.

At the end of the project design phase, moving to the production phase was seen as a critical step. According to a representative from company L,

A typical problem is that development of the project stops in the design phase even if there is still half of the planning yet to be done and efforts are not fully devoted to the project. The planning of solutions is considered too deeply, instead of concentrating on developing the way to operate, as takt time production has done. There is also a critical phase between design and construction when a lot of new people are starting to work on production. Training and coaching should be done with more precision, and construction companies should be more involved.

According to an interviewee from company M:

Parties need to be committed to agreed-upon issues when moving from the development phase to the implementation phase, as the organization size will increase by a factor of ten and many changes will be made in the organization.

The fact that the production phase stakeholders (construction companies) are involved too late in collaborative project work was seen as a common problem.

General quality management and innovation management through workshops were considered important, as a representative from company H put it:

Innovation workshops boost collaboration and enthusiasm for a project, which can help to build trust. The innovation itself does not necessarily have to cost a significant amount of money.

From the analysis, the typology of key issues requiring preplanning in the collaborative project design phase was quite consistent, and surprisingly so (Table 4). Some of the identified challenges were related to collaborative project methods (e.g., big room utilization) and basic processes (e.g., change management). However, some related to common supply chain capability issues such as subcontracting and quality management. In summary, as collaborative project methods are relatively new to all stakeholders, many of the key issues arise from new practices and the demanding nature of the project set-up. By implication, collaborative methods require leadership to ensure that they are optimally utilized.

Validating the areas of PCC

After the analysis of the first interviews, the key activities to be included in the PCC process were listed. Logical groups of activities proved difficult to establish, but preliminary groupings were formulated for validation by beginning with the easiest ones.

In the validation interviews, support was found for the premise that the PCC process should be extended to include more general topics, beyond those mentioned in the first interviews. As the expert from company O stated:

All the challenges identified in the first interviews are valid, especially in large collaborative projects, but the framework for PCC should also include some general supply chain management–related activities, which are important for the industry.

Based on the validation interviews, two activities were moved to more appropriate groups, and two new activities were also added. In the last phase of the validation process, the interviewees helped to specify names for activities and groups (PCC areas).

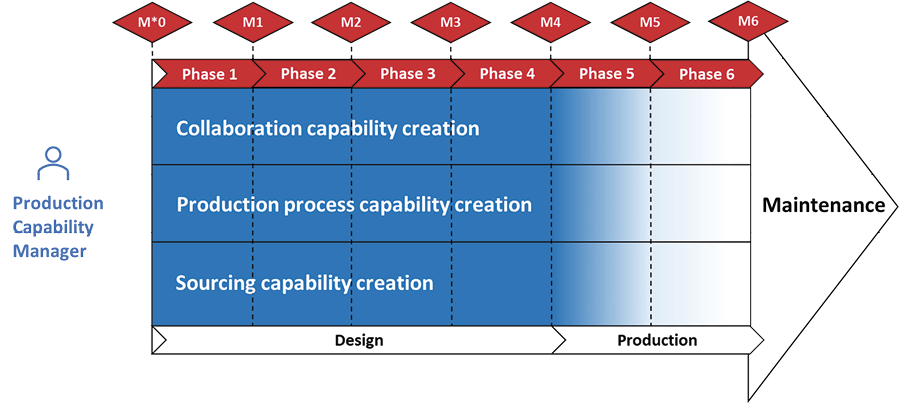

The finalized process structure (Table 5) included collaboration, production process, and sourcing as production capability creation process areas, covering most of the identified challenges such as change management, decision management, subcontracting, and quality management. Certain other general construction-related issues, which were not mentioned in the first interviews, were also included (e.g., safety, environmental issues, logistics).

There was also a recognized need for a production capability manager (PCM) role in collaborative construction projects. As an interviewee from company P said:

A PCM role would definitely be needed in collaborative projects. At present, construction companies do not engage in sufficient discussion with development personnel, and the needs of construction companies are not sufficiently visible during the design phase.

