RESEARCH ARTICLE

A project management framework for enhanced productivity performance using building information modelling

Longhui Liao*1, Evelyn Ai Lin Teo1, Sui Pheng Low1

1Department of Building, National University of Singapore, 4 Architecture Drive, Singapore 117566.

Construction Economics and Building Vol. 17, No. 3 September 2017

© 2017 by the author(s). This is an Open Access article distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0) License (https://creativecommons.org/licenses/by/4.0/), allowing third parties to copy and redistribute the material in any medium or format and to remix, transform, and build upon the material for any purpose, even commercially, provided the original work is properly cited and states its license.

Citation: Liao, L., Teo, E.A.L., and Low, S.P. 2017. A project management framework for enhanced productivity performance using building information modelling. Construction Economics and Building, 17:3, 1-26. http://dx.doi.org/10.5130/AJCEB.v17i3.5389

ISSN 2204-9029 | Published by UTS ePRESS | ajceb.epress.lib.uts.edu.au

*Corresponding author: Longhui Liao, Department of Building, National University of Singapore, 4 Architecture Drive, Singapore, 117566, E-mail: a0109736@u.nus.edu

DOI: http://dx.doi.org/10.5130/AJCEB.v17i3.5389

Article History: Received 07/02/2017; Revised 17/07/2017; Accepted 22/07/2017; Published 21/09/2017

Abstract

Although the Singapore government has mandated submissions of building plans in building information modelling (BIM) format since July 2013, this does not yet seem to lead to enhanced productivity performance. BIM collaboration between designers and downstream contractors appears to remain inadequate. While many studies have been conducted on using BIM for better project outcomes, studies that relate BIM with the identification of non-value adding activities in the project lifecycle and the reduction of the resulting wastes are at infancy stage. This paper aims to propose a project management framework for enhancing the productivity of building projects in Singapore, which forms Phase I of an ongoing research project. A two-pronged approach is presented. Firstly, non-value adding activities in the current project delivery process that uses BIM partially in Singapore are identified by comparing the typical current process with full BIM-based processes; such activities are cut down after process transformation in terms of people, process, and technology. Secondly, time savings derived from reducing the wastes caused by these activities are quantified. The proposed framework was validated by a case study of a local residential project. It was concluded that this framework provides a valuable tool for project teams to enhance productivity performance.

Keywords

productivity, building information modelling (bim), process transformation, non-value adding activities, wastes

Introduction

Productivity performance is not only a determinant of a firm’s long-term viability, but also a benchmark of overall competitive advantage of an industry and an economy. Since many countries have suffered from suboptimal productivity performance in the construction industry, much research work needs to be done to formulate strategies for productivity enhancement (Ranasinghe, Ruwanpura and Liu, 2011).

Singapore’s Economic Strategies Committee (ESC, 2010) reported that there was significant room to improve productivity in every sector of Singapore’s economy. Therefore, the Singapore government targeted to achieve productivity growth of 2–3% per year from 2010 to 2020 (ESC, 2010), which is measured by labor productivity in terms of value-added per employee. To meet this target, the first Construction Productivity Roadmap (CPR) was formulated in 2010, which focused on helping firms to adopt technology, according to Singapore’s Building and Construction Authority (BCA, 2011a). Strict legislations have been enforced in this CPR, such as formulating a 5-year BIM adoption roadmap. BIM electronic submission (e-submission) for regulatory approval has been mandated in three phases. New building projects with a Gross Floor Area (GFA) of 20,000 m2 and above were required to submit their architectural plans in BIM format since July 2013 and to submit their structural and mechanical, electrical, and plumbing (MEP) plans in BIM format since July 2014. Eventually, all new building projects with a GFA of 5,000 m2 and above were required to make architectural, structural, and MEP BIM e-submissions since July 2015 (BCA, 2011b).

Nevertheless, the target had not been completely realized by 2015. The Singapore Department of Statistics (SDOS, 2016) reported that the year-on-year changes of labor productivity were 2.3% (2011), -0.3% (2012), 0.5% (2013), -0.5% (2014), and -0.1% (2015) for the total economy; the figures for the construction industry were 2.0% (2011), 2.7% (2012), -3.0% (2013), -1.8 % (2014), and 0.5% (2015), respectively. Furthermore, even if the productivity performance in the construction industry is good enough to achieve the target, productivity performance enhancing tools such as BIM will still be needed to make the productivity better. To meet this need, the second CPR was formulated in 2015 (BCA, 2015), which focuses on upgrading the skills of the construction workforce, driving collaboration among firms, and integrating the construction value chain. Virtual design and construction (VDC) and design for manufacture and assembly (DfMA) are highlighted as good approaches and supported by the second BIM roadmap in this CPR. The literature search also suggests that integrated project delivery (IPD) will be a good approach to meet the productivity growth expectations.

As can be seen from the above, there is a need to transform the Singapore construction industry, and one of the useful tools in this transformation would be BIM (Nath et al., 2015). It is process transformation that validates BIM implementation in the construction industry (Arayici et al., 2011; Autodesk, 2012; Khosrowshahi and Arayici, 2012; Enegbuma, Aliagha and Ali, 2014). Researchers (Lee et al., 2005; Lee and Sexton, 2007) studied the process transformation in terms of People, Process, and Technology. Lee and Sexton (2007) explored the feasibility of industry absorbing and diffusing n-dimensional (nD) modelling technology and found that there ought to be intrinsic links between Technology, People, and Process. They reported that although People appreciate the potential significant benefits of nD modelling technology, it could be too embryonic and too far removed from the “comfort zones” of construction firms because it requires heavy investment and contains too many risks. This echoes sentiment in studies concentrating on the Singapore construction industry (Teo and Heng, 2007; Teo, 2008).

The situation and the above findings inspired the present authors to develop a BIM-based process transformation (BBPT) model to enhance the productivity in the Singapore construction industry. Therefore, an ongoing research project lasting for four years is conducted to fill this gap. In this study, People refers to key project stakeholders including government agencies, owners, architects, engineers, general contractors, key trade contractors, manufacturers/suppliers, and facility managers; Process refers to work processes that constitute traditional project delivery process, current project delivery process, and full BIM-based processes; Technology refers to BIM-related tools. In addition, researchers normally measure productivity improvement in terms of time saving (Chelson, 2010; Nath et al., 2015). But from a broader perspective, the time saving is derived from the identification of wastes such as defects, reworks, overproduction, waiting time, requests for information (RFIs), unnecessary inventory (Ohno, 1988; Chelson, 2010; Wu, Low and Jin, 2013; Nikakhtar et al., 2015), and safety issues (Alwi, Hampson and Mohamed, 2002).

Five research problems have been identified in the larger study after the literature review. Firstly, the productivity performance needs to be enhanced. Secondly, the current industry practices in the project lifecycle in the Singapore construction industry were not identified. In the context of the mandatory BIM e-submissions, People concentrate too much on the design stage, rather than full BIM adoption in the project lifecycle. Thirdly, the process wastes produced by People in the current process and leading causes of the wastes were not established. It is suggested that a good way to reduce the wastes could be to establish the concept of non-value adding activities and to remove such activities in the project lifecycle (Wu and Low, 2011; Wu, Low and Jin, 2013; Nikakhtar et al., 2015). Next, critical factors driving and hindering People to change towards the full BIM-based processes were not identified and analyzed in tandem with the concept of process transformation. Finally, the BBPT model in terms of People, Process, and Technology for the current process was not developed.

A collaborative atmosphere for BIM implementation among project teams may not exist in the short term, so the construction industry must take steps to change the unproductive current practices to save time. Thus, this larger study aims at developing a BBPT model to assist project teams in reducing wastes, and thus enhancing the productivity performance of building projects in Singapore. Accordingly, the main objectives of this study are to:

- Study the current industry practices in the project lifecycle;

- Identify the non-value adding activities in the current industry practices, study the leading causes, and evaluate their impact on productivity;

- Study the experiences of People when using BIM in their past, similar building projects in Singapore;

- Investigate the drivers that motivate People to change and the hindrances that People are likely to face;

- Develop a BBPT model from the perspectives of People, Process, and Technology for the current process in Singapore.

