VIEWPOINT

Insights into Architects’ Future Roles in Off-Site Construction

Jianing Luo1, Hong Zhang1, Willy Sher2

1Southeast University, China

2The University of Newcastle, Australia

Construction Economics and Building, Vol. 17, No. 1, March 2017

© 2017 by the author(s). This is an Open Access article distributed under the terms of the Creative Commons Attribution 4.0 International (CC BY 4.0) License (https://creativecommons.org/licenses/by/4.0/), allowing third parties to copy and redistribute the material in any medium or format and to remix, transform, and build upon the material for any purpose, even commercially, provided the original work is properly cited and states its license.

Citation: Luo, J., Zhang, H. & Sher, W. 2017. Insights into Architects’ Future Roles in Off-Site Construction. Viewpoint, Construction Economics and Building, 17:1 107-120. http://dx.doi.org/10.5130/AJCEB.v17i1.5252

ISSN 1836-0394 | Published by UTS ePRESS | ajceb.epress.lib.uts.edu.au

Corresponding author: Jianing Luo, Southeast University, Sipailou, Xuanwu Qu, Nanjing Shi, Jiangsu Sheng, 210018, China. jianing.luo@seu.edu.cn

DOI: http://dx.doi.org/10.5130/AJCEB.v17i1.5252

Article History: Received 04/01/2017; Revised 14/02/2017; Accepted 04/03/2017; Published 31/03/2017

Abstract

Today’s construction industry is overflowing with new ideas about its future. Off-Site Manufacture and Construction (OSCM) is at the heart of the modern construction industry. Much has been written about the state and context of OSCM in different countries regarding its perceived benefits and barriers to implementation. Off-site production (OSP) plays an important role in improving fragmented construction processes. Although most OSP research targets the attitudes and practices of OSP adoption, there is limited understanding of the philosophical issues underpinning OSP-related architecture. The roles of the architects’ personal philosophies are neglected and this hampers their implementation of OSM (which has had a largely technical focus). This paper explores the traditional thinking patterns of architects in China and predicts possible future roles for them. It then conceptualizes an “architectural work” mode and a “building product” mode of design and construction and identifies the shortcomings of architects in an OSCM environment. The arguments made are based on practitioners’ perceptions and the first author’s practical experiences of leading several real-life projects in recent years. The findings reveal the implications and significance of the transformation from an “architectural work” mode to a “building product” mode. We foresee a study approach that focuses on the order and rules for OSCM, resulting in architects’ existing mindsets being changed to thinking patterns and design methodologies better suited to OSM.

Keywords

Off-site manufacture and construction, future roles, “architectural work” mode, “building product” mode, order and rules

Introduction

Off-Site Manufacture and Construction (OSCM) has long been recognised, in China and internationally, for the potential and numerous benefits it provides. The increasing complexity of modern buildings, the increasing number of construction functions they perform, in addition to the community’s increased awareness of sustainable development has accentuated the focus on off-site construction and associated techniques. OSCM is at the heart of the modern construction industry and translates the needs of customers into the components from which tomorrow’s buildings will be assembled. Many academics and practitioners are struggling to identify where and how they will fit into a transformed construction industry.

In facing these challenges, an ever-increasing number of investigations into new materials, methods of fabrication, assembly methods and related supporting technologies have been developed over the years. Examples include the research and development of building industrialisation in China (Ji, 2011); off-site manufacture in Australia (Blismas and Wakefield, 2009); prefabricated residential building in Hong Kong (Jaillon and Poon, 2009); prefabrication, preassembly, modularization, and off-site fabrication in the United States (Song et al. 2005); the development of prefabricated house building in Japan (Barlow and Ozaki, 2005); off-site manufacturing housing in Germany (Venables and Courtney, 2004); off-site modern methods of construction in U.K (Pan, Gibb and Dainty, 2007) and the research project ‘Adding value to construction projects through standardisation and pre-assembly’ funded by CIRIA (Construction Industry Research and Information Association) in UK (Gibb, 2001). These investigations analysed and summarized the state and context of OSCM in different countries. For instance, Blismas and Wakefield (2009) identified the benefits, drivers, and constraints in Australia. These benefits and drivers include reductions in time, defects, health and safety risks, environmental impact, and whole-life costs and increases in predictability, productivity, performance, and profitability. The constraints include unreliable, unquantifiable, unpredictable, fragmented, unique, and repetitive processes and program, high initial and set-up costs, incompatible regulations, poor skills and knowledge, traditional industry and market culture, and incompatible supply chain and procurement. Several research projects have been conducted to identify the factors that drove or constrained the uptake of OSP (e.g., Blismas et al., 2005; Bottom et al., 1994; Sparkman et al., 1999, Gibb, 2000; Fox, Marsh and Cockerham, 2001; Gibb and Isack, 2003; Housing Forum, 2002; Neale, Price and Sher, 1993).