The optimum set-up would include a PCM to lead capability creation work during the design phase from a construction perspective. The PCM would be part of the respective management team leading the design phase. Separate production process capability and sourcing capability managers might be needed in large and complex projects; in smaller projects, the PCM could occupy all three roles.

| Area of production capability creation | Activities included in the area (Numerals refer to key issue requiring preplanning number in Table 4) |

|---|---|

| Collaboration capability creation | Forming and maintaining organization set-up [4, 8] Defined roles and responsibilities for activities Efficient and transparent decision management [3] Change management process and practices [1] Communication methods [9, 10] Defined follow-up training [7] |

| Production process capability creation | Production and material management (both onsite and prefabrication) Time management (scheduling and follow-up) Risk management [12] Cost management (TVD, close follow-up of KPIs) [6] Quality management (including big room and innovation practices) [2,12] Safety and environmental management |

| Sourcing capability creation | Supplier selection process [5] Affective supplier management [5] Subcontracting [5] Purchasing [5] Logistics and site logistics–related methods |

The collaboration capability creation area includes all the needed project-related general capabilities, starting from efficient organizational setup and defined roles and responsibilities. Some of the key challenges found in the first interviews, namely efficient decision management and change management, belong to this common area. The role of communication methods and practices cannot be overestimated. Several types of training (lean, technical, and project method–related) belong to this area.

Production process capability creation includes more technical and construction-related activities, such as construction and material management (for both onsite construction and the prefabrication of parts). Time management (e.g., takt time planning) also belongs in this area, along with risk management, quality management, and innovation management–related activities such as innovation workshops. Cost management, including TVD-related activities, is among the most important elements of every project, and the construction industry places increasing emphasis on safety and environmental management.

Sourcing capability creation includes all activities related to the growing area of subcontractors and suppliers, from supplier selection to the effectiveness of suppliers, subcontractors, and purchasing management. Logistics and site logistics–related activities are also important elements in this area.

The general process setup principle is presented in Figure 3, namely a PCC process with three main areas as part of the construction project. Process phases 1–6 and milestones 1–6 in the figure follow the current construction project phases used in Finnish collaborative construction projects and need be modified based on local processes. The most important thing is to agree the actual activities and tasks for each main PCC area and the project phase, to be followed up in each milestone, by the agreed persons responsible.

Figure 3. PCC processes as part of construction project. (M = milestone)

Discussion

The PCC in this study is in line with CC presented in other industries by Tolonen, et al. (2017), Verrollot, et al. (2017), and Annunen, et al. (2021). The importance of creating relevant capabilities during the project’s earlier phases, is highlighted in this study. The findings confirm the importance of cooperation among the various project participants and with the client (Kang, et al., 2020), as well as the need for early involvement in construction (Aapaoja and Haapasalo, 2014; AlMunifi and Almutairi, 2021) at a more detailed level. This study also complements research on design for construction by Gerth, et al. (2013) and other DfX studies on construction (Lehto, et al., 2011; Halttula, et al., 2017; Lu, et al., 2021) and acknowledges the complementary nature of DfX and PCC in a construction industry setting.

The managerial implications of this study include the proposed framework for PCC in the construction industry—what needs to be done in practice, and how. The proposed PCC process is also validated in conceptual level into companies use. As a basis, the operation model of the company needs to be in place, including defined products and processes, which need to be standardized to reduce the variation and to improve the efficiency (Annunen and Haapasalo, 2022). There is a clear need to understand the importance of the design phase across collaborative projects. Planning and managing capability creation of the production phase is essential in construction projects, and it is essential that the stakeholder tasked with leading production is responsible for creating capabilities for production. PCC enables avoiding the types of waste listed by Halttula, et al. (2017), thereby improving cost efficiency. In principle, PCC can be initiated for rapid benefits by agreeing to requisite roles and actively managing essential activities from the design phase onwards, tying activities into relevant milestones. At the same time, construction companies can directly contribute to the design of the building.