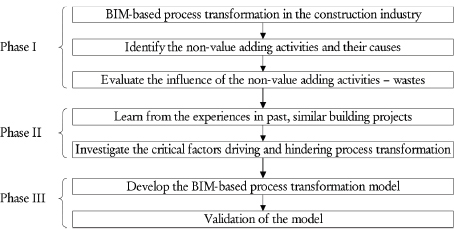

Figure 1 presents the phasing of the entire study which focuses on applying BIM to help People transform their current processes into full BIM-based processes in building projects in Singapore. Although the full BIM-based process can be discussed from many perspectives, this study focuses on VDC, DfMA, and IPD, from the conceptualization phase to the facility management (FM) phase. VDC and DfMA are encouraged by the local government; IPD has been proven to be productive in some projects and has gained popularity overseas, especially in north America (Cohen, 2010).

Figure 1 Phasing of an ongoing research project

This paper concentrates on Phase I of the larger study. Issues related to Phase II and Phase III are beyond the scope of this paper and there are plans to publish their corresponding findings in other papers. This paper proposes a framework for People to enhance the productivity in their building projects in Singapore. By identifying the non-value adding activities and reducing the resulting wastes, time savings can be obtained, enhancing productivity.

Evolution of project delivery processes

TRADITIONAL PROCESS

Traditionally, People used computer-aided design (CAD) programs, and architectural and engineering contracts were solely awarded before construction (Azhar, Kang and Ahmad, 2014). Hence design was not totally fixed until the construction phase because trade contractor input is not available until then, according to the American Institute of Architects and the American Institute of Architects, California Council (AIA and AIACC, 2007). Due to this disconnection, contractors had to reproduce drawings and FM team uses 2D as-built drawings to manage buildings. This process results in frequent claims and disputes between People as well as cost and time overruns. Therefore, the construction industry needed alternative delivery methods.

CURRENT PROCESS IN SINGAPORE

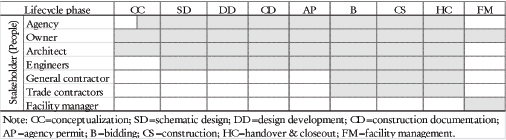

Azhar, Kang and Ahmad (2014) advocated using more integrated approaches to overcome the fragmentation issue in the traditional process. The Singapore government has mandated the architectural and engineering BIM e-submissions, driving BIM adoption in the construction industry (see Figure 2). Despite this, the BIM adoption stresses on the design stage, where on-site activities do not begin. Lam (2014) reported that the contractors and facility managers are not involved in the design phases to contribute their knowledge. The architects and engineers tend to use design models only for their own benefits such as applying for the regulatory approvals, and may not consider the BIM uses of downstream parties and share their quality BIM models. Hence general contractors must re-build the BIM models based on the 2D drawings, specifications, and incomplete design models from the designers to coordinate key trades, produce shop drawings, and develop and submit as-built BIM models to the architects during construction. Furthermore, most trade contractors lack BIM skills and facility managers rarely use BIM.

Figure 2 People involvement of different phases in the typical current process in the Singapore construction industry (Adapted from Lam, 2014)

Overall, it is a partial BIM process currently adopted in Singapore. If the designers do not collaborate with the downstream parties, the true spirit of BIM will not be realized as it results in fragmented BIM uses between the designers, contractors, and facility managers. As a result, there will be many problems in the construction and the FM phases, such as frequent RFIs, change orders, and reworks. It is hence necessary to develop suitable strategies to drive for better BIM collaboration throughout the construction value chain.

SHORTCOMINGS IN CURRENT PROCESS – DEVELOPING NEW PROCESSES

The fragmentation in the current process inhibits a widespread change in the construction industry. In most projects People work in silos on their own BIM models as they do not have a precise knowledge of the potential value of full BIM adoption. Little attempt has been made to share BIM models in building projects in Singapore (Lam, 2014). People seek change, but do not want to be changed (Senge, 1990). It is hence imperative to explore appropriate delivery methods to eliminate the information fragmentation between People in different phases. To achieve this, a change is required from the existing approach which is based on individual uses to an integrated approach which provides quality information of BIM models among People in the project lifecycle. In addition, the alignment of participating firms’ activities with project outcomes is needed. BIM tools are ready and available to enable new ways of working that result in more predictable and accurate project outcomes (Autodesk, 2008). With BIM as a facilitator, approaches such as IPD, VDC, and DfMA are increasingly used in the construction industry worldwide.

IPD

IPD has emerged as a solution to the information fragmentation (Azhar, Kang and Ahmad, 2014). It can reduce the inefficiencies and wastes that are embedded in the current design and construction practices (Kent and Becerik-Gerber, 2010). Researchers (AIACC, 2014; Azhar, Kang and Ahmad, 2014) identified the following key characteristics that distinguish IPD from other processes:

- Continuous involvement of an owner and key designers and contractors from early design through project completion;

- A multi-party agreement that clearly defines their roles and responsibilities;

- Alignment of business interests through shared risks/rewards;

- The IPD team collectively and clearly defines achievable goals and benchmarks for measuring them;

- Joint project control by the IPD team according to predetermined criteria;

- IPD team members waive any claim amongst themselves except for in the instance of a wilful default.

BIM is central to the process changes that IPD would bring in the construction industry, according to Autodesk (2008) which explained how the use of BIM in an integrated environment enables the IPD working process and results in more predictable and accurate outcomes. Eastman et al. (2011) revealed that BIM forms the foundation for better collaboration among People. A subsequent study examined how BIM can be useful to help achieve the above IPD characteristics (Azhar, Kang and Ahmad, 2014); this said study found that there are direct relationships between BIM attributes and IPD characteristics so that BIM would be a catalyst for IPD implementation. Nevertheless, the full potential of BIM will not be realized unless there are structural changes in the current process.

AIACC (2014) explained the commonly-used IPD process overseas, which saw that expertise from both the design team and the construction team is available throughout the design phases. Despite this, the process needs to be adapted for Singapore use. Using the phasing and People involvement of the current process in Figure 2 as a reference, this paper highlighted the following changes in the IPD process: (1) changing the agency permit phase to agency review phase and moving it forward to be concurrent with the design phases and the construction documentation phase; (2) involving the general contractor since the conceptualization phase, as well as the key trade contractors and the facility manager from early design onwards; and (3) changing the bidding phase to final buyout phase. The agency review phase commences in the criteria design (schematic design) phase and increases in intensity during the final review period. As policy-makers, the local government agencies actively participate from the beginning. Singapore’s CORENET is a major initiative to facilitate electronic building plans submission, checking, and approval processes (Smith, 2014; Solihin and Eastman, 2015), which allows the agencies to automatically analyze and check the models submitted for program and code compliance (Eastman et al., 2011; Khosrowshahi and Arayici, 2012). The BIM use and early involvement and validation by the agencies minimize agency comments and required changes to the designs as submitted (AIA and AIACC, 2007). The general contractor and trade contractors are also involved to contribute site knowledge in design and submittal preparation (Kent and Becerik-Gerber, 2010). In addition, the final buyout phase completes the buyout of remaining contracts such as trade contractors not involved during the design phases and materials without long lead time (AIACC, 2014).

VDC

VDC is an approach for the designers and the contractors working together as a collaborative team to build, visualize, analyze, and evaluate project performance on multi-disciplinary models in the design stage before tremendous time and resources are consumed during construction (Chua and Yeoh, 2015). Kunz and Fischer (2012) suggested three stages of VDC implementation:

- Firstly, visualization. The project team creates BIM models to perform design, construction, and operations based on performance metrics, such as buildability and constructability, that are predicted from the models and tracked in the process. This stage is commonly-used within the global construction industry.

- Secondly, integration. The project team members reliably share discipline specific data between disparate modelling and analysis applications by using Industry Foundation Classes (IFC). For example, an integrated set of design models of different disciplines can be created based on a shared IFC-based architectural model.