With respect to discontinuous construction processes and programs, Blismas and Wakefield (2009) found that the disciplines and processes involved in designing and constructing buildings need to be streamlined. Existing design processes and methodologies are based on traditional approaches and are not suited to OSM. Improved design tools, better engineering solutions and simpler controls and specifications need to be developed. Nawi, Lee and Nor, (2011) concluded that traditional approaches lead to barriers between designers, contractors and manufacturers and may result in errors and sloppy work (Thanoon et al., 2003). This necessitates the redesign of plans and working drawings resulting in additional costs and time (Hamid et. al., 2008). This is known as an “over the wall” approach because design professionals pass unresolved problems to their colleagues (Evbuomwan and Anumba, 1998). This practice restricts manufacturers’ and contractors’ involvement to after the design stage, creating problems (including delays and late deliveries) for the rest of the supply chain and constructability related issues (Nawi, Lee and Nor, 2011). In addition, this approach is arguably one of the main hindrances to the effective integration of design and construction in OSCM projects (Hamid et. al, 2008; Nawi, Lee and Nor, 2011).

Background: the purpose of understanding architects’ philosophies

The design processes commonly used are based on traditional approaches. These are unsuited to OSM, and pose a substantial barrier to the adoption of this construction method (Blismas and Wakefield, 2009). Facing these challenges, an increasing number of architects have learned from the manufacturing industry and see buildings as manufactured products. Previous research has identified off-site production (OSP) as a means of improving construction processes (Egan, 1998). It has long been recognized in both the manufacturing industry (Peck, 1973) and the construction industry (Emerson, 1962) that productivity and quality can be improved by integrating production-related best practice into designs (Fox, Marsh and Cockerham, 2001). Applying methodologies and evaluation metrics from the manufacturing industry to the construction industry should be advantageous (e.g., Blismas et al., 2005; Blismas and Wakefield, 2009, Blismas et al., 2005; Dean and Susman, 1989, Emerson, 1962; Fox, Marsh and Cockerham, 2001; Fox, Marsh and Cockerham, 2002; Gibb, 2001; Ji, 2011; Peck, 1973).

Much research has been conducted to promote the uptake of OSP in construction from different aspects. In the early 2000s, Fox et al. (2001) found that design engineers in the manufacturing industry had proven methodologies to help them and these led to radical improvements. However, in the construction industry, building designers lacked equivalent methodologies, and the integration of production best practice into designs continues to rely on the varying experience of individuals. Blismas et al. (2005) identified four broad constraint themes to the use of OSP in construction in terms of process, value, supply chain and knowledge. He constructed a model illustrating the relationships between these four themes. Knowledge was identified as the essential factor related to other constraints. Blismas went on to identify employing knowledge input to the other three constraint themes as the key strategies to mitigate these constraints. He concluded that mitigating the constraints obstructing the use of OSP on construction projects should be addressed at the macro level by increasing designers’ knowledge. Pan, Gibb and Dainty (2012) explored strategies for integrating the use of OSP technologies in house building at the organizational level. They identified the following critical constraints to the use of OSP in construction: fragmented processes in the design stage, unsuitable design methodologies, as well as practitioners with little knowledge and experience of OSP. These hinder the implementation of OSP in OSM, as well as the streamlined processes and programs of OSCM.

In facing these challenges and to explore design methodologies suited to OSM, it is necessary to focus on the key practitioners in the design process - architects. Since at least the early 1960s, it has been recognized that building design has a significant impact on construction productivity and quality (HMSO, 1962). Architects are still the critical specifiers in today’s off-site construction industry. Indeed, architects continue to be held responsible for productivity and quality problems because of their lack of understanding, or even appreciation, of building construction (Fox, Marsh and Cockerham, 2002; Harding, 1999; Soubry, 2001). Although most research on OSP targets the attitudes and practices surrounding the uptake of OSP, there is limited understanding of the philosophical issues underpinning OSP-related architecture. The role of architects’ personal philosophies in implementing OSM have largely been neglected. Their philosophies are frequently based on existing traditional design processes and methodologies, which are not suited to OSM. This inevitably leads to fractured construction processes and programs. We argue that such traditional and introspective mindsets need to be changed. Little reference is made about introspection on the part of architects in research papers. This aspect is worthy of investigation.

Research aim, objectives and scope

The aim of this research was to develop an alternative study approach which could be used to explore design methodologies suited to OSM. It is based on the foresight and analysis of architects’ future roles. Its objectives were: first, to explore the traditional thinking patterns and philosophies of architects in China; second, to identify the shortcomings of architects in an OSCM environment; third, to offer possible future scenarios in which architects’ philosophies evolve to encompass alternative design methodologies suited to OSM; and finally, to propose an alternative study approach. The research also focuses on conceptualizing the traditional thinking patterns and philosophies of architects, as well as the alternative thinking patterns and design methodologies required in the new paradigm. Consequently, an alternative study approach is required. The findings presented here do not assert that this study approach will deliver design methodologies ideally suited to OSM. Instead, this study provides viewpoints as a starting point for further discussion and development.