Conclusions

Among the shortages in the construction industry, which is causing productivity challenges, is the lack of efficient cooperation among the stakeholders and between the design and production phases. This results in failure to make full use of the available capabilities during both phases, causing excessive production costs. Collaborative methods are increasingly replacing traditional project management methods in construction, improving communication between participating companies and project phases. To improve productivity, lean methods such as big room and innovation workshops are increasingly utilized in collaborative construction, along with supply chain management principles. In combination with existing DfX methods, these form a viable basis for capability creation practices in the construction industry that will improve the design phase and ensure a smooth and efficient production phase.

The production challenges that require preplanning in the design phase to ensure an efficient production phase, were depicted in an analysis of construction project stakeholders. More detailed descriptions of these twelve issues were also elaborated. Then these challenges were further converted into elements across three main areas for PCC. Collaboration capability creation refers to managing multiple stakeholders during production, production process capability creation is dedicated to more technical and detail-related activities, and sourcing capability creation focuses on a growing number of subcontractors and suppliers. At a practical level, PCC needs to be managed by a dedicated owner, such as a production capability manager, through a milestone model for iteratively progressing processes. It is important to notice, that with a production capability manager, the production process is responsible for implementing PCC parallel to the design process.

This study is based on selected construction project stakeholders in a certain market. They have been operating on the same project and therefore are competent to collaboratively recognize and solve challenges. Naturally, these findings cannot be fully generalized; however, they are in line with existing literature on construction, and CC in other industries. The limitation of the study is, that these results apply in Finland, and conceptual level comparative studies should be done in other countries and regions. Presented PCC process is covering the key areas and activities of the PCC, but the actual detailed specific activity planning for each milestone needs to be done in each project. The follow-up studies should dive more deeply into these detailed areas of PCC, and the phenomena should be studied in completely different market areas. On a final note, the whole construction industry is still learning how to implement collaborative project methods in the most efficient and effective way.

References

Aapaoja, A., Herrala, M., Pekuri, A. and Haapasalo, H., 2013. The characteristics of and cornerstones for creating integrated teams. International Journal of Managing Projects in Business, [e-journal] 6(4), pp.695-713. https://doi.org/10.1108/IJMPB-09-2012-0056

Aapaoja, A. and Haapasalo, H., 2014. A framework for stakeholder identification and classification in construction projects. Open Journal of Business and Management, [e-journal] 2(1), pp.43-55. https://doi.org/10.4236/ojbm.2014.21007

AlMunifi, A.A. and Almutairi, S. 2021. Lessons Learned Framework for Efficient Delivery of Construction Projects in Saudi Arabia. Construction Economics and Building, [e-journal] 21(4). https://doi.org/10.5130/AJCEB.v21i4.7858

Annunen, P., Mustonen, E., Harkonen, J. and Haapasalo, H., 2021. Sales capability creation during new product development – early involvement of sales. Journal of Business & Industrial Marketing, [e-journal] 36(13), pp.263-73. https://doi.org/10.1108/JBIM-06-2020-0274

Annunen, P. and Haapasalo, H., 2022. Industrial operation model for the construction industry. International Journal of Construction Management. [e-journal] https://doi.org/10.1080/15623599.2022.2092810

Baiden, B.K., Price, A.D.F. and Dainty, A.R.J., 2006. The extent of team integration within construction projects. International Journal of Project Management, [e-journal] 24(2), pp. 13-23. https://doi.org/10.1016/j.ijproman.2005.05.001

Børve, S., Rolstadås, A., Andersen, B. and Aarseth, W., 2017. Defining project partnering. International Journal of Managing Projects in Business, [e-journal] 10(4), pp.666-99. https://doi.org/10.1108/IJMPB-10-2016-0076

Bresnen, M. and Marshall, N., 2000. Partnering in construction: A critical review of issues, problems and dilemmas. Construction Management and Economics, [e-journal] 18(2), pp.229-37. https://doi.org/10.1080/014461900370852

Bryman, A. and Bell, E., 2011. Business research methods. 3rd ed. Oxford: Oxford University Press.

Christopher, M., 2011. Logistics & supply chain management. 4th ed. Harlow: Financial Times Prentice Hall.