- Thirdly, automation. The project team uses automated methods to perform routine design tasks or to build subassemblies in a factory. For instance, design detailing can be automated using knowledge from design codes (Chua and Yeoh, 2015), and standard building products can be integrated in the design development phase by the contractors to increase off-site prefabrication and assembling (Gao and Fischer, 2006). The standard products will appear in the schedule with the precise style and specifications for manufacturing.

Fischer et al. (2014) found that the visualization and simulation are the engine of VDC. Visualization is an effective way for the team members to describe themselves accurately and to analyze their work and that of others; therefore, the team can communicate more clearly with each other, and with the owner. Simulation also allows the team to make better predictions by showing how close different design options come to desired outcomes, and the consequences of their decisions. The automation will be realized based on the good visualization and integration (Kunz and Fischer, 2012).

Gao and Fischer (2006) studied VDC with 11 case projects in Finland. This paper also adapted them into a VDC process to the Singapore context. Compared with the phasing and People involvement of the current process in Figure 2, this paper changed the bidding phase to the final buyout phase and moved the bidding phase to where the design stage starts, so that the contractors could participate and input their construction expertise throughout the design phases. In addition, the structural and MEP engineers could aid the architects in the architectural modelling in the schematic design stage and then take advantages of the information from the architectural model for their own analysis. The structural engineer uses the model as a base to make strength calculations for the preliminary framing plan and compare different structural frame options. The MEP engineers conduct a computerized analysis of 3D spatial model and set realistic targets such as sizing for building systems. These engineers comment on the architectural model with respect to the more complicated systems, and develop structural and MEP models after the architectural model is almost fixed. Also, the general contractor uses the models shared by the architects and engineers as bases to build its construction model (Gao and Fischer, 2006; Porwal and Hewage, 2013).

DfMA

DfMA concentrates on developing a design that is optimized for off-site manufacture (OSM) of discrete sections of the final facility and on-site assembly of them after being transported to site, essentially moving site-based activities into a controlled factory environment (McFarlane and Stehle, 2014). The DfMA approach consists of three major components:

- Geometry (3D model). It allows the team members to visually understand and interrogate the design intent and mainly includes the engineers’ finite element models and fabrication models that enable automated production of standard building elements. The models are also used to produce 2D drawings for non-automated processes such as the regulatory approvals and third-party manufacture of small elements.

- Production (OSM). The entire fit-out process, namely the manufacture and assembly of structural and MEP modules of different scales as well as the decorative elements, can be carried out in the factory environment.

- Metadata (BIM). It contains all relevant project parameters. Multiple design analyses can be conducted, such as calculating and predicting the impacts of time, sequencing, scheduling, costs, sustainability, constructability and so on, allowing the team to select the best design option (McFarlane and Stehle, 2014).

The basis of DfMA is the virtual reality modelling of the building, which includes four significant elements, namely the discretization of the construction, 3D design collaboration, 4D construction planning, and 5D costing. All the elements should be interrogated and improved by the project team members until the optimum solution is reached (McFarlane and Stehle, 2014), allowing People to participle interactively in the design and planning phases (Gibb and Isack, 2003). This ensures that all the project parameters are met prior to commencing actual construction.

To adopt DfMA successfully, the construction industry must make fundamental structural changes based on a thorough understanding of the principles underpinning the manufacturing industry (Blismas and Wakefield, 2009). DfMA changes the way People work, both in terms of the Process and product. Based on the literature on DfMA and BIM, the DfMA process can be adapted for the Singapore construction industry. Using the phasing and People involvement of the current process in Figure 2 for reference, this paper placed emphasis on the following changes in the DfMA process: (1) changing the bidding phase to the final buyout phase and locating the bidding phase after the conceptualization phase; (2) adding and highlighting the manufacturers (suppliers) in the list of the key stakeholders; and (3) dividing the construction phase into four phases, namely manufacture, substructure, superstructure, and fit-out. Since design changes would be costly after the fabrication of standard building elements begins, the general contractor and the manufacturers are early involved to help develop the optimum design virtually and early whereby the superstructure and fitting out phases can take place off-site while or before ground works and substructure are being done on-site, compressing on-site phases. The bidding phase entails engaging the general contractor and the manufacturers prior to the design stage using a two-stage contract to avoid them working at risk financially before the construction phase. The subcontractors would be engaged in the final buyout phase to complete traditional construction, including ground works, substructure, and so on. It should be noted that the manufacturing team includes factory based operatives, site erection teams, and so on, and that such a team would also act as the general contractor if the conventional construction is not included in the project (Ross, Cartwright and Novakovic, 2006).

Field study and findings

This paper was divided into four stages. Firstly, the key activities related to BIM in each project delivery process in the Singapore construction industry and the potential resulting wastes that would seriously affect the productivity were identified through the literature review. Secondly, BIM experts in Singapore were approached to validate these key activities and wastes, either through personal interviews or via e-mail enquiries. The interviews were recorded and analyzed using content analysis. Wong, Salleh and Rahim (2014) also adopted this method which studied the BIM capabilities in quantity surveying in Malaysia. More importantly, a framework for enhancing the productivity performance in Singapore was proposed based on the identification of the non-value adding activities and the potential resulting wastes in a building project context. Finally, a case study was conducted to validate the proposed framework.

NON-VALUE ADDING ACTIVITIES

Previous studies (Wu and Low, 2011; 2012; Wu, Low and Jin, 2013; Wu and Feng, 2014) have identified the non-value adding activities in the precast-concrete production and installation processes in Singapore, which would increase carbon emissions. Such activities are wasteful because they consume the time of workers and other resources but do not add value to the complete process and the final product (Wu, Low and Jin, 2013; Nikakhtar et al., 2015).

In the Singapore context, the key activities related to BIM in building projects may be referred to in Table 1. It should be noted that the activities in Table 1 may not be comprehensive, but provide a good representation of the current uses of BIM within the Singapore construction industry. The BCA’s gap analysis of the first BIM roadmap revealed many problems in the current state of BIM adoption, such as firm-based rather than project-wide BIM collaboration (Lam, 2014). As mentioned earlier, the BIM uses currently adopted in Singapore were lonely or partially. Without knowing the downstream BIM uses, the design team may not be able to identify the reusable project information and important information exchanges (Anumba et al., 2010). Compared with the IPD, VDC, DfMA processes, this partial BIM adoption creates major non-value adding activities in the current process, which result in various wastes and consume time (Nikakhtar et al., 2015), leading to productivity loss.

| Phases | Processes | Key activities related to BIM |

|---|---|---|

| CC | Current | The owner and the architect set project requirements |

| IPD | The key stakeholders are engaged, form an IPD team by a multi-party contract, jointly set project goals and benchmarks, outline BIM goals and potential BIM uses (such as 4D modelling and model updating) based on the project characteristics, stakeholders’ goals and capabilities, and desired risk allocations, and identify the responsible stakeholders for the BIM uses and information exchanges; The team agrees on the reward/risk sharing arrangements |

|

| VDC/DfMA | The owner and the architect set project requirements and outline the BIM goals and potential BIM uses (such as 3D site analysis and code validation) based on the project characteristics | |

| SD (criteria design for IPD) |

Current | The architect and engineers create their design models with little collaboration and without the construction, fabrication, and facility management inputs from the downstream people |

| IPD | All key project parameters (such as scope, basic design, system selection, schedule, cost target, quality levels, prefabricated components, buildability, and constructability) are set; All the key trade contractors are engaged to input their site expertise |

|

| VDC | The design team and construction team agree on the multi-party collaboration contracts to share data, identify the data exchanges between the key firms, and define the exchange procedures and formats; The engineers and contractors work together with the architect to develop architectural model; the facility manager may also contribute to the design |