Method

A phenomenological approach and a case study were adopted for this study. Phenomenological research seeks to understand people’s perceptions, perspectives, and understandings of a particular situation (or phenomenon). It is well documented that insider experience is crucial to understanding a community (Thoresen and Öhlén, 2015). A first-person perspective has been provided via reflections of the first-named author’s personal experiences (Sloan and Bowe, 2014; Van Manen, 1997). Fook (2011) considers critical reflection as a research method. In addition, Yin (2003) contends that the case study approach is especially appropriate for exploratory research, addressing why and how questions. Case study methodologies are widely used in construction engineering and management (Taylor, Dossick and Garvin, 2011).

In this investigation, these approaches were adopted. Several personal communications were collected and analysed to explore the traditional thinking patterns and philosophies of architects in China. A case study was used to reveal the shortcomings of architects in an OSCM environment. In this case the first author was a teaching assistant who systematically observed the whole process. He interviewed and communicated with architects. Several semi-structured face-to face interviews were conducted. The interview questions were derived from the first author’s reflections of his practical, first-hand experiences as a project leader in a real-life project (Luo, Zhang and Sher, 2016). Interviewees involved higher degree students (who were considered as junior architects), academics (as senior architects) and employees in the cooperating construction companies. These data were used to conceptualize “architect centric”, an “architectural work” mode and a “building product mode”. These served to underpin views about the possible future roles of architects and serviced an alternative study approach based on “order and rules” which could be used to explore design methodologies suited to OSM.

Traditional thinking patterns

Traditionally, architects used to be recognized as the first specifiers in the entire construction supply chain. They bridge between clients and implementers, and between coordinators, suppliers, and constructors. Other specifiers acted as “service departments” for architects. These relationships can be simply summarized as: architects were responsible to their clients for drawings; builders were responsible for realizing the drawings, while various engineers were responsible for other necessary components of buildings. As an academic in an architecture school in China concluded: “most architects believe that they are mainly responsible for design. They rarely take responsibility for managing building operations or if they do, they consider it at a relatively shallow level and through the lens of an architect. This is because architects generally believe that builders should oversee site activities.” (Zhang, Pers. Comm., 2014).

“ARCHITECTURAL WORK” MODE

Architects sometimes instinctively stress their concepts and suggestions to their customers. This is understandable on landmark or public buildings that require impressive ideas to represent images of cities or countries. However, most buildings in cities are residential buildings. They are conventional structures that should prioritize their clients’ comfort. The reality is that most residential buildings in China are over-designed by architects. Architects arguably aspire to their work being recognizable, thereby improving their reputation and future prospects.

Consequently, concentrating on design concepts while overlooking the management of building operations leads to “strong error-tolerance”. Architects fix problems after they occur on construction sites. This “Build-and-Fix” model requires architects to demonstrate their talents and abilities. They immerse themselves in solving the various conflicts that occur between their design drawings and what happens on site. These conflicts have become commonplace in the construction industry. Every sector is accustomed to this state of affairs. Architects have arguably become resigned to addressing the shortcomings of their designs in this manner. Although some may argue that this is team cooperation, it is architect-centric.

This phenomenon has been described as an “architectural work” mode by an academic in an architecture school in China. He argued that “architects design buildings to suit customer requests, adopting traditional design methods based on architects’ personal professional skills and talent. This design method derives from the old architectural education system including Ecole des Beaux-Arts. The same customer requests may result in various designs by different architects. Most architects treat their designs as works of art which can be highly recognizable. The buildings are unique and cannot be duplicated.” (Zhang, Pers. Comm., 15 May 2014). He concluded that most architects adopt this approach - it is their creed. They have balanced art and technology, spatiality and buildability, design and construction for hundreds of years - “it is not easy to think out of the box and break the routine. From this perspective of architects’ creed, it is difficult to put customers in front and streamline the entire construction supply chain” he said.

CASE STUDIES

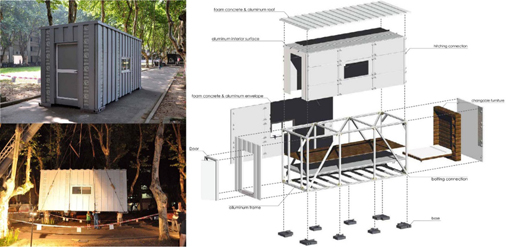

A case study was used to understand participants’ perceptions and to reveal the shortcomings of architects in the “architectural work” mode when they face the challenges of OSCM. The traditional preferences that impede architects from adopting new ideas and perspectives were identified. The interview questions asked were derived from the first author’s reflections of his practical, first-hand experiences as a project leader in a real-life project (Luo, Zhang and Sher, 2016). “Emergency Construction” was a real-life building adopting OSCM (Figure 1). It was also a final learning outcome of a construction teaching practice in an architecture school in China. The author was a teaching assistant who could systematically observe the whole process and to interview and communicate with architects.