Clifford, N., Cope, M., Gillespie, T. and French, S., 2016. Key methods in geography. Thousand Oaks: SAGE Publications.

De Blois, M., Lizarralde, G., De Coninck, P., 2016. Iterative project processes within temporary multi-organizations in construction: The self-, eco-, re-organizing projects. Project Management Journal, [e-journal] 47(1), pp.27-44. https://doi.org/10.1002/pmj.21560

Denzin, N. and Lincoln, Y., 2005. Handbook of Qualitative Research. SAGE Publications.

Dixit, S., Mandal, S.N., Thanikal, J.V. and Saurabh, K., 2019. Evolution of studies in construction productivity: A systematic literature review (2006–2017). Ain Shams Engineering Journal, [e-journal] 10(3), pp.555-64. https://doi.org/10.1016/j.asej.2018.10.010

Duriau, V., Reger, R. and Pfarrer, M., 2007. A content analysis of the content analysis literature in organization studies: Research themes, data sources, and methodological refinements. Organizational Research Methods, [e-journal] 10, pp.5-34. https://doi.org/10.1177/1094428106289252

Dyer, J.H., Cho, D.S. and Cgu, W., 1998. Strategic supplier segmentation: The next ‘best practice’ in supply chain management. California Management Review, [e-journal] 40(2), pp.57-77. https://doi.org/10.2307/41165933

Fawcett, S.E. and Magnan, G.M., 2002. The rhetoric and reality of supply chain integration. International Journal of Physical Distribution & Logistics Management, [e-journal] 32(5), pp.339-61. https://doi.org/10.1108/09600030210436222

Fulford, R. and Standing, C., 2014. Construction industry productivity and the potential for collaborative practice. International Journal of Project Management, [e-journal] 32(2), pp.315–26. https://doi.org/10.1016/j.ijproman.2013.05.007

Gerth, R., Boqvist, A., Bjelkemyr, M. and Lindberg B., 2013. Design for construction: Utilizing production experiences in development. Construction Management and Economics, [e-journal] 31(2), pp.135-50. https://doi.org/10.1080/01446193.2012.756142

Halttula, H., Aapaoja, A. and Haapasalo, H., 2015. The contemporaneous use of building information modeling and relational project delivery arrangements. Procedia Economics and Finance, [e-journal] 21, pp.532-39. https://doi.org/10.1016/S2212-5671(15)00209-9

Halttula, H., Haapasalo, H., Aapaoja, A. and Manninen, S., 2017. Early involvement and integration in construction projects: The benefits of DfX in elimination of wastes. International Journal of Management, Knowledge and Learning, 6(2), pp.215-37.

Halttula, H., Haapasalo, H. and Silvola, R., 2020. Managing data flows in infrastructure projects - The lifecycle process model. Journal of Information Technology in Construction, [e-journal] 25, pp.193-211. https://doi.org/10.36680/j.itcon.2020.012

Herrera, R.F., Mourgues, C., Alarcón, L.F. and Pellicer, E., 2020. An Assessment of Lean Design Management Practices in Construction Projects. Sustainability, [e-journal] 12(1). https://doi.org/10.3390/su12010019

Hietajärvi, A-M., Aaltonen, K. and Haapasalo, H., 2017a. Managing integration in infrastructure alliance projects: Dynamics of integration mechanisms. International Journal of Managing Projects in Business, [e-journal] 10(1), pp.5-31. https://doi.org/10.1108/IJMPB-02-2016-0009

Hietajärvi, A-M., Aaltonen, K. and Haapasalo, H., 2017b. Opportunity management in large projects: A case study of an infrastructure alliance project. Construction Innovation, [e-journal] 17(3), pp.340-362. https://doi.org/10.1108/CI-10-2016-0051

Kang, M., Lee, G., Hwang, D.W., Wei, J. and Huo, B., 2021. Effects of cross-functional integration on NPD success: mediating roles of customer and supplier involvement. Total Quality Management & Business Excellence, [e-journal] 32(13-14), pp.1515-31. https://doi.org/10.1080/14783363.2020.1736543