|

| DfMA | The engineers, general contractor, and manufacturers are engaged with two-stage contracts, further outline the BIM goals and potential BIM uses (such as 3D coordination and digital fabrication) according to their goals and capabilities as well as risk allocations, and identify the responsible parties for the BIM uses and the collaboration methods (such as regular meetings) of data exchanges; The engineers, general contractor, and manufacturers contribute in the architectural modelling |

|

| DD (detailed design for IPD) |

Current | The building elements may not be well defined; The building systems may not be coordinated until the construction phase |

| IPD | All the building systems are fully engineered and coordinated, with required level of detail | |

| VDC/DfMA | The engineers build the structural and MEP models based on the architectural model; The general contractor creates the construction model and fabrication model (if any) using the design models as bases |

|

| CD (implementation documents for IPD) |

Current | The design team produces 2D drawings and specifications for the downstream uses such as regulatory submission and tender documents preparation; Prefabrication of some building components cannot commence due to design uncertainties |

| IPD/VDC/DfMA | The contractors and manufacturers document the construction intent of the building systems and components to produce shop and/or fabrication drawings; The fabrication of the building systems, especially those long-lead items, begins as the design is fixed; The team generates documents for permitting, assembly, detailed schedule, and so on |

|

| AP (agency review for IPD) |

Current/ VDC/DfMA |

The designers apply for planning approvals in BIM format |

| IPD | Since the regulatory agencies participate actively in the design stage, the team applies for planning approvals and responds to the agency comments in parallel with the design stage | |

| B | Current | The designers only pass 2D drawings or incomplete design models to potential contractors |

| IPD | Since the key contractors have been engaged either in the conceptualization phase or in the design stage, this phase entails the buyout of remaining contracts such as the trade contractors not involved in design and materials without long lead time | |

| VDC | The trade contractors that were not involved in the design stage are engaged | |

| DfMA | Since the general contractor and manufacturers have been engaged in the early design stage, this phase engages the subcontractors to complete the conventional construction such as the ground works and substructure | |

| CS | Current | The general contractor re-builds the BIM models for construction uses and their own submissions; Due to the disconnection between the upfront and downstream parties, RFIs may be frequently raised for the designers to respond, and reworks need to be completed where necessary; A low percentage of building components would be prefabricated |

| IPD/VDC | The team uses the models to guide construction, and reviews and updates the models until completion | |

| DfMA | The manufacturers produce building systems and modules in the factory environment before or while the ground works and substructure are being done on-site | |

| HC | Current | The team may spend much time and many resources to resolve the disputes between the stakeholders |

| IPD | The team finalizes the as-built BIM models and specifications for facility management and resolves the risk and reward sharing arrangements | |

| VDC/DfMA | The team finalizes the as-built BIM models and specifications | |

| FM | Current | The facility management team uses 2D as-built drawings to manage the building unless the owner pays for the 3D as-built models |

| IPD/VDC/DfMA | The facility management team uses 3D as-built models as planned in the project beginning to manage the building | |

| Note: CC=conceptualization; SD=schematic design; DD=design development; CD=construction documentation; AP=agency permit; B=bidding; CS=construction; HC=handover & Closeout; FM=facility management. (Source: Adapted from Gibb and Isack, 2003; Gao and Fischer, 2006; Ross, Cartwright and Novakovic, 2006; AIA and AIACC, 2007; Anumba et al., 2010; Kunz and Fischer, 2012; BCA, 2013; Porwal and Hewage, 2013; AIACC, 2014; Lam, 2014; McFarlane and Stehle, 2014) |

||

WASTES

Non-value adding work held a considerable portion in most construction processes (Al-Sudairi, 2007; Nikakhtar et al., 2015). This work even exceeded 50% of the total work in some cases (Al-Sudairi, 2007). To quantify the impact of the non-value adding activities in the current process on the productivity, a total of 13 kinds of the potential resulting wastes that would be more impactful have been identified from the literature review (see Table 2).

| Waste | References | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | |

| Defects | x | x | x | x | x | x | x | ||||||||||

| RFIs | x | x | x | x | x | ||||||||||||

| Reworks/abortive works | x | x | x | x | x | x | x | ||||||||||

| Waiting time/idle time | x | x | x | x | x | x | x | x | x | ||||||||

| Change orders | x | x | x | ||||||||||||||

| Activity delays | x | x | x | x | x | ||||||||||||

| Overproduction/reproduction | x | x | x | x | x | x | x | x | x | x | |||||||

| Transporting/handling time | x | x | x | x | x | x | x | ||||||||||

| Unnecessary inventory | x | x | x | x | x | x | x | ||||||||||

| Excess processing | x | x | x | x | |||||||||||||

| Unnecessary movement of people and materials on site | x | x | x | x | x | ||||||||||||

| Design deficiencies (errors, omissions, additions) | x | x | x | x | |||||||||||||

| Safety issues (injuries) | x | x | x | x | |||||||||||||

| Note: (1) Abdel-Razek, Abd-Elshakour and Abdel-Hamid (2007); (2) Alarcon (1997); (3) Alwi, Hampson and Mohamed (2002); (4) Arayici et al. (2011); (5) Chelson (2010); (6) Chua and Yeoh (2015); (7) Eastman et al. (2011); (8) Ekanayake and Ofori (2004); (9) Formoso, Isatto and Hirota (1999); (10) Lee et al. (1999); (11) Nikakhtar et al. (2015); (12) Ohno (1988); (13) Senaratne and Wijesiri (2008); (14) Teo et al. (2014); (15) Wong, Salleh and Rahim (2014); (16) Wu and Low (2011); (17) Wu and Low (2012). | |||||||||||||||||

EMPIRICAL FINDINGS

To validate the key activities related to BIM and the potential resulting wastes, a total of 68 practitioners in Singapore were approached via e-mails. The practitioners were requested to comment on the readability, relevancy, accuracy, applicability, and comprehensiveness of the key activities and the wastes, as well as add and delete necessary items if rational. Finally, 16 responses were received, representing a response rate of 23.53% which was acceptable because it was even higher than the general response rate of Singapore surveys range of 10%–15% (Teo, Chan and Tan, 2007). Thus, the 16 responses from the e-mail enquiries were considered adequate and valuable to validate the activities and wastes identified in this paper. Of these, seven incoming e-mails commented on the activities and three on the wastes. Some of the comments were incorporated in this paper; for example, the comment “the design and construction data in digital models are less relevant for operations and maintenance, so the facility management team will still use 2D as-built drawings to manage buildings” was merged into the key activities in the current process in Table 1. Other comments that were less relevant to BIM or too drastic were omitted, such as “buildings are evolving and changes are inevitable, thus the use of BIM would be a waste of manpower just to update every day”.

Apart from the e-mail data, six BIM experts preferred being interviewed to discuss the BIM implementation in Singapore. The number of the interviews was adequate for validating the activities and wastes, compared with previous studies: Zhao, Hwang and Low (2016) validated the action plans for improving enterprise risk management implementation in Chinese construction firms based in Singapore by interviewing six experts; Wong, Salleh and Rahim (2014) validated the capabilities of BIM in quantity surveying practice by eight interviews. Although Wong, Salleh and Rahim (2014) interviewed two more experts, this said previous study did not conduct other validations such as the e-mail enquires as this paper did. All the six BIM experts were from large firms and had at least three-year experience of implementing BIM in building projects in Singapore. Table 3 presents a summary of the personal interviews. The interviews were semi-structured and the data were recorded and transcribed. Content analysis of the data outlined that the key activities in Table 1 were confirmed by the interviews. In addition, the waste “design errors” was changed to “design efficiencies” to also include design omissions and additions, and the waste “reworks” to “reworks and/or abortive works” that are widely-used in the local construction industry (see Table 2). Hence, it could be concluded that all the key activities in Table 1 and the potential resulting wastes in Table 2 were validated by the interviewees and e-mail exchanges.