Figure 1 Emergency construction

“Emergency Construction” was a small building which was designed and constructed to provide an effective and timely solution after a disaster. Ease of prefabrication, transportation, assembly, use, demolition and reuse were thus of paramount importance. OSCM was chosen as the best technical approach to achieve these goals. This building was also a construction teaching exercise (for students, academics, and other practitioners) designed to inform all concerned how to translate drawings into buildings. As such, those involved needed to not only develop their design and construction drawings, but also more detailed drawings (including production drawings or “building process drawings”). These needed to be more comprehensive than traditional construction drawings because they needed to support production, prefabrication, assembly, and transportation. The architects involved became aware of the way manufacturing and construction impacted on their designs. In addition, they found it hard to identify the costs involved because they lacked the necessary cost engineering knowledge. In many cases, what was drawn could not be fabricated or assembled. Participants became aware that some issues could not be represented on drawings and were easy to overlook.

Additionally, participants were not aware of the need to incorporate manufacturing tolerances to ensure that components could be accurately assembled. Little attention was paid to these issues but it became most apparent that architects needed to make such allowances to ensure accurate on-site assembly.

After the “Emergency Construction” project was completed, practitioners were interviewed. These involved higher degree students (who may be considered as junior architects), academics (as senior architects) and employees in the cooperating construction companies.

A student attending this construction practice said: “Through this course, I felt the gaps between drawings and real-life buildings. As an architect, the drawings should be treated with strict and caution. I should learn knowledge more than design skills in the future.” (Name Withheld, Pers. Comm., 2011a)

An academic who guided the students commented: “As an academic and architect who had many years’ experience in the industry, sometimes I was still not very confident to predict the issues that may occur in the following process. In this construction practice, I was also learning like students all the time. To some extent, this kind of practical experiences was fresh to me.” (Name Withheld, Pers. Comm., 2011b).

A technical director in the factory who assisted the manufacture and construction of this building said: “Sometimes we cannot use architects’ drawings directly to fabricate and assemble, we need to adjust them to be more suitable to the actual manufacture and construction processes in our factory. There is a long way to go in the collaboration between the designers and implementers particularly in OSCM projects. The architects should be equipped with OSCM specific skills.” (Name Withheld, Pers. Comm., 2011c).

Many architects find it challenging to control their projects in the face of new technologies. In some cases, they become more “technical” than “artistic”. The criteria by which buildings are evaluated are quantifiable and measurable to some extent. Some innovative construction activities are gradually confirming this. For example, the Solar Decathlon Competitions (held from 2002 to 2015 by the U.S. Department of Energy) were collegiate competitions that challenged student teams to design and build full-size, solar-powered houses. Teams needed to present a design appropriate to their target market, which functioned competitively at the competition site. The teams worked not only to develop and build their houses, but also to enhance integration and generation of knowledge on sustainable construction. The winner of the competition was the team that best blended design excellence and smart energy production with innovation, market potential, and energy and water efficiency. All contests were evaluated based on quantifiable and measurable criteria (U.S. Department of Energy, 2015).

These findings align with those of Blismas (2007) and Ji (2011). The skills and knowledge constraints they identified were described as “Lack of skills by professionals in OSM, with subsequent effects on the entire process”, “Lack of skills in manufacturers/ suppliers to enhance OSM efficiency”, “Lack of industry investment in R&D”, “Lack of knowledge repository, portal” (Blismas, 2007). These shortcomings were also evident in the Emergency Construction project.

Reflection and discussion

The traditional thinking pattern inherent in the “architectural work” mode has dominated the industry for several decades. However, in the OSCM sector, architects lack practical experience in manufacturing, construction and have limited cost engineering knowledge. These shortcomings restrict their decision-making abilities. Many architects realize that they are gradually losing control of projects because their knowledge and educational background are limited to traditional design and construction approaches.

Some architects and academics are already aware of the shortcomings and are endeavouring to reinvent themselves to recapture their “leadership position”. They are expanding into other sectors by learning related new knowledge to reinvent themselves as professional and powerful players when they collaborate with others. Some pin their hopes on BIM as a panacea or pursue more influential roles in other construction sectors. Rex Miller’s ‘The Commercial Real Estate Revolution’ (Miller, et al., 2009, p.47) describes how today’s construction firms are grappling with decreasing profit margins and looking at expanding their services to provide greater value to clients and achieve greater control over their fate. To achieve this, they point to “construction firms adding architects, architects expanding into construction services, brokers adding project and facility management services, and still others… creating one-stop-shop capabilities.” They conclude “When the lines blur like this, it is a sure sign of more fundamental shifts taking place.”