Khan, S., 2015. An overview of constructability: A management tool for architects. Architecture Research, [e-journal] 5(5), p.125-39. https://doi.org/10.5923/j.arch.20150505.01

Kleinsmann, M., Deken, F., Dong, A. and Lauche, K., 2012. Development of design collaboration skills. Journal of Engineering Design, [e-journal] 23(7), pp.485-506. https://doi.org/10.1080/09544828.2011.619499

Kohlbacher, M. and Gruenwald, S., 2011. Process ownership, process performance measurement and firm performance. International Journal of Productivity and Performance Management, [e-journal] 60(7), pp.709-20. https://doi.org/10.1108/17410401111167799

Koskela, L., 2004. Making-do – The eight categories of waste. 12th Annual Conference of the International Group for Lean Construction. Helsingor, Denmark.

Lahdenperä, P., 2012. Making sense of the multi-party contractual arrangements of project partnering, project alliancing and integrated project delivery. Construction Management and Economics, [e-journal] 30(1), pp.57-79. https://doi.org/10.1080/01446193.2011.648947

Larsen, J.K., Lindhard, S.M., Brunoe, T.D. and Jensen, K.N., 2018. The Relation between Pre-planning, Commissioning and Enhanced Project Performance. Construction Economics and Building, [e-journal] 18(2), pp.1-14. https://doi.org/10.5130/AJCEB.v18i2.5762

Lehto, J., Harkonen, J., Haapasalo, H., Belt, P., Mottonen, M. and Kuvaja, P., 2011. Benefits of DfX in requirements engineering. Technology and Investment, [e-journal] 2(1), pp.27-37. https://doi.org/10.4236/ti.2011.21004

Love, P.E.D., Irani, Z. and Edwards, D.J., 2004. A seamless supply chain management model for construction. Supply Chain Management, [e-journal] 9(1), pp.43-56. https://doi.org/10.1108/13598540410517575

Lu, W., Tan, T., Xu, J., Wang, J., Chen, K., Gao, S. and Xue, F., 2021. Design for manufacture and assembly (DfMA) in construction: The old and the new. Architectural Engineering and Design Management, [e-journal] 17(1-2), pp.77-91. https://doi.org/10.1080/17452007.2020.1768505

McDermotti, P. and Khalfan, M., 2012. Achieving Supply Chain Integration within Construction Industry. Construction Economics and Building, [e-journal] 6(2), pp.44-54. https://doi.org/10.5130/AJCEB.v6i2.2983

Mesa, H.A., Molenaar, K.R. and Alarcón, L.F., 2019. Comparative analysis between integrated project delivery and lean project delivery. International Journal of Project Management, [e-journal] 37(3), pp.395-409. https://doi.org/10.1016/j.ijproman.2019.01.012

Meng, X., 2013. Change in UK construction: Moving toward supply chain collaboration. Journal of Civil Engineering and Management, [e-journal] 19(3), pp.422–432. https://doi.org/10.3846/13923730.2012.760479

Ohno, T., 1988. Toyota production system: Beyond large-scale production. Cambridge: Productivity Press.

Palinkas, L.A., Horwitz, S.M., Green, C.A., Wisdom, J.P., Duan, N. and Hoagwood, K., 2015. Purposeful sampling for qualitative data collection and analysis in mixed method implementation research. Administration and Policy in Mental Health and Mental Health Services, [e-journal] 42, pp.533-44. https://doi.org/10.1007/s10488-013-0528-y

Papadonikolaki, E., Vrijhoef, R. and Wamelink, H., 2016. The interdependences of BIM and supply chain partnering: Empirical explorations. Architectural Engineering and Design Management, [e-journal] 12(6), pp.476–94. https://doi.org/10.1080/17452007.2016.1212693

Pekuri, A., Haapasalo, H. and Herrala, M., 2011. Productivity and performance management – managerial practices in construction industry. International Journal of Performance Measurement, 1(1), pp.39-58.