The non-value adding activities and resulting wastes led to the suboptimal productivity in the current process in Singapore, which may be explained by the following reasons: (1) the rules and guidelines for driving BIM adoption in Singapore may not encapsulate the best available knowledge of BIM spirit. The BIM submission policy that most projects should comply with may not necessarily lead to expected consequences (Alter, 2015), especially in the short term when the local practitioners were shifting to a higher level of BIM readiness. The interviewee (I4) argued that such a policy itself might be wasteful because the submittals prepared in the design phase are at a higher level of detail and precision and cannot be reusable in the later stages of the project, and consume time and resources; instead, the project team may prefer incentives like extra GFA as more strong motivations to use BIM fully. Meanwhile, the proposed and codified IPD, VDC, and DfMA processes serve as suggestions and guidelines for the project team, but the required collaboration skills may not be available to the current team structure to fully implement such processes. So, the full benefits of BIM were not reaped; (2) the changes to the accustomed workflow emerged quite uncontrollably for many practitioners in Singapore (Markus and Robey, 1988). Although the government mandate and encouragement was gradually rolled out, many firms still did not adapt to or resisted to changes in the new way of working using BIM. For example, the small focus group reported that the MEP design models often had apparent design deficiencies, which would seriously harm the collaboration between the project participants and resulted in substantial RFIs and reproduction of the models by the contractors. Other designers may also not identify the downstream BIM uses when developing their models; and (3) in addition to the technology and technological processes, the contextual project factors in the Singapore construction industry could play critical roles (Barley, 1986). The e-mail exchanges data indicated that in the current market, the contract prices were too low for the MEP designers to put many resources in creating perfect digital design models. In addition, insufficient time was given to full design development; it was common that the detailed design proceeded concurrently with the construction phase which commenced after obtaining the regulatory approvals of the schematic design models. Furthermore, the project team members may face interoperability issues that different parties used various software or software versions. Hence, the productivity performance was not improved significantly as predicted, implying a steep learning curve of using BIM to transform the typical current process adopted in Singapore.

Framework to enhance productivity for project management

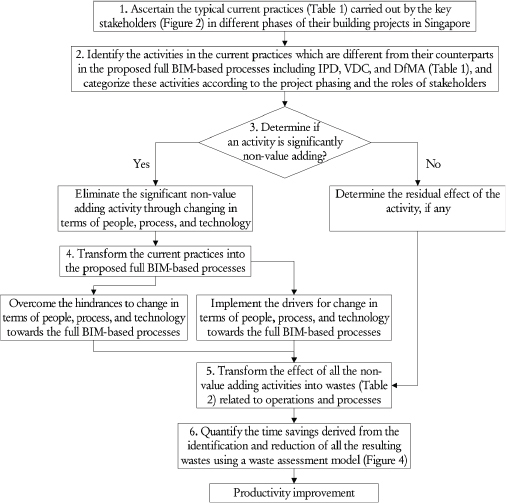

A project management framework for adopting the full BIM-based processes to enhance the productivity performance of building projects in Singapore is proposed, as shown in Figure 3. The basic purpose of developing this framework is to help project teams transform their project delivery processes for productivity gains.

Figure 3 Framework to enhance productivity for project management

The first step in this approach is to map and ascertain the corporate goals and typical current practices (BIM uses, processes, information exchanges, communication procedures, and so on) carried out by People in their building projects in Singapore. Normally when building a project team, all the key participants have documented their standard corporate practices of delivering services in the projects they have been working on. The key activities related to BIM in building projects in Singapore may echo sentiments in Table 1. They are not productive enough due to the partial use of BIM. Although the local government has been driving People to use BIM, the state of BIM adoption is uneven in the market (McGraw Hill Construction, 2014). The largest contractors tend to be very advanced to adopt BIM and thus reap the benefits more fully, whereas the others are in the beginning phase. Overall, the Singapore construction industry is not very BIM-ready for project-wide full collaboration among People at various phases of building projects (Lam, 2014).

The next step is to identify the activities in the current process that are different from their counterparts in the proposed full BIM-based process. This can be done by comparing the activities grouped in terms of project phasing in Figure 2 and Table 1. The activities in Table 1 may not be comprehensive, but provide a good representation of the current uses of BIM in the current, IPD, VDC, and DfMA processes. IPD relies on the collective expertise contributed by People throughout the project lifecycle; they are on the same productivity boat, leading to an ideal project delivery approach. VDC enables the contractors to detect problems virtually in the design stage, and thus there would be fewer problems on site during the construction stage. DfMA embeds the use of BIM and maximizes the prefabrication of the standard building elements to eliminate the on-site activities and boost the on-site productivity. One of them or a hybrid of them may be appropriately selected as a full BIM-based process in the project considering the project specific factors such as the project characteristics and resources priority.

Following this, the logical approach in enhancing the productivity performance would be to strive for the prevention of any possible occurrence of wastes. The role of project management, which is represented through cutting down the non-value adding activities to reduce the wastes, should be identified. Whereas it is desirable to fully prevent the potential wastes from occurring, it is impossible to completely reduce their occurrence by the process change once in one project. This is because not all the activities identified are non-value adding; some may be not significantly non-value adding and remain necessary. Hence a two-pronged approach needs to be adopted wherein (step 3):

| (1) | The significant non-value adding activities such as not involving the general contractor during the design stage are cut through the early involvement of the contractor (Low, Gao and Lin, 2015), and; |

| (2) | The occurrence of the possible wastes due to insignificant non-value adding activities is properly predicted so that appropriate plans can be tailored. |

Step 4 is to transform the current practices into the selected full BIM-based process (see Table 1) in this project. Although the BIM e-submissions have been enforced by the Singapore government, the project-wide BIM collaboration between the design phases and the construction phase is not enough (Lam, 2014). Thus, process changes are imperative in the local construction industry. To transform the current process to adopt BIM more fully, the hindrances to change in terms of People, Process, and Technology needs to be overcome. Lee et al. (2005) stressed that the most problematic barriers in the uptake of new technologies such as BIM are those related to human. This is due to the unpredictability and the multiple effects of the behaviors of the project participants and individuals. Besides, attitude plays an important role in whether the changes proceed smoothly or not. The prerequisite for any new Technology to work is to ensure the synchronization of the Technology and Process as well as the readiness of the Technology and People. But most importantly, the willingness of People to change is required to ensure that the Process can be organized into required applications (Teo, 2008). Hence the most significant problem that the team is likely to face in adopting BIM is people management (Lee et al., 2005). Thus, the hindrances such as psychological afraid of the unknown (Khosrowshahi and Arayici, 2012), lack of BIM experts, top management deciding to mainly use CAD from project to project after training employees on BIM, and concern about initial productivity loss (Eastman et al., 2011) should be overcome.

To meet this need, it is critical to remove the resistance of People to change by getting them to understand the potential value and the benefits of full BIM adoption over the current drafting practices (Khosrowshahi and Arayici, 2012). The most important driver for the BIM systems and their full adoption is to provide information of good quality to People. The improved information quality, building products, visualization tools, cost estimates, and analyses lead to better decision-making in the design stage and fewer wastes during construction. Together with the value of the digital models for operations and maintenance, a snowball effect is likely (Eastman et al., 2011). Other drivers for change such as government requirement and support like subsidizing the cost of BIM software and consultancy, training employees on BIM, top management deciding to use BIM after training, pursuing long-term competitive advantage from BIM to win bids in the future market (Arayici et al., 2011; BCA, 2016) can also be implemented. It should be clarified that these hindrances to and drivers for change towards the full BIM-based processes form the Phase II of the larger study, which is not presented in detail in this paper due to the word limit.

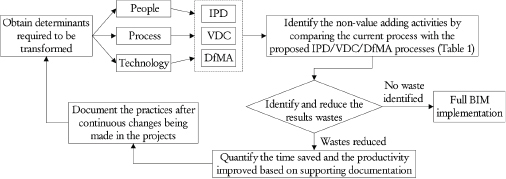

In steps 5 and 6, the wastes caused by the established non-value adding activities in the current process in Singapore are identified and estimated (see Table 2). The identification and reduction of the wastes can be achieved using a waste assessment model (see Figure 4). The occurrence of the wastes is due to a multitude of non-value adding activities established in the steps 2 and 3. After the wastes being identified and assessed, a new process change may be required for further cutting the non-value adding activities until the full BIM implementation is reached.