“ARCHITECT CENTRIC”

It is time for architects to end their era of “individualistic heroism” and establish authentic cooperative relationships between different sectors in the construction industry. The view expressed by the deputy head of a leading architecture school in China; “Today’s architects are in an awkward position. We are not as free as real artists because we need to be restricted by rationality derived from design skills. We are not as technical as other engineers because the discipline character and educational background make us so. We need to relocate our position and rethink what responsibilities we should really take.” (Gong, Pers. Comm., 2013). This may mean reasserting leadership, or it may be something else.

This view was reinforced by the first-named author’s experience as a postgraduate in an architecture school in China. A civil engineer who worked with the first author complained: “Why should I follow architect’s drawings, especially sometimes even architects themselves have not found the rational reasons why they were drawing so. They can say this is because of building codes or design method, or because of client demand or professional analysis. Mostly, these are their own personal games and cannot make me convinced.” (Zhu, Pers. Comm., 2013). This engineer’s words may be forthright, but they reveal the challenges inherent in the current construction industry practice.

Off-site production (OSP) has been promoted as one of the solutions to the industry’s performance problems. Some architects have started to learn from the manufacturing industry and see buildings as manufactured products.

Even so, customization is inevitable. It is a design activity trapped in the “architectural work” mode. It is acknowledged that buildings are essentially complex customized products and that each project requires a unique pattern of linkages with every sector involved. No matter how they grapple with these challenges, or adopt manufacturing knowledge to design buildings, most architects still adhere to an “architectural work” mode, highlighting their personal talents. This is like the endless cycle shown in Figure 2.

Figure 2 Endless Cycle: reflects the current situation on practices of applying OSP into construction in “architectural work” mode

“BUILDING PRODUCT” MODE

In the broader products-based construction industry, clients are likely to have more products to choose from and more opportunities to select them. Products will be eliminated if the market does not accept them. Corresponding to the “architectural work” mode, a “building product” mode was proposed by the second author of this paper. He defined it in the following terms: “Architects treat their designs as industrial products. The architects incorporate customer requests into feasible and rational implementation from drawings to end products. The buildings will be endowed with attributes of other industrial products and the architects will give priority to better customer experience and smooth implementation in the following project phases instead of highlighting their works of art. Based on this mode, the process will transform from personal design to product development. The buildings can be duplicated in some cases and mass customized fabrication may come true.” (Zhang, Pers. Comm., 2014).

AN ALTERNATIVE THINKING PATTERN AND FUTURE ROLES OF ARCHITECTS

So, what will happen if the “architectural work” mode to a “building products” mode was transferred and morph architects into product engineers? Would significantly increasing the industrial component content of buildings offer more valuable and better services to clients?

Pragmatic architects are likely to prioritize improved customer experience and smooth implementation in future work. Architects’ future roles may be likened to experienced coordinators and interdisciplinary engineers who balance the demands and requirements of clients, designers to implementers such as manufacturers and builders to minimize unpredictable issues. Based on this mode, this process will transform personal design into product development. This transition may be considered as an alternative thinking pattern, converting the “architectural work” mode to a “building product” mode. This is an area worthy of further investigation as it will contribute to the development of alternative design methodologies suited to OSM.

Prospect: an alternative study approach

The challenges outlined above underpin our OSCM research. To explore an alternative design approach suited to OSM in the “building product” mode, the first and the second author propose a new OSCM “order and rules” for off-site construction manufacture and on-site assembly. The current challenge is not how to build or obtain information. It is how to enable cooperative work by allowing every sector to access database information on the same platform. BIM, for example, is a container and tool for managing information, but construction professionals also need to use this appropriately and effectively. If not, all the sectors become confused and the shared information is meaningless.

“ORDER AND RULES”

In the manufacturing industry, design engineers have proven methodologies to help them and these have led to radical improvements. They comprise standard design improvement rules and standard design evaluation metrics (Fox, Marsh and Cockerham, 2001). The term used to describe these is “design for manufacture” (DFM). In the construction industry, architects have no equivalent methodologies (Fox, Marsh and Cockerham, 2001), or are not familiar with equivalent design methods. The integration of production best practice into designs continues to rely on the varying experience of individuals.

The first and the second authors’ hypothesis is that “order and rules” can be defined as standard principles, platforms and databases which will contribute to an information exchange mechanism that promotes effective integration and communication between architects, manufacturers, constructors, inspectors, and end customers. “Order and rules” may provide advanced design processes and equivalent design methodologies suited to OSM in the “building product” mode.

To explore what is “order and rules” for OSM, specifically, “order and rules” aims to identify constituent prefabricated components (PCs) from which prefabricated buildings (PBs) are constructed, as well as the methods, principles, and processes in which they are constructed. Current processes for constructing PBs include sub-processes of design, manufacture, delivery, and construction.