RT103239, 2020. Allianssimalli hankkeen toteutusmuotona. Allianssimallin yleiskuvaus (Project alliance as a project method in Finnish construction industry). Rakennustieto.

Ross, J., 2003. Introduction to project alliancing. Alliance Contracting Conference. 30 April 2003. Sydney: Project Control International., Sydney. pp.1-42.

Saad, M., Jones, M. and James, P., 2002. A review of the progress towards the adoption of supply chain management (SCM) relationships in construction. European Journal of Purchasing & Supply Management, [e-journal] 8(3), pp.173-83. https://doi.org/10.1016/S0969-7012(02)00007-2

Sarhan, J., Xia, B., Fawzia, S., Karim, A. and Olanipekun, A., 2018. Barriers to implementing lean construction practices in the Kingdom of Saudi Arabia (KSA) construction industry. Construction Innovation, [e-journal] 18(2), pp.246-72. https://doi.org/10.1108/CI-04-2017-0033

Succar, B., 2009. Building information modelling framework: A research and delivery foundation for industry stakeholders. Automation in Construction, [e-journal] 18(3), pp.357-75. https://doi.org/10.1016/j.autcon.2008.10.003

Teo, A. L. E., Ofori, G., Tjandra, I. K. and Kim, H., 2016. Design for safety: theoretical framework of the safety aspect of BIM system to determine the safety index. Construction Economics and Building, [e-journal] 16(4), pp.1-18. https://doi.org/10.5130/AJCEB.v16i4.4873

Teräväinen, V.J. and Junnonen, J.-M., 2019. The promoters and the barriers for organizational culture change in a Finnish construction company. Construction Innovation, [e-journal] 19(4), pp.672-88. https://doi.org/10.1108/CI-04-2019-0029

Tolonen, A., Haapasalo, H., Harkonen, J. and Verrollot, J., 2017. Supply chain capability creation – The creation of the supply chain readiness for a new product during product development process. International Journal of Production Economics, [e-journal] 194, pp.237-45. https://doi.org/10.1016/j.ijpe.2017.09.007

Verrollot, J., Tolonen, A., Harkonen, J. and Haapasalo, H., 2017. Supply capability creation process: Key milestone criteria and activities. Journal of Industrial Engineering and Management, [e-journal] 10(3), pp.495-521. https://doi.org/10.3926/jiem.2375

Walker, D., 2018. Integrating project delivery. International Journal of Managing Projects in Business, [e-journal] 11(2), pp.548-54. https://doi.org/10.1108/IJMPB-05-2018-166

Womack, J.P. and Jones, D.T., 2003. Lean thinking. Banish waste and create wealth in your corporation. New York: Free Press.

Yeganeh, A.A., Azizi, M. and Falsafi, R., 2019. Root causes of design-construction interface problems in Iranian design-build projects. Journal of Construction Engineering and Management, [e-journal] 145(12). https://doi.org/10.1061/(ASCE)CO.1943-7862.0001727

Appendix 1

Questionnaire

Basics

1. Name of the case company

2. Role of the case company in the alliance project(s)

3. Role of the interviewee

Background questions

4. Alliance model–related experiences in the company:

• How many and what alliance projects you have participated in?

• What differences were there in past alliance projects?

5. Do you have alliance model process descriptions in use?

• Are you using takt time production?

• Are you using big room?

• Are you using last planner?

• Are you using other lean/alliance model–related processes/methods?

6. How does your alliance model work with other construction project–related processes and methods in your company?

7. Which other processes and methods are in use in your company as the basis of your construction project work?

Key questions

8. Which issues require preplanning and preparation in the alliance project development phase (KAS) to ensure an implementation phase (TAS) that is as good as possible? (E.g., Time management (takt time-based manufacturing), procurement/purchasing, site logistics, construction, costs, quality, risk management, organization structure.)

9. Which issues have caused problems in the implementation phase (TAS)?

10. How would you resolve those issues?

11. What are the key targets and metrics in your current alliance project(s)?

12. How are you following up and measuring whether you have reached your targets?

13. Are there any other issues that you would like to mention related to discussed topics and interview?