Figure 4 Flow diagram for waste assessment model

After various resulting wastes are reduced using the waste assessment model, the amount of the derived time savings can be quantified (step 6), according to the documentation of the workers’ time having been spent on dealing with the wastes occurred in this project. For instance, due to poorly coordinated and unclear building plans being used on site in the current practices, tremendous RFIs are raised from the contractors. Such RFIs mean increased field conflicts which cause the workers’ idle time waiting for the consultants’ responses and potential reworks where necessary, resulting in decreased productivity. However, with full BIM use, all the building systems can be fully defined, engineered, and coordinated, greatly reducing the RFIs, idle time, reworks, and so on, eventually increasing the productivity performance (Chelson, 2010).

Validation

The proposed framework was validated using data from a large ongoing residential building project with a GFA of more than 100,000 m2 in Singapore. The data were collected through participant observations and analysis of past documents. The authors participated in the weekly project meetings in the construction site office over two months to observe how the project team collaborated in the BIM work processes; notes were taken promptly and supplemented by using a recorder. Documents such as minutes of meetings and milestone reports were collected from the project manager and were analyzed.

The VDC-ish approach was implemented in this project, with the general contractor as the leading party to coordinate and compile BIM models and the construction BIM execution plan in the construction stage. The large general construction firm had delivered or had been working on many building projects in which the typical BIM uses and processes could be represented by the typical current process described in Table 1 and very often resulted in many non-value adding activities and tremendous wastes such as design changes and reworks. Because of the distinctive differences between the typical process and the VDC process, this project team needed to change the typical way of working. The critical hindrances encountered included the following aspects: (1) adaptability. All the key stakeholders had to change their preferential working habits and lacked training on the new way of working; (2) trade contractors’ capabilities. They preferred to use the 2D drawings for submission and construction, and lacked BIM skillsets; and (3) smooth communication of information. It was difficult to get the major stakeholders to collectively communicate, review, and coordinate the digital models. Nevertheless, to obtain the benefits of BIM, the project team overcame the hindrances by: (1) aligning all the key stakeholders from the beginning and providing project-wide trainings; (2) spearheading BIM model development for all the key trade contractors; (3) involving all the key stakeholders in project meetings to contribute knowledge.

With these strategies, the project team had managed the design well in the construction phase through the following main changes in BIM work practices: (1) sharing design models between the designers, the general contractor, and the key trade contractors. Specifically, after obtaining the regulatory approval, the architect handed over its model to the general contractor for further design development and coordination in the preconstruction stage. The general contractor used the architectural design model as a reference to integrate it with the structural model, and created a high-level construction model which considered the BIM uses of the downstream subcontractors; (2) requiring the trade contractors to use BIM. The subcontractors created their models based on the construction model; and (3) driving collaboration and coordination. The high-level construction model was then virtually displayed, communicated, reviewed, and revised collectively by all the key stakeholders, including precast contractors, in weekly technical meetings in the construction site office, greatly reducing design and construction uncertainties. All the models were approved by the owner and specific designers and combined to guide construction activities (including off-site production) 3 levels ahead versus the actual site progress. During the construction stage, a central data platform was used to help the team members store, view, comment, and monitor the latest composite construction model.

Such process transformation efforts resulted in enhanced productivity performance by the time of this paper. As examples, the productivity improvements for the shop drawing preparation process and RFIs were reported in this paper. The total time spent on preparing the structural and architectural shop drawings was projected from the following activities: (1) coordinating the structural, architectural, and MEP design provisions; (2) preparing the shop drawings; (3) virtually reviewing and revising the designs and drawings; and (4) approving the drawings. Meanwhile, by driving the project-wide collaboration and coordination in the weekly technical meetings, all interfacing issues were virtually resolved, thus substantially reducing the number of the RFIs. Consequently, about 60% of the RFIs raised were related to material or specification clarifications. Compared with its similar residential project of the general construction firm, the estimated time spent for preparing the structural and architectural shop drawings in this project were 836 manhours and 1408 manhours, saved by 40% and 42%, respectively. The numbers of the RFIs in the architecture, structure, and MEP disciplines were 126, 63, and 15, respectively, substantially reduced by 70% in total. The results were in line with Nath et al. (2015) which found that using BIM to re-engineer the precast shop drawing generation process in building projects in Singapore would result in a substantial time saving of 380 manhours of producing the shop drawings, leading to an overall productivity improvement of about 36% for processing time and 38% for total time. Hence, it could be concluded that even the contractual structure and the BIM work activities in the design stage of this residential project remained the same with those of the typical current process adopted in the Singapore construction industry, the project-wide BIM collaboration in the construction stage could also significantly reduce the non-value adding activities and the wastes, enhancing the productivity performance. This finding indicated short-term wins for the project team and represented a benchmark for adopting an appropriate BIM-based process to identify and reduce the process wastes for the productivity enhancement in the Singapore construction industry.

In addition, this framework was also supported by previous studies. For example, Cohen (2010) reported that an interior tenant improvement project was completed using the IPD approach within 8.5 months, an impossible schedule with the typical traditional delivery method used by the owner. Critical changes in People and Process were made. The owner was actively participated. The contractors and suppliers were involved during the design stage to share their expertise; for instance, their virtual construction manager worked together with the architects two days a week. Meanwhile, building officials also participated from early design to ensure that the permitting would not impede the schedule, saving more than one week in the planning reviews. Thus, the documents generated from the composite design model created by the whole team could be used for permitting, analysis, bidding, fabrication, and so on. The contractors could procure time- and cost-variable materials and services earlier. After the detailed design phase, the composite model was moved from the architects to the contractors, instead of being re-built by the contractors in the early construction stage which was non-value adding. During construction, the architects moved to the construction site. This close collaboration with the contractors made many non-value adding activities unnecessary and freed the architects to spend much less time reviewing the RFIs and submittals from the contractors. Consequently, there were 125 RFIs in total on the final cost of $13.34 million, 39.61% fewer than the average 155 RFIs per $10 million recommended by Chelson (2010). The results suggested that compared with the typical current process, following an IPD process and monitoring the project process with a predetermined BIM implementation plan would largely avoid the occurrence of the typical non-value adding activities and potential wastes in the project.

Conclusion

Productivity performance is one of the major problems faced by the construction industry. The Singapore government has expressed concerns and taken relevant measures in recent years to get the industry professionals and owners to understand the potential effects of the full BIM adoption on the productivity performance. To achieve this, this paper developed a project management framework for enhancing the productivity in the construction industry. The key activities related to BIM in the current, IPD, VDC, and DfMA processes, and the resulting wastes seriously affecting productivity were identified and validated by the e-mail exchanges or interviews with 16 BIM experts in Singapore. In addition, both the hindrances to and drivers for changes were interpreted in terms of People, Process, and Technology. Furthermore, the performance of the proposed framework was validated by the case study in an ongoing residential project in Singapore and supported by previous studies as well.

The proposed project management framework expands the process re-engineering of the precast shop drawings production in Singapore (Nath et al., 2015) to the project lifecycle perspective. It is likely that this framework would help remove the non-value adding activities and wastes in the design, construction, and facility management processes and led to a more efficient project delivery. The enhanced productivity performance derived from implementing the project management framework in the residential project indicated that the project-wide collaboration and coordination could be somewhat achieved under the current contractual relationships. Nevertheless, the collaboration and coordination in the earlier stages of the project were not yet achieved, and therefore a collaborative contractual structure that governs the close project-wide collaboration and disciplinary coordination from the beginning throughout project completion remains urgently needed in the Singapore construction industry. Besides the owner’s awareness of and insights into the value that full BIM implementation can add to the project, the incentives like additional GFA may motivate the owner to adopt new contractual solution to reduce the reluctance of the designers and the risk of the downstream parties being involved in an earlier stage. In addition, because in most projects in Singapore the designers tend to lack time and fees to allocate sufficient resources to adopt BIM, the owner may need to require the design team to consider the downstream uses when creating their design models, with more financial incentives.