Based on the refined data, standard principles, platforms, and databases could be established as guidelines mainly for (but not limited to) architects, as well as manufacturers and constructors. On the one hand, these guidelines can assist architects to enhance their designs leading to smooth implementation, thereby satisfying their customers. On the other hand, they also assist during project phases such us manufacture, delivery, construction, and maintenance. They should be measurable and help make OSCM cooperative work possible. We argue that this is the missing piece of the OSCM puzzle.

The UK’s Build-offsite Property Assurance Scheme (BOPAS), (BOPAS, 2015) is an example of a set of guidelines in accordance with “order and rules”. This adopts a “chain of custody” concept for construction supply lines. This initiative is at the forefront of negotiations with lead underwriters and financial institutions to deliver to their members the ability to assure customers full construction performance across vendors. The BOPAS database is populated through a series of evaluations and standards and can be accessed by all the stakeholders involved.

ONGOING OSCM CASE STUDIES

A series of investigations of off-site manufacture (OSM) buildings using a case study approach will be conducted to explore this alternative design approach suited to OSM. Essentially, OSM buildings represent the assembly of various prefabricated components (PCs). Building form generation is a combination of methods. All buildings are derived from a combination of design drawings and basic components. If this approach is followed, “Order and rules” can be identified and advanced.

Using the concept of “order and rules”, the internal relationships of OSM buildings could be revealed from design drawings to real-life buildings. Our investigation will seek participation from professionals and individuals in organisations that use accepted concepts of project phases in the design stage, off-site production stage, delivery stage and construction stage of OSM projects. Professionals will be invited to participate in semi-structured face-to-face interviews. Organisations will be invited to provide professional/technical documents and host site/factory visits. The questions, documents and photographs taken will revolve around demonstrating how buildings are generated from components. The research also seeks those who are engaged directly by the end customer or form part of a traditional supply chain. The findings of this study will be published on completion.

Research limitations

This research focuses on the traditional thinking patterns of architects in China and foresees possible future roles. Terms including “architect centric”, “architectural work” mode, “building product mode” and “order and rules” are new concepts, partly summarized and derived from informal personal communications and conceptual ideas not published before. They are based on the authors’ practical and first-hand experiences and offered as a foundation for terminology in this emerging field. We acknowledge that the terms are subjective and potentially controversial but argue that they provide a starting point for further discussion and development. We are not aiming to define thinking patterns and design methodologies for OSM, nor are we seeking to specify the thinking patterns of architects. These will take time to evolve and be tested and verified. However, they provide alternatives and approaches which may suit OSM. More importantly, we trust architects will be encouraged to reflect on their practices and consider other perspectives and provide positive proposals for other sectors of the construction industry.

Conclusion

Our study has identified the traditional thinking patterns of architects in China and predicted possible future roles for them as seen through the lens of architects of their personal philosophies. An alternative thinking pattern and design approach suited to OSM has been identified as a possible pathway to break through the constraints of discontinuous processes and programs of OSCM. The shortcomings of traditional approaches (including process, program and lack of skills and knowledge) have been highlighted. More attention needs to be paid to architects and the philosophies that underpin their practices. They are the critical specifiers in today’s off-site construction industry.

The traditional thinking patterns of architects in China has been conceptualized and identified as “architect centric” and “architectural work” mode. The alternative thinking pattern and design approach suited to OSM has been conceptualized and identified as a “building product” mode and “order and rules”. Architects need to respond to change and to these challenges. Many lack practical experience in manufacturing, construction, and the prediction of construction costs. These shortcomings restrict their decision-making abilities. This area is worth researching from the perspective of changing architects’ traditional mindsets to develop alternative design methodologies suited to OSM. Therefore, a new pathway is proposed at a conceptual level to help to transfer architects’ work mode from an “architectural work” mode to a “building product” mode. We are currently conducting case studies in Australia, focusing on the “order and rules”. The participants are professionals and organisations in the construction industry. The outcomes of our investigations will be published later. They will contribute to the development of alternative design methodologies suited to OSM, to bring tomorrow’s building components together in a seamless manner.

Acknowledgement

This study was funded by the “China Scholarship Council / The University of Newcastle Joint Funding Program”, the Chinese National Key Technology Research and Development Program: The research and demonstration on new industrialised construction technology of indemnificatory housing (2012BAJ16B03) led by Professor Hong Zhang from Southeast University. Acknowledgments are given to Associate Professor Willy Sher from the University of Newcastle and Adjunct Fellow David Chandler OAM from Western Sydney University for their assistance in supporting the upcoming case studies and the first author’s research.

DECLARATION OF CONFLICTING INTEREST The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article. FUNDING The author(s) received no financial support for the research, authorship, and/or publication of this article.

References

Barlow, J. & Ozaki, R. 2005, ‘Building Mass Customised Housing Through Innovation in the Production System: Lessons from Japan’, Environment and Planning A, vol. 37 no. 1, pp. 9-20, http://dx.doi.org/10.1068/a3579

Blismas, N.G. 2007, Off-Site Manufacture in Australia: Current State and Future Directions. Brisbane, Australia: Cooperative Research Centre for Construction Innovation

Blismas, N. & Wakefield, R. 2009, ‘Drivers, Constraints and the Future of Offsite Manufacture in Australia’, Construction Innovation, vol. 9 no. 1, pp. 72-83, http://dx.doi.org/10.1108/14714170910931552

Blismas, N.G., Pendlebury, M., Gibb, A. & Pasquire, C. 2005, ‘Constraints to the use of Off-Site Production on Construction Projects’, Architectural Engineering and Design Management, vol. 1 no. 3, pp. 153-162, http://dx.doi.org/10.1080/17452007.2005.9684590

Bottom, D., Gann, D., Groak, S. & Meikle, J. 1994, Innovation in Japanese Prefabricated House-Building Industries. London: Construction Industry Research and Information Association

Build-offsite Property Assurance Scheme (BOPAS) 2016, What is the Build-offsite Property Assurance Scheme (BOPAS)? [online] Available at: http://www.bopas.org/about [Accessed 17 July 2016]

Dean, J.W. & Susman, G.I. 1989, ‘Organizing for Manufacturable Design’, Harvard Business Review, vol. 67 no. 1, p. 28

Egan, J. 1998, The Egan Report- Rethinking Construction. London: DETR

Emmerson, H. 1962, Survey of Problems before the Construction Industry. London, UK: Ministry of Works

Evbuomwan, N.F.O. & Anumba, C.J. 1998, ‘An integrated Framework for Concurrent Life-Cycle Design and Construction’, Advances in Engineering Software, vol. 29 no. 7-9, http://dx.doi.org/10.1016/S0965-9978(98)00024-6

Fook, J. 2011, Creative Spaces for Qualitative Researching. Rotterdam: Sense Publishers

Fox, S., Marsh, L. & Cockerham, G. 2001, ‘Design for Manufacture: a Strategy for Successful Application to Buildings’, Construction Management and Economics, vol. 19 no. 5, pp. 493-502, http://dx.doi.org/10.1080/01446193.2001.9709625

Fox, S., Marsh, L. & Cockerham, G. 2002, ‘Constructability Rules: Guidelines for Successful Application to Bespoke Buildings’, Construction Management & Economics, vol. 20 no. 8, pp. 689-696, http://dx.doi.org/10.1080/01446190210163606

Gibb, A.G.F. 2000, Client’s Guide and Toolkit for Optimising Standardisation and Pre-Assembly in Construction. CIRIA Report CP/75. London: Construction Industry Research and Information Association

Gibb, A.G. 2001, ‘Standardization and Pre-Assembly-Distinguishing Myth from Reality Using Case Study Research’, Construction Management & Economics, vol. 19 no. 3, pp. 307-315, http://dx.doi.org/10.1080/01446190010020435

Gibb, A.G.F. & Isack, F. 2003, ‘Re-Engineering Through Pre-Assembly: Client Expectations and Drivers’, Building Research and Information, vol. 31 no. 2, pp. 146-160, http://dx.doi.org/10.1080/09613210302000

Gong, K. 2013, The Presentation on a New Off-Site Manufacture Technique. [meeting] (Personal communication, 10 April 2013)

Hamid, Z., Kamar, K.A.M., Zain, M., Ghani, K. & Rahim, A.H.A. 2008, ‘Industrialized Building System (IBS) in Malaysia: the Current State and R&D Initiatives’, Malaysia Construction Research Journal, vol. 2 no. 1, pp. 1-13

Harding, J. 1999, Responding to Pressure. Manufacturing Engineer, vol. 78 no. 5, p. 220

Housing Forum 2002, Homing in on Excellence – A Commentary on the use of Off-site Fabrication Methods for the UK Housebuilding Industry. London: Housing Forum

HMSO 1962, Survey of Problems before the Construction Industry. London: Ministry of Works

Jaillon, L. & Poon, C.S. 2009, ‘The Evolution of Prefabricated Residential Building Systems in Hong Kong: A Review of the Public and the Private Sector’, Automation in Construction, vol. 18 no. 3, pp. 239-248, http://dx.doi.org/10.1016/j.autcon.2008.09.002

Ji, Y.B. 2011, The Research and Development of Building Industrialisation in China. Beijing: China Architecture & Building Press