This paper adds to knowledge on BIM implementation and productivity. Firstly, this paper presents and interprets four typical BIM-based project delivery processes, providing academics and practitioners with valuable information in different research and project contexts. Secondly, it widens the understanding of the non-value adding activities and their influence on the productivity. By knowing the non-value adding activities in building projects, project teams can tailor appropriate plans to deal with various potential resulting wastes according to their project goals, project characteristics, and capabilities of the team members. Thirdly, the proposed framework provides a new technique for measuring the productivity improvement of building projects in Singapore. Time savings are derived from the identification of the non-value adding activities and quantified by the reduction of the consequent wastes. The significant non-value adding activities and disruptive wastes will help the construction industry to rethink its current processes of delivering projects, and ensure that all the practitioners are clearly aware of the opportunities, roles, and responsibilities associated with incorporating BIM into the current project delivery workflow (Anumba et al., 2010). The government can influence the industry’s progress towards full BIM adoption by driving for better project-wide rather than firm-based BIM collaboration and integration throughout the construction value chain. For example, incentive mechanisms are expected to be established for the owner to specify the BIM use in the project delivery, and objective performance milestones need to be launched for the designers and contractors. The project teams should also consider the project context, such as the project goals, the key stakeholders’ goals, and BIM capabilities as well as collaboration skills, and the desired risk allocations to tailor appropriate plans to implement BIM in their building projects (Barley, 1986; Anumba et al., 2010). The Singapore construction industry may explore the IPD, VDC, and DfMA approaches in some projects to make them more integrated in terms of solving issues and processes before the construction phase kicks in. Ultimately, the proposed full BIM-based processes can be applied to improve the productivity of building projects. Thus, with this framework, the construction industry can have an in-depth understanding of how to transform its project delivery process to be more productive.

Although this framework is proposed for the building projects in Singapore in response to the mandatory BIM e-submissions policy and the encouragement for project-wide BIM collaboration. Overseas practitioners may also use the framework. Firstly, like the public sector taking the lead to adopt BIM in Singapore for enhanced productivity, the BIM adoption in publicly funded construction and building projects in the global construction industry is also commonly encouraged, specified, or mandated (Smith, 2014). Secondly, the overseas practitioners can follow the method used in this paper to prepare their customized lists of key practices related to BIM and identify the non-value adding activities in their projects to be reduced according to their specific project characteristics and political contexts.

Nevertheless, the proposed framework has limitations. Firstly, some wastes such as RFIs and workers’ waiting time may be interrelated. Hence it is not possible to achieve complete accuracy when estimating the time savings. Secondly, this paper only presented the results of the time savings for the work process of preparing the coordinated structural and architectural shop drawings as well as the reduced number of RFIs by the time of this paper. The reasons were that the time saving statistics were not fully documented as the residential project was not yet completed, and that the project team tended to be wary of providing all the statistics of the enhanced productivity performance. Thus, it was considered reasonable that this paper only reported the figures of the shop drawing preparation processes and the RFIs as examples to illustrate the enhanced productivity performance resulted from the BIM-based process changes. Thirdly, this framework intends to obtain productivity gains through quantifying the time savings after the process transformation from the partial BIM process to an appropriated full BIM-based process, without considering cost implications of the process changes. Future work is needed to investigate both time savings and cost performance, because owners and construction firms, especially the small and medium-sized enterprises and foreign firms based in Singapore, may concern about the first costs in take-up of BIM technology or processes (Kunz and Fischer, 2012).

DECLARATION OF CONFLICTING INTEREST The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article. FUNDING The author(s) received no financial support for the research, authorship, and/or publication of this article.

References

Abdel-Razek, R.H., Abd-Elshakour, H. and Abdel-Hamid, M., 2007. Labor productivity: benchmarking and variability in Egyptian projects. International Journal of Project Management, 25(2), pp. 189-97. https://doi.org/10.1016/j.ijproman.2006.06.001

AIA and AIACC, 2007. Integrated project delivery: A guide. California: American Institute of Architects.

AIACC, 2014. Integrated project delivery: an updated working definition. California: American Institute of Architects, California Council.

Alarcon, L., 1997. Lean construction. Rotterdam: A.A. Balkema. https://doi.org/10.4324/9780203345825

Al-Sudairi, A.A., 2007. Evaluating the effect of construction process characteristics to the applicability of lean principles. Construction Innovation: Information, Process, Management, 7(1), pp. 99-121.

Alter, S., 2015. Beneficial noncompliance and detrimental compliance: expected paths to unintended consequences. In: Proceedings of the 21st Americas Conference on Information Systems (AMCIS 2015). Fajardo, Puerto Rico.

Alwi, S., Hampson, K. and Mohamed, S., 2002. Non value-adding activities: a comparative study of Indonesian and Australian construction projects. In: Proceedings of the 10th Annual Conference of the International Group for Lean Construction. Gramado, Brazil, pp. 627-38.

Anumba, C., Dubler, C., Goodman, S., Kasprzak, C., Kreider, R., Messner, J., Saluja, C. and Zikic, N., 2010. BIM project execution planning guide – version 2.0. Computer Integrated Construction Research Program, Pennsylvania State University.

Arayici, Y., Coates, P., Koskela, L., Kagioglou, M., Usher, C. and O’Reilly, K., 2011. BIM adoption and implementation for architectural practices. Structural Survey, 29(1), pp. 7-25. https://doi.org/10.1108/02630801111118377

Autodesk, 2008. Improving building industry results through integrated project delivery and building information modelling. US: Autodesk, Inc.

Autodesk, 2012 A framework for implementing a BIM business transformation. US: Autodesk, Inc.

Azhar, N., Kang, Y. and Ahmad, I.U., 2014. Factors influencing integrated project delivery in publicly owned construction projects: an information modelling perspective. Procedia Engineering, 77, pp. 213-21. https://doi.org/10.1016/j.proeng.2014.07.019

Barley, S.R., 1986. Technology as an occasion for structuring: evidence from observations of CT scanners and the social order of radiology departments. Administrative Science Quarterly, 31, pp. 78-108. https://doi.org/10.2307/2392767

BCA. (2011a) Construction productivity roadmap. Singapore: Building & Construction Authority.

BCA. (2011b) Overview on construction productivity roadmap. Singapore: Building & Construction Authority.

BCA. (2013) Singapore BIM guide version 2. Singapore: Building & Construction Authority.

BCA. (2015) The second construction productivity roadmap. Build Smart, June 2015.

BCA. (2016) Reaching new milestones with design for manufacturing and assembly. Build smart. Singapore: Building & Construction Authority.

Blismas, N. and Wakefield, R., 2009. Drivers, constraints and the future of offsite manufacture in Australia. Construction Innovation, 9(1), pp. 72-83. https://doi.org/10.1108/14714170910931552

Chelson, D.E., 2010. The effects of building information modelling on construction site productivity. Ph.D. University of Maryland, College Park.

Chua, D.K. and Yeoh, J.K., 2015. Understanding the science of virtual design and construction: what it takes to go beyond building information modelling. In: Proceedings of the 2015 ASCE International Workshop on Computing in Civil Engineering. Austin, Texas, USA, pp. 692-99. https://doi.org/10.1061/9780784479247.086

Cohen, J., 2010. Integrated project delivery: case studies. California: American Institute of Architects, California Council.

Eastman, C., Teicholz, P., Sacks, R. and Liston, K., 2011. BIM handbook: a guide to building information modelling for owners, managers, designers, engineers and contractors. 2nd ed. New Jersey: John Wiley & Sons.

Ekanayake, L.L. and Ofori, G., 2004. Building waste assessment score: design-based tool. Building and Environment, 39(7), pp. 851-61. https://doi.org/10.1016/j.buildenv.2004.01.007

Enegbuma, W.I., Aliagha, U.G. and Ali, K.N., 2014. Measurement of theoretical relationships in Building Information Modelling adoption in Malaysia. In: Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining. Sydney, Australia, pp. 1000-08.