Luo, J.N., Zhang, H. & Sher, W. 2016, Construction Education in an Architecture School in China Based on Real-Life Project: from Virtuality to Reality. In: Natee Singhaputtangkul, 40th Australasian Universities Building Education Association (AUBEA) Conference. Cairns, Australia, 6-8 July 2016. Cairns: Central Queensland University

Miller, R., Strombom, D., Iammarino, M. & Black, B. 2009, The Commercial Real Estate Revolution. Hoboken: John Wiley & Sons

Nawi, M.N., Lee, A. & Nor, K. 2011, ‘Barriers to Implementation of the Industrialised Building System (IBS) in Malaysia’, The Built & Human Environment Review. vol. 4, pp. 22-35. ISSN 1759-0574

Neale, R.H., Price, A.D.F. & Sher, W.D. 1993, Prefabricated Modules in Construction: A Study of Current Practice in the United Kingdom. England: Ascot, Chartered Institute of Building

Pan, W., Gibb, A.G. & Dainty, A.R. 2007, ‘Perspectives of UK Housebuilders on the use of Offsite Modern Methods of Construction’, Construction Management and Economics, vol. 25 no. 2, pp. 183-194, http://dx.doi.org/10.1080/01446190600827058

Pan, W., Gibb, A.G. & Dainty, A.R. 2012, ‘Strategies for Integrating the use of Off-Site Production Technologies in House Building’, Journal of Construction Engineering and Management, vol. 138 no. 11, pp. 1331-1340, http://dx.doi.org/10.1061/(ASCE)CO.1943-7862.0000544

Peck, H. 1973, Designing for Manufacture. London, UK: Pitman

Sloan, A. & Bowe, B. 2014, ‘Phenomenology and Hermeneutic Phenomenology: The Philosophy, the Methodologies and using Hermeneutic Phenomenology to Investigate Lecturers’ Experiences of Curriculum Design’, Quality & Quantity, vol. 48 no. 3, pp. 1291-1303, http://dx.doi.org/10.1007/s11135-013-9835-3

Song, J., Fagerlund, W.R., Haas, C.T., Tatum, C.B. & Vanegas, J.A. 2005, ‘Considering Prework on Industrial Projects’, Journal of Construction Engineering and Management, vol. 131 no. 6, pp. 723-733, http://dx.doi.org/10.1061/(ASCE)0733-9364(2005)131:6(723)

Soubry, M. 2001, Bridge Detailing Guide. London: Construction Industry Research and Information Association

Sparkman, G., Groak, S., Gibb, A. & Neale, R. 1999, Adding value to construction projects through standardisation and pre-assembly. CIRIA Report R176. London: Construction Industry Research and Information Association

Taylor, J.E., Dossick, C.S. & Garvin, M. 2010, ‘Meeting the Burden of Proof with Case-Study Research’, Journal of Construction Engineering and Management, vol. 137 no. 4, pp. 303-311, http://dx.doi.org/10.1061/(ASCE)CO.1943-7862.0000283

Thanoon, W.A., Peng, L.W., Kadir, M.R.A., Jaafar, M.S. & Salit, M.S. 2003, The Experiences of Malaysia and Other Countries in Industrialised Building System. In: ICIBS, International Conference on Industrialised Building Systems. Kuala Lumpur, Malaysia, 10-11 September 2003, Kuala Lumpur: ICIBS

Thoresen, L. & Öhlén, J. 2015, ‘Lived observations: Linking the Researcher’s Personal Experiences to Knowledge Development’, Qualitative Health Research, vol. 25 no. 11, pp. 1589-1598, http://dx.doi.org/10.1177/1049732315573011

U.S. Department of Energy 2015, Solar Decathlon Contests. [online] Available at: http://www.solardecathlon.gov/2017/competition-contests.html [Accessed 10 July 2016]

Van Manen, M. 1997, Researching the Lived Experience: Human Science for an Action Sensitive Pedagogy, 2nd ed. Ontario: Althouse Press

Venables, T. 2004, Modern Methods of Construction in Germany: Playing the Off-Side Rule: Report of a DTI Global Watch Mission Report. London: DTI

Yin, R.K. 2013, Case Study Research: Design and Methods. 5rd Ed. Thousand Oaks, CA: Sage

Zhu, H.Y. 2013, The Discussion on Real-Life Project “Nanjing Jiangning Gallery of Modern Art”. [meeting] (Personal Communication, 12 December 2013)

Zhang, H. 2014, The Seminar on the Future Directions of Building Industrialization in China. [meeting] (Personal Communication, 15 May 2014)

Name Withheld 2011a. “Emergency Construction”. Interviewed by Jianing Luo. [audio record] Southeast University, 9 Sep 2011

Name Withheld 2011b. “Emergency Construction”. Interviewed by Jianing Luo. [audio record] Southeast University, 12 Sep 2011

Name Withheld 2011c. “Emergency Construction”. Interviewed by Jianing Luo. [audio record] Xinba factory, 11 Sep 2011