ESC, 2010. Report of the Economic Strategies Committee. Singapore: Economic Strategies Committee.

Fischer, M., Reed, D., Khanzode, A. and Ashcraft, H., 2014. A simple framework for integrated project delivery. In: Proceedings of the 22nd Annual Conference of the International Group for Lean Construction. Oslo, Norway, pp. 1319-30.

Formoso, C.T., Isatto, E.L. and Hirota, E.H., 1999. Method for waste control in the building industry. In: Proceedings of the 7th Annual Conference of the International Group for Lean Construction. University of California, Berkeley, CA, USA, pp. 325-34.

Gao, J. and Fischer, M., 2006. Case studies on the implementation and impacts of virtual design and construction (VDC) in Finland. Center for Integrated Facility Engineering, Stanford University.

Gibb, A. and Isack, F., 2003. Re-engineering through pre-assembly: client expectations and drivers. Building Research & Information, 31(2), pp. 146-60. https://doi.org/10.1080/09613210302000

Kent, D.C. and Becerik-Gerber, B., 2010. Understanding construction industry experience and attitudes toward integrated project delivery. Journal of Construction Engineering and Management, 136(8), pp. 815-25. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000188

Khosrowshahi, F. and Arayici, Y., 2012. Roadmap for implementation of BIM in the UK construction industry. Engineering, Construction and Architectural Management, 19(6), pp. 610-35. https://doi.org/10.1108/09699981211277531

Kunz, J. and Fischer, M., 2012. Virtual design and construction: themes, case studies and implementation suggestions. Center for Integrated Facility Engineering, Stanford University.

Lam, S.W., 2014. The Singapore BIM roadmap. Singapore: Building & Construction Authority. Available at: http://bimsg.org/wp-content/uploads/2014/10/BIM-SYMPOSIUM_MR-LAM-SIEW-WAH_Oct-13-v6.pdf [Accessed 7 December 2016].

Lee, A. and Sexton, M.G., 2007. nD modelling: industry uptake considerations. Construction Innovation, 7(3), pp. 288-302. https://doi.org/10.1108/14714170710754768

Lee, A., Wu, S., Marshall-Ponting, A.J., Aouad, G., Cooper, R., Tah, J.H.M., Abbott, C. and Barrett, P.S., 2005. nD modelling roadmap – a vision for nD-enabled construction, University of Salford.

Lee, S.H., Diekmann, J.E., Songer, A.D. and Brown, H., 1999. Identifying waste: applications of construction process analysis. In: Proceedings of the 7th Annual Conference of the International Group for Lean Construction. Berkeley, CA, USA, 26-28 July 1999, pp. 63-72.

Low, S.P., Gao, S. and Lin, J.L., 2015. Converging early contractor involvement (ECI) and lean construction practices for productivity enhancement: Some preliminary findings from Singapore. International Journal of Productivity and Performance Management, 64(6), pp. 831-52. https://doi.org/10.1108/IJPPM-02-2014-0018

Markus, M.L. and Robey, D., 1988. Information technology and organizational change: causal structure in theory and research. Management Science, 34(5), pp. 583-98. https://doi.org/10.1287/mnsc.34.5.583

McFarlane, A. and Stehle, J., 2014. DfMA: engineering the future. In: Proceedings of Council on Tall Buildings and Urban Habitat (CTBUH) 2014 Shanghai Conference. Shanghai, China, pp. 508-16.

McGraw Hill Construction, 2014. The business value of BIM for owners. McGraw Hill Construction: SmartMarket Report.

Nath, T., Attarzadeh, M., Tiong, R.L., Chidambaram, C. and Yu, Z., 2015. Productivity improvement of precast shop drawings generation through BIM-based process re-engineering. Automation in Construction, 54, pp. 54-68. https://doi.org/10.1016/j.autcon.2015.03.014

Nikakhtar, A., Hosseini, A.A., Wong, K.Y. and Zavichi, A., 2015. Application of lean construction principles to reduce construction process waste using computer simulation: a case study. International Journal of Services and Operations Management, 20(4), pp. 461-80. https://doi.org/10.1504/IJSOM.2015.068528

Ohno, T., 1988. Toyota production system: beyond large-scale production. Portland: Productivity Press.

Porwal, A. and Hewage, K.N., 2013. Building information modelling (BIM) partnering framework for public construction projects. Automation in Construction, 31, pp. 204-14. https://doi.org/10.1016/j.autcon.2012.12.004

Ranasinghe, U., Ruwanpura, J. and Liu, X., 2011. Streamlining the construction productivity improvement process with the proposed role of a construction productivity improvement officer. Journal of Construction Engineering and Management, 138(6), pp. 697-706. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000469

Ross, K., Cartwright, P. and Novakovic, O., 2006. A guide to modern methods of construction. Bucks: IHS BRE Press, NHBC Foundation.

SDOS, 2016. Yearbook of statistics Singapore 2016. Singapore: Department of Statistics.

Senaratne, S. and Wijesiri, D., 2008. Lean construction as a strategic option: testing its suitability and acceptability in Sri Lanka. Lean Construction Journal, 4(1), pp. 34-48.

Senge, P.M., 1990. The fifth discipline: the art and practice of the learning organization. New York: Currency Doubleday.

Smith, P., 2014. BIM implementation–global strategies. Procedia Engineering, 85, pp. 482-92.https://doi.org/10.1016/j.proeng.2014.10.575

Solihin, W. and Eastman, C., 2015. Classification of rules for automated BIM rule checking development. Automation in Construction, 53, pp. 69-82. https://doi.org/10.1016/j.autcon.2015.03.003

Teo, A.L., 2008. Online survey: factors deterring the development of automated quantity taking-off system. In: Proceedings of Joint 2008 CIB WO65/W055 Symposium. Dubai, United Arab Emirates.

Teo, A.L. and Heng, P.S.N. 2007. Deployment framework to promote the adoption of automated quantities taking-off system. In: Proceedings of the CRIOCM2007 International Research Symposium on Advancement of Construction Management and Real Estate. Sydney, Australia, 8-13 August 2007, pp. 928-43.

Teo, A.L.E., Ofori, G., Tjandra, I.K. and Kim, H., 2014. The potential of BIM for safety and productivity. In: Proceedings of CIB W099 International Conference Achieving Sustainable Construction Health and Safety. Lund, Sweden, pp. 618-27.

Teo, E.A.L., Chan, S.L. and Tan, P.H., 2007. Empirical investigation into factors affecting exporting construction services in SMEs in Singapore. Journal of Construction Engineering and Management, 133(8), 582-91. https://doi.org/10.1061/(ASCE)0733-9364(2007)133:8(582)

Wong, P.F., Salleh, H. and Rahim, F.A.M., 2014. Capability of Building Information Modelling Application in Quantity Surveying Practice. Journal of Surveying, Construction and Property, 5(1), pp. 1-13.

Wu, P. and Feng, Y., 2014. Identification of non-value adding activities in precast concrete production to achieve low-carbon production. Architectural Science Review, 57(2), pp. 105-13. https://doi.org/10.1080/00038628.2013.829023

Wu, P. and Low, S.P., 2011. Lean production, value chain and sustainability in precast concrete factory - a case study in Singapore. Lean Construction Journal, 2011, pp. 19-36.

Wu, P. and Low, S.P., 2012. Lean management and low carbon emissions in precast concrete factories in Singapore. Journal of Architectural Engineering, 18(2), pp. 176-86. https://doi.org/10.1061/(ASCE)AE.1943-5568.0000053

Wu, P., Low, S.P. and Jin, X., 2013. Identification of non-value adding (NVA) activities in precast concrete installation sites to achieve low-carbon installation. Resources, Conservation and Recycling, 81, pp. 60-70. Zhao, X., Hwang, B.G. and Low, S.P., 2015. An enterprise risk management knowledge-based decision support system for construction firms. Engineering, Construction and Architectural Management, 23(3), pp. 369-84.